Catalog excerpts

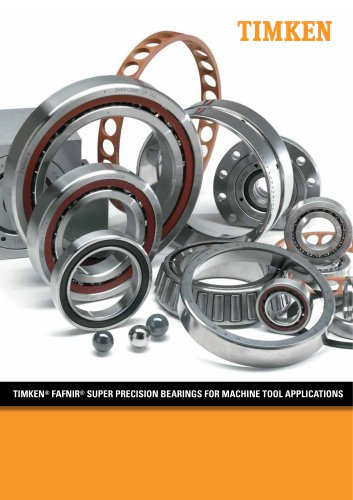

TIMKEN® FAFNIR® SUPER PRECISION BEARINGS FOR MACHINE TOOL APPLICATIONS

Open the catalog to page 1

ENGINEERING Bearing Selection Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Determination of Applied Loads and Bearing Analysis . . . . . . . . . . . . . . . Bearing Reactions, Load Ratings and Life . . . . . . . . . . . . . . . . . . . . . . . . . . Permissible Operating Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Run-In Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 3

TIMKEN MACHINE TOOL CATALOG ABOUT THE TIMKEN COMPANY The leading authority on tapered roller bearings, Timken today applies its deep knowledge of metallurgy, tribology and mechanical power transmission across a variety of bearings and related systems to improve reliability and efficiency of machinery and equipment all around the world. Timken (NYSE: TKR; www.timken.com) engineers, manufactures and markets bearings, gear drives, belts, chain and related products, and offers a spectrum of powertrain rebuild and repair services. To view more Timken catalogs, go to www.timken.com/catalogs for...

Open the catalog to page 4

Introduction ABOUT THIS CATALOG Timken offers an extensive range of bearings and accessories in both imperial and metric sizes. For your convenience, size ranges are indicated both in millimeters and inches. Contact your Timken sales representative to learn more about our complete line for the special needs of your application. USING THIS CATALOG We are committed to providing our customers with maximum service and quality. This catalog contains dimensions, tolerances and load ratings, as well as an engineering section describing fitting practices for shafts and housings, internal...

Open the catalog to page 5

TIMKEN MACHINE TOOL CATALOG PURCHASER’S EXCLUSIVE REMEDY/SELLER’S EXPRESS LIMIT OF LIABILITY Purchaser’s exclusive remedy for any warranty claim, or for any claim arising out of the purchase or use of our products, shall be the replacement of said products. We will replace our products, without charge to the purchaser, f.o.b. our point of shipment. We will not be liable for any consequential, incidental, or other damages sustained by purchaser, including but not limited to, loss of profits or revenue, loss of use of product, cost of capital, cost of substituted product, facilities,...

Open the catalog to page 6

SHELF LIFE AND STORAGE OF GREASE-LUBRICATED BEARINGS AND COMPONENTS To help you get the most value from our products, Timken provides guidelines for the shelf life of grease-lubricated ball and roller bearings, components and assemblies. Shelf life information is based on Timken and industry test data and experience. When removing a product that is not individually packaged from a bulk pack container, the container should be resealed immediately after the product is removed. The storage area temperature should be maintained between 0° C (32° F) and 40° C (104° F); temperature fluctuations...

Open the catalog to page 7

TIMKEN MACHINE TOOL CATALOG Inasmuch as Timken is not familiar with a customer’s particular storage conditions, these guidelines are strongly suggested. However, the customer may very well be required by circumstance or applicable government requirements to adhere to stricter storage requirements. Most bearing types are typically shipped protected with a corrosionpreventive compound that is not a lubricant. Such bearings may be used in oil-lubricated applications without removal of the corrosion-preventive compound. When using some specialized grease lubrication it is advisable to remove...

Open the catalog to page 8

Bearing Selection Bearing Selection Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Determination of Applied Loads and Bearing Analysis . . . . 32 Bearing Reactions, Load Ratings and Life . . . . . . . . . . . . . . . 38 Permissible Operating Speed . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Run-In Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 Heat Generation and Dissipation . . . . . . . . . . . . . . . . . . . . . . . 60...

Open the catalog to page 9

TIMKEN MACHINE TOOL CATALOG

Open the catalog to page 10

ENGINEERING THE BEARING SELECTION PROCESS TIMKEN® BEARINGS Timken provides an extensive variety of rolling bearing types and sizes – to the extent that customers need not look elsewhere. Knowing that the bearing is often the most critical component within a moving assembly, Timken engineers take great care to ensure the customer is receiving maximum value when a Timken® bearing is selected to perform a given function. With the acquisition of the Fafnir® brand, Timken can provide the proper bearing for virtually any motion-control application. With more than a century of proven experience in...

