Catalog excerpts

THINK PARTS THINK TORNOS SIGMA 20 / SIGMA 32 Sliding headstock single spindle automatic lathe

Open the catalog to page 1

SIGMA 20 / SIGMA 32 IN A FEW WORDS! The only Swiss type sliding headstock machine being able to produce parts using the machining parameters of a fixed headstock machine. Simplicity ■ Mirror image kinematic. ■ Setting, adjustments 100% numerical. ■ 2 independent tool slides with fully compatible and interchangeable tooling. Performance ■ High productivity. ■ Identical headstock and counter spindle. ■ Independent roughing tool. ■ High power for high depth of cuts and large chip removal. Rigidity ■ Identical heavy duty machine construction, for main and counter operations. ■ Capable of...

Open the catalog to page 3

SIGMA 20 / SIGMA 32 A KINEMATIC GEARED TOWARD MULTI TASKING AND PERFORMANCE! Multi tasking ■ All the tool holders and accessories can be mounted on either tool slides. ■ Large array of heavy duty tool holders, allow for the machining of value added operations. ■ Up to 28 tool positions. 4 Performance Great capacity for chip removal. ■ Thanks to a roughing tool, it is possible to have up to 3 tools in the cut simultaneously. ■ SIGMA 20 / SIGMA 32

Open the catalog to page 4

When the SIGMA 20 / 32 is coupled with the Tornos bar loader SBF 532 it forms a high performing and complete manufacturing cell from a single source supplier. Rigidity ■ SIGMA 20 / 32 is the only lathe on the market that offers an identical rigidity in main and counter operations. ■ Identical headstock and counter spindle offer high power (6.0 / 7.5KW). SIGMA 20 / SIGMA 32 Simplicity Programming choice, ISO or TB-DECO (option). ■ Very simple ISO programming, thanks to the 2 channels concept which are completely independent. ■ Excellent ergonomics permitting to easily change and set the...

Open the catalog to page 5

SIGMA 20 / SIGMA 32 KINEMATICS GEARED TOWARDS TASKING AND PERFORMANCE S11 S41 Y1 Z1 Y4 X1 S1/ C1 X4 S4/C4 Z4 ■ ■ Mirror-like kinematics providing complete flexibility for front and back operations. ■ Open machining area provides optimum chip removal. ■ Tool settings all done numerically. ■ Independent coolant line on each tool. ■ Very easy access to tooling. ■ 6 Kinematics with two completely independent tool systems. Fully independent counter-spindle. SIGMA 20 / SIGMA 32

Open the catalog to page 6

SIGMA 20 / SIGMA 32 LATHE WITH 6 LINEAR AXES Z1 C1 S1 Sliding headstock Axis C sliding headstock (option) Main spindle X1 / Y1 S11 Platten 1 (main operations) Motorisation of tools – main operations X4 / Y4 S41 Platten 2 (back operations) Motorisation of tools – back operations Z4 C4 S4 Counter-spindle Axis C counter spindle (option) Counter spindle Y1 X4 S11 Y4 S41 Z1 S11 C1 S1 X1 C4 Z4 SIGMA 20 / SIGMA 32 S4 7

Open the catalog to page 7

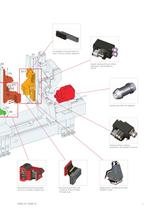

SIGMA 20 / SIGMA 32 MULTI TASKING: THE GUARANTEE OF HIGH FLEXIBILITY! Adjustable angle drilling or milling attachment. Can be mounted in main or counter operations. Thread whirling attachment. Can be mounted in main or counter operations. Z4 Double ended 2 spindles rotating attachment with spindles for ESX-16 collet. ■ ■ Attachments for operations such as polygon turning and thread whirling are easily integrated on the main spindle. ■ A total of 28 tool positions allowing multiple operations. According to how the machine is configured we can mount up to 12 rotating tools. ■ 8 The tool...

