Catalog excerpts

THINK PARTS THINK TORNOS SAS 16.6 Cam operated multispindle with programmable control.

Open the catalog to page 1

TORNOS PROVIDES SOLUTIONS TO HIGH-TECHNOLOGY INDUSTRIES, IN THE FOLLOWING SECTORS IN PARTICULAR : Watchmaking & Micromechanics

Open the catalog to page 2

SAS 16.6 World leader in small capacity multi-spindle turning machines To our Current and Future Customers… The quality of our work is your guarantee that Perhaps you are unfamiliar with the family of these machines will cycle 24 hours a day, Tornos Machine Tools. day after day, year after year ; and if there is It was in 1880 that the predecessors to Tornos a service problem our after sales service organiza- developed the first Swiss type sliding headstock tion will minimize your down time with a quick lathe in Moutier, Switzerland, and since then, men and women have built their businesses...

Open the catalog to page 3

PRESENTATION Cam-operated multi-spindle turning machine and programmable controller

Open the catalog to page 4

These advantages make the SAS 16.6 lathe With its speed of indexing and its amount of degrees of production (205°) the multispindle small parts. A better distribution of cutting operations. A more accurate spindle speed. 205° of work zone to obtain a production of up to 80 parts per minute.

Open the catalog to page 5

Rigidity The replacement of the traditional mechanical finger locking of the carrier with a combination of Hirth toothed coupling gears, the development of a 3-bearing front support of the spindle and the addition of a pressure lubricated spindle, gives you the following advantages : ■ Increased axial and radial rigidity. Increased precision on length and diameter. Increased tool life. Increased surface finish. Increased reliability of the machine. Guarantee tolerances on certain operations by eliminating the shaving operation. Precision Precision is defined as the capability of a machine to...

Open the catalog to page 6

Optionally Spindle stop ■ Cross drilling and milling. Eccentric end drilling for complex parts. Counter turret Up to 3 counter-operations can be performed on free time. This will allow you to complete : ■ Very difficult parts. Eliminate secondary operations. Electronic handwheels Which users of automatic multispindle lathes Pick-off spindle have never complained about fine adjustment or Possibility to have 2 pick-off spindles in pos. 3 dimension corrections requiring the machine to and 6 that give you the opportunity to work be stopped and time spent on adjustment. in counter-operation and to...

Open the catalog to page 7

Equipment interchangeability Today more than 300 attachments are available in our catalogue going from drilling and forming, Toolholder for shaving to more complex operations like polygoning and thread milling. These attachments are interchangeable between the AS 14, SAS 16, SAS 16 DC and now the new SAS 16.6. Polygon and thread milling attachment Independent stationary spindle 3 1 2 Recess attachment Forming toolholder

Open the catalog to page 8

Double live spindle attachment Cross slide Thread rolling attachment Thread rolling head Stationary drilling attachment

Open the catalog to page 9

User friendly With the evolution of the indexing system of The operation of the machine is monitored by the spindle carrier in relation to the old “Malte a Fanuc (Power Mate) with a detailed diagnostic cross”, we can offer you the following : Smooth indexing. Programmable features : An increase of the product life. Spindle speed. Acceleration speed. The low mass of the spindle carrier gives us Camshaft speed. the smoothness of indexing. Tornos is the world- Auxiliary function (like drill safeties, chip conveyor, broken tool detection, bar loaders, etc.). wide leader of the multispindles for...

Open the catalog to page 10

Technical features Installed behind the regular stock reel, it Bars running in an oil bath. automatically feeds the machine with bar stock Fanuc control. to maximize time savings. Bar storage : 110 bars of 7 mm. Possible productivity up to 50 p / min. Minimum inertia. The “oil bath” design guarantees a production follow-up up to 50 p / min. without vibration and without the bars being “clawed” by the turret. As a result the new MSF 316 integrated loader increases further the quality of parts made on an SAS 16.6. Summing up, the Robobar MSF 316 provides you with less space requirement,...

