Catalog excerpts

Timken Engineering Manual Timken Engineering Manual Bearings • Steel • Power Transmission Systems • Precision Components • Gears • Seals • Lubrication • Industrial Services • Remanufacture and Repair www.timken.com Price: USD $75 15M 10-11: Order No. 10424 Timken® and Where You Turn® are registered trademarks of The Timken Company. • © 2011 The Timken Company • Printed in U.S.A.

Open the catalog to page 1

ENGINEERING Manual Index Timken Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Shelf Life Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Bearing Selection Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Bearing Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Cages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 2

TIMKEN. WHERE YOU TURN. Turn to Timken to move ahead of the competition and stand out as a leader in your industry. When you turn to us, you receive more than high-quality products and services; you acquire a worldwide team of highly trained and experienced associates, eagerto helpyou keep production rates high and downtime low. Whether it is a wheel assembly for a family vehicle, bearings outfitted for a deep-sea oil drilling rig, repair services for rail bearings or steel for an aircraft engine shaft, we supply the products and services you need that help keep the world turning. FRICTION...

Open the catalog to page 3

TECHNOLOGY THAT MOVES YOU Innovation is one of our core values, and we're known for our ability to solve engineering challenges. We focus on improving performance in the most difficult applications, and we're passionate about creating technical solutions and services that help your equipment perform faster, harder, smoother and more efficiently. • People, attracting and hiring scholars, engineers and specialists from across the globe who are experts in mechanical power transmission, antifriction bearing design, tribology, metallurgy, clean steel production, precision manufacturing,...

Open the catalog to page 4

i The Timken brand stands for quality, innovation I We take pride in the quality of our work, and you gain the peace-of-mind of knowing that each box 1 contains an industry-trusted product. As our founder, r Henry Timken, said, "Don't set your name to anything you will ever have cause to be ashamed of." We continue this mindset through the Timken Quality Management System (TQMS). With TQMS, we promote continuous quality improvements in our products and services to our global operations and supply chain networks. It helps us ensure that we're consistently applying quality management...

Open the catalog to page 5

ABOUT THIS MANUAL We are committed to providing our customers with maximum service and quality. This engineering manual provides assistance in selecting the right bearing foryour application. It contains guidelines for determining the: • Appropriate bearing type. • Predicted bearing life for specific application loading and environmental conditions. • Bearing setting. • Bearing tolerances. • Shaft and housing fits. Maximum operating temperatures. • Bearing torque. • Proper bearing lubrication. ISO and ANSI/ABMA, as used in this publication, refer to the International Organization for...

Open the catalog to page 6

SHELF LIFE AND STORAGE Timken guidelines for the shelf life of grease-lubricated rolling bearings, components and assemblies are set forth below. Shelf life information is based on test data and experience. Shelf life should be distinguished from lubricated bearing/ component design life as follows: SHELF LIFE POLICY Shelf life of the grease-lubricated bearing/component represents the period ottime priorto use or installation. The shelf life is a portion of the anticipated aggregate design life. It is impossible to accurately predict design life due to variations in lubricant bleed rates,...

Open the catalog to page 7

Most bearing shipped protected preventive compound applications without preventive compound. When using some specialized grease lubrications, it is advisable to remove the corrosion-preventive compound before packing the bearings with suitable grease. Some bearing types in this catalog, are pre-packed with general purpose grease suitable for their normal application. Frequent replenishment of the grease may be necessary for optimum performance. Care must be exercised in lubricant selection, however, since different lubricants are often When specified by the customer, other bearings may be...

Open the catalog to page 8

Where more complex bearing applications are involved, your Timken engineer should be consulted. The following topics are covered within this manual: • Bearing design types. • Cage design types. • Life analysis procedure. • Bearing tolerances. ► Fitting practice and mounting recommendations. • Operating temperatures. • Speed ratings. • Seal design options. Timken is a leader in the advancement of bearing technology. Expert craftsmanship, well-equipped production facilities, and a continuing investment in technology programs ensure that our products are synonymous with quality and...

Open the catalog to page 9

BEARING SELECTION PROCESS BEARING SELECTION PROCESS The first step in bearing selection is to identify the best bearing type for the application. Each bearing type has advantages and disadvantages based on its internal design. Table 1, on page 10, ranks the different bearing types on various performance characteristics. The next step is to assess the bearing size constraints including the bore, outside diameter (O.D.) and width. This is done by defining the minimum shaft diameter, maximum housing diameter and available width for the bearing in the application. At this point, bearings may be...