Open the catalog to page 8

Y1 Pre-settable turning tool holder for work in main or counter operations. X4 Double rotating drilling or milling attachment, with spindles for ESX-20. S11 Y4 S41 Z1 S11 C1 S1 X1 Double cone collet for headstock. C4 S4 Rotating milling or drilling attachment, with spindle for ESX-25. Motorized end working tool block for up to 4 rotating or steady tools. SIGMA 20 / SIGMA 32 End working tool block with 7 positions, Ø 20 mm bores, for steady tools. Roughing tool, activated by M codes. (SIGMA 32 only). 9

Open the catalog to page 9

SIGMA 20 / SIGMA 32 SIMPLICITY: THE GUARANTEE OF USER-FRIENDLY OPERATION! The new Tornos innovations coupled with tried and tested solutions will very quickly enable the operator to successfully use the Sigma 20 & Sigma 32. ■ ■ 10 ISO programming and TB-DECO as an option. ■ Very easy programming in ISO language thanks to the kinematic concept that uses two completely independent tool systems. TORNOS macro assistant simplifies cutting, bar feeding and bar end operations. ■ Entirely numeric tool setting and adjustment (all tools are fitted on 3 axes with no mechanical adjustments). ■ ■ Rapid...

Open the catalog to page 10

SIGMA 20 / SIGMA 32 RIGIDITY: THE GUARANTEE OF QUALITY MACHINING ■ In counter operations with as much as 3x the rigidity than its competitors the SIGMA 20 / SIGMA 32 allows for a profitability as much as 30% higher for parts where the machining operations are well balanced between main and counter operations. ■ Identical rigidity and identical spindles in main and counter operations. ■ The tool wear and the machining quality are directly linked to the machine rigidity. On the SIGMA 20 / 32, it is no longer necessary to favor the machining operations to the work done in main operations so to...

Open the catalog to page 11

SIGMA 20 / SIGMA 32 PERFOMANCE: THE GUARANTEE OF OPTIMUM PRODUCTIVITY ■ ■ 12 All machining operations, such as turning, radial drilling and milling and axial drilling can be executed as back-operations. ■ Inox 303 Ø 20 mm SIGMA 20 and SIGMA 32 have identical power and rigidity in main and counter operations. ■ 42 CR MO S4 Ø 22 mm The spindles offer a high clamping force. If needed it is also possible to mount a double cone collet on the headstock as well as a large opening (for over clamping) collet in counter operations. ■ AC. Inox 303 Ø 15 mm In main operations the power of the SIGMA 32...

Open the catalog to page 12

SIGMA 20 / SIGMA 32 TECHNICAL SPECIFICATIONS MAIN OPERATIONS SIGMA 20 SIGMA 32 Z1 axis travel (sliding headstock) mm / Inch 230 / 9.06 230 / 9.06 Bar capacity mm / Inch 20 (25.4) / 1 32 / 1.26 Main spindle speed max. rpm. 10’000 0-8’000 Main spindle power kW 3.7 / 5.5 6.0 / 7.5 Clamping collets F20; F25; F30 F25; F30; F37 Guide bush Fixed; turning; Habegger Fixed; turning; Habegger Number of tools for main operations 14 14 Speed of S11 rotating tools rpm. 10’000 10’000 Rotating tool section mm / Inch 16 x 16 / 0.63 x 0.63 16 x 16 / 0.63 x 0.63 Number of radial rotating tools 4 max. 4 max....

Open the catalog to page 13All TORNOS catalogs and technical brochures

-

BA 1008 HP

17 Pages

-

TISIS

16 Pages

-

Swiss GT

24 Pages

-

EvoDECO

15 Pages

-

SwissDECO

4 Pages

-

SwissNano

20 Pages

-

MultiSwiss

28 Pages

-

Swiss DT Range

13 Pages

Archived catalogs

-

BA 1008

17 Pages

-

CU 2007 / CU 3007

20 Pages

-

EvoDECO 20-32

12 Pages

-

EvoDECO 10-16

16 Pages

-

Swiss ST 26

16 Pages

-

CT 20

9 Pages

-

Robobar SBF

8 Pages

-

SAS 16.6

16 Pages

-

Brochure MultiSwiss 6x14

12 Pages

-

Brochure MultiSigma

16 Pages

-

Brochure Delta 38

4 Pages

-

Gamma 20

6 Pages

-

EvoDECO 20 / EvoDECo 32

12 Pages

-

MICRO 8/4 - MICRO 8/5

12 Pages

-

MICRO 7

8 Pages

-

DECO 26a

16 Pages

-

DECO 20a

16 Pages

-

EvoDECO 10 / EvoDECo 16

20 Pages

-

TORNOS SOLUTIONS

20 Pages

-

bar feeder ROBOBAR MSF-832/6

8 Pages

-

Multi Spindle MULTIDECO 20/8b

20 Pages

-

Single SpindleDECO 7/10a

12 Pages

-

Product range

14 Pages