Website:

TIPPER TIE TECHNOPACK GmbH

Website:

TIPPER TIE TECHNOPACK GmbH

Group: Protein

Catalog excerpts

Product Portfolio INJECTION ] MASSAGING | BRINE PREPARATION | PORTIONING | COATING | FRYING | COOKING | SEARING 1 GRILLING | PROOFING | BAKING | CHILLING ! FREEZING ! INSPECTION

Open the catalog to page 1

Patented technologies for every stage of the food processing chain JBT supplies technology solutions for the global food industry, offering integrated solutions across the entire food processing continuum, from meat, seafood and poultry, to fruit and vegetables, baked goods, and convenience foods. We can provide you with flexible, customised solutions for injection, massaging, brine preparation, portioning, coating, frying, cooking, baking, chilling, freezing and inspection that run like clockwork, deliver maximum uptime, match your toughest hygiene demands and make your processing...

Open the catalog to page 2

Injection, Massaging, Brine preparation

Open the catalog to page 3

Schröder Marination Technology Injection technology Massaging technology Brine preparation The processing principle of the IMAX technology is based on classic injection curing by means of hollow needles. This is where knowhow regarding needle type, inlet and exit holes and needle stitch pattern plays a decisive role. The brine/emulsion to be injected is carried directly to the product by a system of pumps and pipes. Pork, beef, boneless products, bone-in meat, poultry and fish can be injected. The operating principle of MAX technology is based on the horizontal mounting of a rotating paddle...

Open the catalog to page 4

Injection Schröder IMAX A new benchmark in injection technology. What sets us apart is our knowledge of the perfect combination of components. Whether manifolds, injection needles, pumps or brine feeds – each component is researched in detail, designed and coordinated to work seamlessly together. In conjunction with intelligent electronics, this combination guarantees the following: Options: Tenderizer head Meat-in Meat injection (HVB) Integration in process visualization software VISMAX Inline weighing igh levels of performance and precise injection accuracy H Optimal brine distribution in...

Open the catalog to page 5

Massage technology for increased productivity. This is the key to higher water retention and a higher yield at the slicer through better slice cohesion. Available sizes from 600kg up to 6.000kg. Thanks to active massaging of the meat using special paddles, SCHRODER MAX technology allows the following in an extremely short period of time. ■ Intra- and extramuscular protein activation ■ Significantly improved water retention ■ Active incorporation of brine in an extremely short time ■ Efficient utilisation of drum capacity Options: ■ Different paddle styles for softer/harder treatment ■...

Open the catalog to page 6

Schroder BRIMAX Special brine preparation system for mixing, cooling and holding the brine for the marination process. The thorough preparation of brine is a critical part of the overall injection and processing concept. This is much more than simple mixing. Electronically controlled and monitored processes, individually configured recipe programs, effective cooling and independent additive intake guarantee the following: ■ Standardization of brine making process ■ Swift insertion of additives ■ Homogenous mixing process ■ Repeat accuracy for recipes ■ Effective cooling Options: ■ Agitator...

Open the catalog to page 7

Other Marination Equipment Schröder PREMAX For the production of high-quality cooked ham, massaging the muscles is an important part of the process. Protein is activated which ensures optimum bonding. This process supported by the Schröder PREMAX machines for mechanical treatment. PSM 650 – Curing press Processing muscles with a hard structure needs special attention, the lack of flexibility makes the forming and filling process more difficult. In order to balance out the different muscle textures, the PSM 650 is used. The roller pairs break down the internal structures without destroying...

Open the catalog to page 8

Portioning Systems

Open the catalog to page 9

DSI® 800 Series Portioner The 8 cutter Portioning System from DSI delivers groundbreaking functionality and versatility in a compact, cost-effective and easy-to-use package. Designed for: High volume portioning; a precision machine for intense, high-accuracy cuts, using a new generation scanner for effortless all-in-one fat trimming. Key features: ■ High yield ■ Reduced labour ■ More throughput ■ Matches your product mix and orders on any given day Applications: ■ Whole muscle chicken strips and tenders ■ Nuggets and double-weight portions ■ Chicken thigh meat chunks/portions ■ “Perfect”...

Open the catalog to page 10

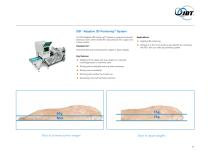

DSI® Adaptive 3D Portioning™ System The DSI Adaptive 3D Portioning™ System is a precise horizontal band saw slicer, which divides the input product into a upper and a lower portion. Designed for: Horizontal slicing to achieve portion weight or equal weights. Applications: ■ Adaptive 3D portioning ■ Achieve 2, 4, 6 or more portions per butterfly by combining the A3D with our water jet portioning system Key features: ■ Adapting to the shape and size variation on unsorted incoming product to maximise yield ■ Slicing product optimally and only when necessary ■ Slicing more consistently ■...

Open the catalog to page 11

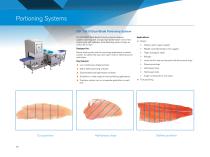

DSI® DB20 Dual-Blade Portioning System The DSI DB20 Dual-Blade Portioning System delivers superior scanning with a single, high-performance sensor that continuously self-calibrates while detecting product shape as well as fat vs. lean. Designed for: Simple linear poultry and fish portioning applications; a perfect solution for plants that may have water, noise or electrical power restrictions. Key features: ■ Low-maintenance blade portioner ■ DSI Q-LINK portioning software ■ Sophisticated yield optimisation software ■ Suitable for a wide range of linear portioning applications ■ Dual-lane...

Open the catalog to page 12

DSI® Waterjet portioning More possibilities than you ever imagined

Open the catalog to page 13

Coating Systems

Open the catalog to page 14

Stein® high performance coating systems From the inventor of coating equipment JBT’s range of Stein® coating systems are synonymous with continuous, conveyorised batter and breading applications. Since introducing the first commercially successful batter and breading applicator in 1955, the Stein brand has continued to lead the industry with innovative and robust equipment, and now has the largest installed base of coating systems in the world. The main features and benefits of the Stein coating systems are: The main features and benefits of the GYRoCOMPACT spiral freezer, chiller and...

Open the catalog to page 15All TIPPER TIE TECHNOPACK GmbH catalogs and technical brochures

-

TTVac

4 Pages

-

TTSealH

4 Pages

-

TTBag

4 Pages

-

TT1815-TT1512

4 Pages

-

TN4000 Family

4 Pages

-

TN3004

4 Pages

-

TTStick

4 Pages

-

TD60

2 Pages

-

TCV-TCNV

4 Pages

-

TCV1590

2 Pages

-

TC4357

2 Pages

-

TAN

2 Pages

-

SwiStickXXL

4 Pages

-

SVU6800

4 Pages

-

SVF1800

4 Pages

-

SV4800

4 Pages

-

SPR

2 Pages

-

Signature Throat Series

4 Pages

-

Signature Gate Series

4 Pages

-

SBCS

2 Pages

-

Rucker

4 Pages

-

RS4204

4 Pages

-

Rota-Matic

4 Pages

-

Rota-Clip

4 Pages

-

PTNV

2 Pages

-

Plastic Clip Clippers

4 Pages

-

KDCR

2 Pages

-

KDCM-DCM

4 Pages

-

KDCMA

4 Pages

-

ICV600.BC400

2 Pages

-

Econo Line Clippers

4 Pages

-

Double Clippers

4 Pages

-

600-700

4 Pages

-

MAX3000/6000 Massagers

4 Pages

-

IMAX HIGHline injectors

6 Pages

-

BRIMAX brine preparation

4 Pages

-

IMAX ECOline Injectors

4 Pages