Catalog excerpts

High-performance machining centres

Open the catalog to page 1

CU 2007 CU 3007 The CU 2007 and CU 3007 are ultra flexible, available in a 3,4,5 and 7-axis version, and are designed to enable a range of machining solutions to be tackled with ease. Maximum number of tools

Open the catalog to page 2

Maximum number of tools

Open the catalog to page 3

The CU 2007 and CU 3007 combine dynamic performance and outstanding reliability with Swiss expertise and precision, enabling Tornos to offer its customers a truly innovative solution. The comprehensive standard equipment, combined with the expertise of the company's engineers, create the optimal conditions for producing complex workpieces. Rigidity • Cast iron structure providing high precision as well as excellent durability. • The design of the machine means it can perform extremely demanding machining operations. • The work table can support a heavy weight (250 kg). Medical & Dental...

Open the catalog to page 4

• Ergonomic and easily accessible work zone. • The walls are gently inclined to ensure optimum evacuation of chips directly towards the chip conveyor*. • A washing system manages the chips. • Easy access to all units. • Oil mist extraction systems.* • High-performance machining with up to 7* axes. • Powerful high-performance milling spindle (12,000, 20,000 and 40,000 rpm). • Spindle with thermal regulation. • 60 m/min rapid feed rate. • Centralised cyclical lubrication system.* • Greater precision and perfect finishes guaranteed. • Axial acceleration above 1 G. Flexibility • Functional...

Open the catalog to page 5

Capacity for 16, 24 or 40 tools Tool magazine and tool changer system On the standard version, the CU 2007/3007 are equipped with a rapid and reliable tool changer system with a dual-position automated arm. 24 HSK-E40 tools can be loaded in the tool magazine, ensuring very low cycle times for optimal productivity. • Capacity for 16,24 or 40 tools (optional). • Accurate and robust system. • Tool changeover < 0.8 s. • Chip-to-chip time < 3 s. • HSK-E40 tool interface. • Tool diameter up to 60 mm. • Adjacent space of 110 mm. • Tool length up to 200 mm.

Open the catalog to page 6

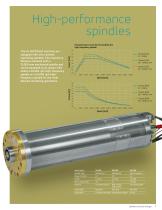

Power/torque curves for the 40,000 rpm high-frequency spindle The CU 2007/3007 machines are equipped with ultra-precise machining spindles. The machine is fitted as standard with a 12,000 rpm mechanical spindle and can be equipped as an option with either a 20,000 rpm high-frequency spindle or a 40,000 rpm high-frequency spindle for the most delicate machining operations. Spindle type High frequency Increased torque High torque High speed Increased speed Tool holder Lifetime lubricated Lifetime lubricated Air/oil Spindle and tool changer

Open the catalog to page 7

Clamping and mechanical design Acceleration above 1 G 470 mm Z axis • Simple and robust cast iron structure. • Column with one vertical axis. • Reduced maintenance and increased durability. • Compact design. • Increased rigidity and excellent thermal stability. • Linear guides are used to ensure accurate positioning, quick movement and allow an increased machining load. • The column structure and large bases have been designed for extremely demanding tasks. • The distance between the spindle head and the column has been optimised to ensure the spindle is geometrically accurate. Drive...

Open the catalog to page 8

Simple, efficient numerical control The Fanuc OiMD numerical control system enables optimal simultaneous management of 3 to 4 axes. Management of 5 simultaneous axes can be selected as an option for more complex machining operations (Fanuc 31iB5). The numerical control is placed on an adjustable ergonomic support which can be easily tilted by the operator. Options: • Rigid tapping. • All control contour mode II (200 blocks). • Nano-smoothing. • Sister tool management. • Large diameter tool management. Tornos offers clamping solutions to suit your needs The 5-axis CU 2007 and 3007 guarantee...

Open the catalog to page 9

7-axis CU 2007 / 3007 Machining from bar stock In this special configuration, available as an option, the miller is fitted with a 5-axis divider. A second divider is installed on the machine, equipped with rotary axes and a linear axis that allow it to be converted into a bar feeding device as required. These two additional axes allow the machine to compete with more high-end turning/milling centres. In fact, the second divider enables the machine to not only feed the spindle with the correct bar length, but also to finish the part, specifically its sixth face. Once the front of the...

Open the catalog to page 10

Machining of the front face 5 Machining with 5 axes (4 simultaneous axes) 6th face machining with the pickup unit Machining from bar stock

Open the catalog to page 11

Automation Pick & Place system To increase the productivity and autonomy of your production tool, Tornos offers an ultra-highperformance automatic Pick & Place system. The workpieces to be machined are automatically transported by the gripper arm from the magazine to the clamping system. Once milling is complete, the workpieces are placed back on the mobile pallet. Loading is quick and the pallets can contain up to 200 workpieces depending on the size. Loading/unloading collet Magazine with automatic opening Blum Z-Nano tool measurement sensor Magazine with automatic opening Modular mobile...

Open the catalog to page 12

Tornos CU 2007 robot for 24/7 machining A unique solution that displays all the knowhow of Tornos Milling with the integration of a robotised cell for greater productivity and greater machine autonomy. The 6-axis robot means workpieces can be loaded/unloaded and flipped. An additional gripping system is used to manage workpiece pallets. The integration of this robot offers the CU 2007 extreme autonomy of movement, notably Loading, unloading, palletising, turning and : reloading the machining unit with unparalleled precision. The device can even handle the intermediate storage and the...

Open the catalog to page 13

Peripherals and options Oil filtration and chip removal system The CU 2007/3007 are equipped with a 200-litre tank which may be accompanied by a 580 mm or 1100 mm-high chip conveyor and a paper filter with automatic feed. These peripheral options offer optimal chip management Chip tray and conveyor High-pressure system for central cooling For improved productivity and optimal machining quality, Tornos offers a high-pressure central cooling option. Our 18, 42 and 70 bar high-pressure units offer a wide range to meet your needs.

Open the catalog to page 14All TORNOS catalogs and technical brochures

-

BA 1008 HP

17 Pages

-

TISIS

16 Pages

-

Swiss GT

24 Pages

-

EvoDECO

15 Pages

-

SwissDECO

4 Pages

-

SwissNano

20 Pages

-

MultiSwiss

28 Pages

-

Swiss DT Range

13 Pages

Archived catalogs

-

BA 1008

17 Pages

-

EvoDECO 20-32

12 Pages

-

EvoDECO 10-16

16 Pages

-

Swiss ST 26

16 Pages

-

CT 20

9 Pages

-

Robobar SBF

8 Pages

-

SAS 16.6

16 Pages

-

Brochure MultiSwiss 6x14

12 Pages

-

Brochure MultiSigma

16 Pages

-

Brochure Delta 38

4 Pages

-

Gamma 20

6 Pages

-

EvoDECO 20 / EvoDECo 32

12 Pages

-

MICRO 8/4 - MICRO 8/5

12 Pages

-

MICRO 7

8 Pages

-

SIGMA 20 / SIGMA 32

16 Pages

-

DECO 26a

16 Pages

-

DECO 20a

16 Pages

-

EvoDECO 10 / EvoDECo 16

20 Pages

-

TORNOS SOLUTIONS

20 Pages

-

bar feeder ROBOBAR MSF-832/6

8 Pages

-

Multi Spindle MULTIDECO 20/8b

20 Pages

-

Single SpindleDECO 7/10a

12 Pages

-

Product range

14 Pages