Catalog excerpts

TORNOS TECHNOLOGIES IBERICA Pol. Ind. El Congost Avda. St Julia, 206 Nave 8 E-08400 GRANOLLERS Tel.:+34 93 846 59 43 Fax:+34 93 849 66 00 E-mail:comercial.tti@tornos.chTORNOS TECHNOLOGIESITALIA SRL Via Cesare Pavese. 21 I-20090 OPERA / MI Tel.:+39 02 45 77 17 01 Fax:+39 02 45 70 16 48 E-mail:contact@tornos.itTORNOS TECHNOLOGIESUS CORPORATION 70 Pocono Road P.O. Box 325 US-BROOKFIELD CT 06804 Tel.:01 203 775-4319 Fax:01 203 775-4281 E-mail:contact@tornosusa.com TORNOS SHANGHAIREPRESENTATIVE OFFICE Tower B, Office 512-513 Far East International Plaza No. 319 Xianxia Road CN-SHANGHAI 200335 Tel.:+86 21-62351235 Fax:+86 21-62351938TORNOS TECHNOLOGIES ASIA LIMITED Unit 4, G/F, Transport City Building 1-7 Shing Wan road Tai Wai, Shatin N.T., Hong Kong Tel.:+852 2691 2633 +852 2691 1633Fax:+852 2691 2133TORNOS TECHNOLOGIES CZECH REPUBLIC c/o Teximp S.R.O. Mladoboleslavsha 908 CZ- 19700 Prague Tel.: +420-2-850 3180 Fax: +420-2-850 3182 TORNOS-TECHNOLOGIESDEUTSCHLAND GmbH Karlsruher Str. 38 D-75179 PFORZHEIM Tel.:+49 (0)7231/ 910 70 Fax:+49 (0)7231/ 910 750 E-mail:contact@tornos.deTORNOS TECHNOLOGIESFRANCE Bote postale 330 ST-PIERRE EN FAUCIGNY F-74807 LA ROCHE S / FORON CEDEX Tel.:+33 (0)4 50 038 333 Fax:+33 (0)4 50 038 907 E-mail:contact@tornos.frTORNOS TECHNOLOGIESUK Ltd Tornos House Whitwick Business Park Coalville UK-Leicestershire LE67 4JQ Tel.:+44 (0)1530 513100 Fax:+44 (0)1530 814212 E-mail:sales@tornos.co.uk TORNOS S.A.Rue Industrielle 111CH-2740 MOUTIERTel.:+41 (0)32 / 494 44 44Fax:+41 (0)32 / 494 49 03E-mail: contact@tornos.chwww.tornos.ch Edition 09/2005 THINK PARTS THINK TORNOS >

Open the catalog to page 1

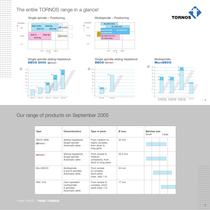

TORNOSspecialises in the manufacture of auto-matic lathes for turning parts from bars or billets.The company now offers a wide range ofproducts, with three main ranges broken down into the automatic single-spindle, tailstock DECO [a-line] and [s-line] lathes, the PNC M > ULTI DECOmultispindle lathes and the SAS 16.6 multispindle, cam-operated lathes.With the TB-DECO, the DECO and M > ULTI DECOmachines are fitted with a programming system that defies all competition and allows the ope- rators to exceed the conventional limits achieved with CNC. Thanks to its vast experience and...

Open the catalog to page 2

M > ULTI DECO HighMiddle Low HighMiddle Low 32/6cM > ULTI DECO 20/8bM > ULTI DECO 32/6iM > ULTI DECO 20/6bM > ULTI DECO 20/8 [2x4]M > ULTI DECO 20/6be >

Open the catalog to page 3

Technical characteristicsDECO 7/10aDECO 13aDECO 20aDECO 26a Max. bar capacity7/10 mm13 (16) mm20 (25,4) mm26 (32) mmMax. turning length with fixed guide bush60 (90) mm180 mm200 mm240 mm Spindle speed 100-100-100-100- 16000 rpm12Ғ000 rpm10000 rpm8Ғ000 rpm Max. motor power 3,7 kW3,7 kW5,5 kW7,5 kW Number of tools on the tool frame8101010 Number of positions for end units3444 Counter-spindle 100-100-100-100- speed12000 rpm12Ғ000 rpm8000 rpm6Ғ000 rpm Number of back working positions4677 Number of numerical >