Open the catalog to page 11

Typical considerations in machine design also include optimization of controllable variables affecting application performance: Bearing design. Installation and handling requirements of the bearing, as well as shaft and housing preparation. Presence of adequate sealing for the exclusion of contaminants; types of foreign materials possible. Lubricating method (lubrication type and delivery system). Bearing shaft and housing arrangement; shaft and housing material. Maintenance procedures and intervals. Boundary (or fixed) conditions that should be taken into consideration include: External...

Open the catalog to page 12

Tapered roller bearing Spherical roller bearing Thrust tapered roller bearing Cylindrical roller bearing Thrust cylindrical roller bearing Thrust spherical roller bearing Tapered roller bearing Thrust tapered roller bearing Pure radial load Pure axial load Combined load Ball bearing Thrust ball bearing Cylindrical roller bearing Thrust cylindrical roller bearing Spherical roller bearing Thrust spherical roller bearing Ball bearing Thrust ball bearing Moment load High stiffness Quiet running Locating position (fixed) Non-locating position (floating) Table 1. Relative operating...

Open the catalog to page 13All TIMKEN catalogs and technical brochures

-

National® Industrial Seals

716 Pages

-

TIMKEN® ECOTURN® SEAL

2 Pages

-

Timken® Lubricants

6 Pages

-

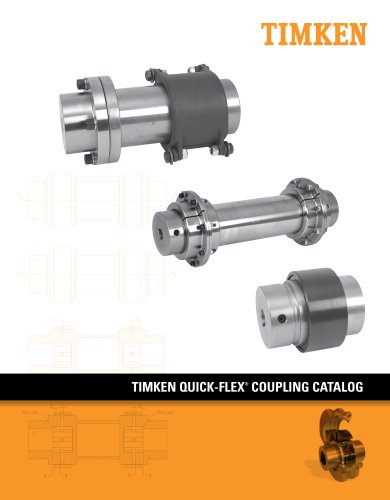

Quick-Flex Couplings

68 Pages

-

Matched Bearing Assemblies

16 Pages

-

Cylindrical Roller Bearings

108 Pages

-

AP Bearings

84 Pages

-

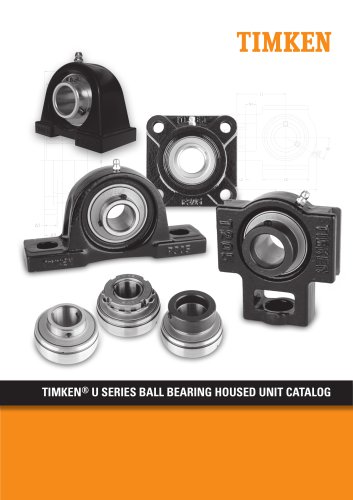

UC Series Ball Housed Units

24 Pages

-

Type E Housed Units

40 Pages

-

Ball Housed Units

180 Pages

-

SNT Plummer Blocks

120 Pages

-

SAF Housed Units

126 Pages

-

Thrust Bearings

138 Pages

-

Quick-Flex Coupling Catalog

68 Pages

-

Bearing interchange guide

163 Pages

-

UC-SERIES

24 Pages

-

Quick-Flex Coupling

64 Pages

-

Timken Drives Roller Chain Catalog

112 Pages

-

Commercial Vehicle Catalog

417 Pages

-

Industrial Maintenance Manual

157 Pages

-

Timken SAF Housed Unit Catalog

126 Pages

-

Timken Ball Housed Unit Catalog

180 Pages

-

Timken® SNT Plummer Block Catalog

120 Pages

-

BALL BEARINGS

214 Pages

Archived catalogs

-

COMPETENCYBASED TRAINING

5 Pages

-

Spherical Roller Bearings

236 Pages

-

Timken Engineering Manual

210 Pages

-

Timken Ball Bearings Catalog

217 Pages

-

Timken Industrial Seals

40 Pages

-

Ball Bearings

6 Pages

-

IsoClass Bearings

8 Pages

-

Maintenance Tools

16 Pages

-

Industrial Products

56 Pages

-

Precision Rotary Assemblies

2 Pages

-

Ceramic Bearings

2 Pages