Open the catalog to page 11

AUTOMATIC BAR LOADER Secondary machine-collet “Chucker” Secondary machine-collet “Chucker” attachments is similar to the bar machine. The ln today’s market, especially in the automotive loading and part clamping system is specific to and bearing industries, the use of pre-formed each application. and blanked parts are increasing. Tornos has now developed the multispindle SAS 16.6 collet “Chucker”. The installation of the tooling and

Open the catalog to page 12

TECHNICAL CHARACTERISTICS TECHNICAL CHARACTERISTICS Number of spindles Max. capacity : Range 1 - Ratio 1 Range 2 - Ratio 2 Range 3 - Ratio 3 Production Speed Max. length of feed stroke with standard cam Max. part length with standard cam Max. length of feed stroke with cam for long part Max. part length with long part cam Number of cross-slides Travel of the cross-slides Number of independent advances Travel of the independent slide Travel of the central slide Amount of working degree Spindle motor Max. torque Constant torque up to 1’500 rpm Constant power from 1’500 rpm (50 % ED) Camshaft...

Open the catalog to page 13

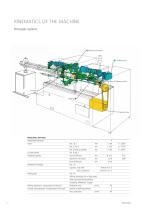

KINEMATICS OF THE MACHINE Principals options Working movement Camshaft drive Tapping return Spindle drive PRINCIPALS OPTIONS Independent Advances Travel Counter-spindle Clamping capacity : Differential threading Drilling quills Slotting attachment : transportation of the part Counter turret operation : transportation of the part 4 Pos.1 & 2 mm 1 x 60 Pos. 3, 4 & 5 mm 2 x 45 Pos. 6 (pick-up spindle) mm 1 x 100 Pos. 6 and 3 Up to 5’000 rpm mm Ø 12,5 Special for short parts mm Ø 16 Up to 8’000 rpm mm Ø 10 Pos. 2-6 Capacity : mild steel M 8 (M 10 x 1) Capacity : brass, aluminium M10 (M 12 x 1)...

Open the catalog to page 14

MACHINE SPECIFICATIONS GENERAL CHARACTERISTICS Machine length with electrical cabinet Machine length with 3 m (10 feet) stock reel Width, including the guard Height over the guard Height over the tower light Weight of the machine only Weight of the electrical cabinet Coolant pump pressure Coolant tank capacity Power rating Pneumatic operating pressure Standard color 2 shades

Open the catalog to page 15All TORNOS catalogs and technical brochures

-

BA 1008 HP

17 Pages

-

TISIS

16 Pages

-

Swiss GT

24 Pages

-

EvoDECO

15 Pages

-

SwissDECO

4 Pages

-

SwissNano

20 Pages

-

MultiSwiss

28 Pages

-

Swiss DT Range

13 Pages

Archived catalogs

-

BA 1008

17 Pages

-

CU 2007 / CU 3007

20 Pages

-

EvoDECO 20-32

12 Pages

-

EvoDECO 10-16

16 Pages

-

Swiss ST 26

16 Pages

-

CT 20

9 Pages

-

Robobar SBF

8 Pages

-

Brochure MultiSwiss 6x14

12 Pages

-

Brochure MultiSigma

16 Pages

-

Brochure Delta 38

4 Pages

-

Gamma 20

6 Pages

-

EvoDECO 20 / EvoDECo 32

12 Pages

-

MICRO 8/4 - MICRO 8/5

12 Pages

-

MICRO 7

8 Pages

-

SIGMA 20 / SIGMA 32

16 Pages

-

DECO 26a

16 Pages

-

DECO 20a

16 Pages

-

EvoDECO 10 / EvoDECo 16

20 Pages

-

TORNOS SOLUTIONS

20 Pages

-

bar feeder ROBOBAR MSF-832/6

8 Pages

-

Multi Spindle MULTIDECO 20/8b

20 Pages

-

Single SpindleDECO 7/10a

12 Pages

-

Product range

14 Pages