Open the catalog to page 4

700 Bars 3200: length 4055Bars 3850: length 4705 Bars 4200: length 5055 1100 1364 Width: 1540 2200 DECO 26a: version 10 axes only 8 axeswith counter-spindle 10 axeswith counter-spindle & combined end attachment > Technical characteristicsDECO 8spDECO 20s Max. bar capacity8 (10) mm20 (25,4) mm Max. turning length17,5 mm200 mm Spindle speed 15000 rpm200-10Ғ000 rpm Max. motor power2,2/3,7 kW3,7/5,5 kW Total number of tools2014Number of positions for end units44 Counter-spindle speed15000 rpm200-10Ғ000 rpmNumber of back working positions68Number of numerical axes (simultaneously)5 (7/C axis)6...

Open the catalog to page 6

Key benefits Key benefits High precision. Single machine with all essentials. Flexibility and fast part change (CNC). High productivity under 2 sec./part. Strength. High precision 0.006 mm. Flexibility and quick change-over guaranteed (CNC technology). > 16 Key benefits Key benefits Good work distribution over 8 positions. Motorized spindle (= ideal speed for eachposition). [2x4] version possible. High precision. Twin counter-spindles (highly complex partsat high output). Controlled part unloading. Integrated palletizing. > Key benefits Integrated solution: machine + bar feeder +chip...

Open the catalog to page 9

THINK TORNOS The TB-DECO environment 20 THINK PARTS An integrated solutionoptimised for all DECO andM Compatibility with marketstandards > ULTI DECOmachines. A universal programminginterface for all DECO andM Standard ISO code pro-gramming. > ULTI DECO, to guaranteeperfect integration of both worlds into a single produc- tion unit. A user-friendly, intuitive andvisual software package at your disposal.Entirely developed by TORNOS,this software enables simple, quick, logical and ergonomic programming parts on your PC.This is undoubtedly the bestsolution on the market for reducing component...

Open the catalog to page 11

Technical characteristicsSAS 16.6 Max. capacity16 (17) mm Max. part length with standard cam52/75 mm Spindle Speed8'000 rpm Max. motor power7,5 kW Variator of spindle and camshaft speedsYes Number of cross slides6 Main tool slideYes Number of independent slides4 Number of counter-spindles1 Amount of working degree205ְ Monitoring systemFanuc Locking of spindle carrierDenture Hirth Second operation machine with collet chuckYes >

Open the catalog to page 12

Training centre In order to allow each buyer to makefull use of all the capabilities of our machines, a centre of vocational training is at his disposal.Professionals of TB technique and ofvocational training give an introduc- tion, which guarantees the full adapta- tion of machining procedures to the workpiece and the application of know-how based on our rich expe- rience in domains as various as auto- mobile industry, aeronautics, elec- tronics, medicine and dentistry. Technology centre Your challenges are ours. In order toapply this maxim, TORNOS puts at your disposal a test centre,...

Open the catalog to page 14All TORNOS catalogs and technical brochures

-

BA 1008 HP

17 Pages

-

TISIS

16 Pages

-

Swiss GT

24 Pages

-

EvoDECO

15 Pages

-

SwissDECO

4 Pages

-

SwissNano

20 Pages

-

MultiSwiss

28 Pages

-

Swiss DT Range

13 Pages

Archived catalogs

-

BA 1008

17 Pages

-

CU 2007 / CU 3007

20 Pages

-

EvoDECO 20-32

12 Pages

-

EvoDECO 10-16

16 Pages

-

Swiss ST 26

16 Pages

-

CT 20

9 Pages

-

Robobar SBF

8 Pages

-

SAS 16.6

16 Pages

-

Brochure MultiSwiss 6x14

12 Pages

-

Brochure MultiSigma

16 Pages

-

Brochure Delta 38

4 Pages

-

Gamma 20

6 Pages

-

EvoDECO 20 / EvoDECo 32

12 Pages

-

MICRO 8/4 - MICRO 8/5

12 Pages

-

MICRO 7

8 Pages

-

SIGMA 20 / SIGMA 32

16 Pages

-

DECO 26a

16 Pages

-

DECO 20a

16 Pages

-

EvoDECO 10 / EvoDECo 16

20 Pages

-

TORNOS SOLUTIONS

20 Pages

-

bar feeder ROBOBAR MSF-832/6

8 Pages

-

Multi Spindle MULTIDECO 20/8b

20 Pages

-

Single SpindleDECO 7/10a

12 Pages