Open the catalog to page 10

BEARING SELECTION PROCESS BEARING TYPES BEARING TYPES Tapered roller bearing Thrust tapered roller bearing Cylindrical roller bearing Thrust cylindrical roller bearing Spherical roller bearing Thrust spherical roller bearing Radial ball bearing Thrust ball bearing Angular contact ball bearing TABLE 1. RELATIVE OPERATING CHARACTERISTICS OF VARIOUS BEARING TYPES 10 TIMKEN ENGINEERING MANUAL

Open the catalog to page 11All TIMKEN catalogs and technical brochures

-

National® Industrial Seals

716 Pages

-

TIMKEN® ECOTURN® SEAL

2 Pages

-

Timken® Lubricants

6 Pages

-

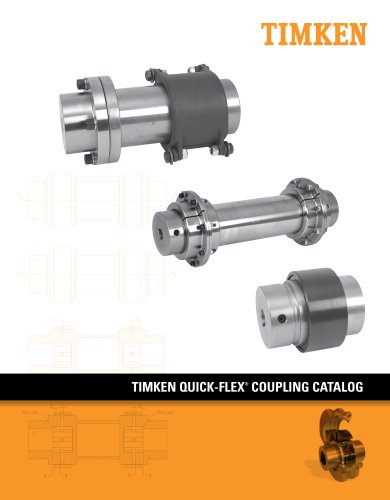

Quick-Flex Couplings

68 Pages

-

Matched Bearing Assemblies

16 Pages

-

Cylindrical Roller Bearings

108 Pages

-

AP Bearings

84 Pages

-

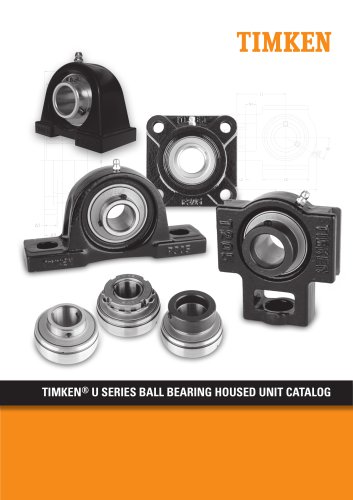

UC Series Ball Housed Units

24 Pages

-

Type E Housed Units

40 Pages

-

Ball Housed Units

180 Pages

-

SNT Plummer Blocks

120 Pages

-

SAF Housed Units

126 Pages

-

Thrust Bearings

138 Pages

-

Quick-Flex Coupling Catalog

68 Pages

-

Bearing interchange guide

163 Pages

-

UC-SERIES

24 Pages

-

Quick-Flex Coupling

64 Pages

-

Timken Drives Roller Chain Catalog

112 Pages

-

Commercial Vehicle Catalog

417 Pages

-

Industrial Maintenance Manual

157 Pages

-

Timken SAF Housed Unit Catalog

126 Pages

-

Timken Ball Housed Unit Catalog

180 Pages

-

Timken® SNT Plummer Block Catalog

120 Pages

-

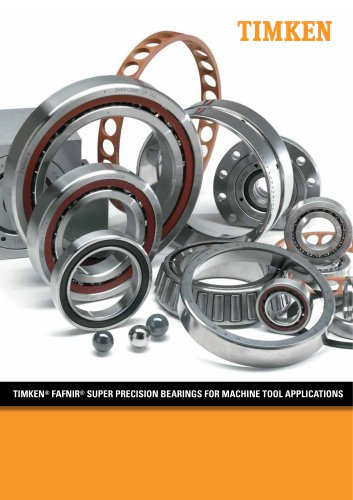

BALL BEARINGS

214 Pages

Archived catalogs

-

COMPETENCYBASED TRAINING

5 Pages

-

Spherical Roller Bearings

236 Pages

-

Timken Ball Bearings Catalog

217 Pages

-

Timken Industrial Seals

40 Pages

-

Ball Bearings

6 Pages

-

IsoClass Bearings

8 Pages

-

Maintenance Tools

16 Pages

-

Industrial Products

56 Pages

-

Precision Rotary Assemblies

2 Pages

-

Ceramic Bearings

2 Pages