Catalog excerpts

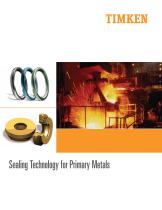

Sealing Technology for Primary Metals

Open the catalog to page 1

Timken Industrial Seals for Primary Metals Smelting and steel making is a tough job in an even tougher environment. Extreme temperatures and high levels of contamination can make or break your equipment and productivity. Choose from our selection of sealing products and Prophet software diagnostic tool to help improve the performance of your bearings and equipment while reducing downtime and maintenance costs. Software Package Timken’s complete line of high-performance oil seals for primary metals applications helps improve machine efficiency, bearing life and productivity while reducing...

Open the catalog to page 2

TIMKEN INDUSTRIAL SEALS Surface Speed Spring Material Misalign & Runout in.@ fpm (mm @ mps) General purpose, split seal Cover plate required Over 300,000+ sizes, readily available General purpose seal Solid or split design Reverse bevel lip design prevents lip rollover Reinforced rubber OD Single and dual lip configurations available General purpose assembled seal Heavy-duty metal outer case Single and dual lip configurations available High-temperature, assembled seal Heavy-duty metal outer case THERMO-CERAM™ sealing element Ideal for abrasive environments Grease lubricated...

Open the catalog to page 3

TIMKEN INDUSTRIAL SEALS Other Equipment

Open the catalog to page 4

SEALING TECHNOLOGY FOR PRIMARY METALS TIMKEN INDUSTRIAL SEALS Models = Seal model or style on pages 2 & 5 Coke Ovens Blast Furnace Sasic Oxygen Furnace RH Vac Degasser Dual-Stand Reheat Furnace Slab Caster Universal Mill Annealing Line (Model 58 Finished Products

Open the catalog to page 5

TIMKEN INDUSTRIAL SEALS Non-Contact Bearing Isolators Timken Metallic Isolator Standard Material • Meets NEMA MG 1-2003 • Surpasses IEEE 841-2001 test standards • Conforms to API 610 • No arbor press required for installation • No internal metal-to-metal contact • Bronze** construction • Filled PTFE unitizing ring • Fluoroelastomer O-rings standard • Unique microcellular filter technology • Protects against severely dusty environments • Meets NEMA MG 1-2003 • Surpasses IEEE 841-2001 test standards • Conforms to API 610 • No arbor press required for installation • No internal metal-to-metal...

Open the catalog to page 6

SEALING TECHNOLOGY FOR PRIMARY METALS TIMKEN INDUSTRIAL SEALS Table 1 - Shaft Data Table 5 - Recommended Shaft Lead Corner Hardness Rockwell C 30 to 40 (Rockwell C 45 minimum will provide extra protection against damage during handling or assembly) (Plunge grind is no machine lead, scratches, dents, recommended as corrosion, pits or other surface defects most satisfactory) Surface speed Formula: Feet-Per-Min. = Shaft Dia. (in) x RPM x 0.262 Meters-Per-Sec. = Shaft Dia. (mm) x RPM x 0.0000524 Safe speed 1. Shaft finish depends on* 2. Misalignment and runout 3. Amount and...

Open the catalog to page 7

Turn to Timken Like all of our products and services, our seals are backed by our leading technical support and a vast distribution network. Turn to Timken today for a full line of Timken industrial seals that help improve bearing, equipment and bottom-line performance. Visit www.timken.com/industrialseals to learn more. Distributed by The Timken Company. Timken® Service Parts are carefully chosen from select manufacturers. Keep clean and dry. TIMKEN The Timken team applies their know-how to improve the reliability and performance of machinery in diverse markets worldwide. The company...

Open the catalog to page 8All TIMKEN catalogs and technical brochures

-

National® Industrial Seals

716 Pages

-

TIMKEN® ECOTURN® SEAL

2 Pages

-

Timken® Lubricants

6 Pages

-

Quick-Flex Couplings

68 Pages

-

Matched Bearing Assemblies

16 Pages

-

Cylindrical Roller Bearings

108 Pages

-

AP Bearings

84 Pages

-

UC Series Ball Housed Units

24 Pages

-

Type E Housed Units

40 Pages

-

Ball Housed Units

180 Pages

-

SNT Plummer Blocks

120 Pages

-

SAF Housed Units

126 Pages

-

Thrust Bearings

138 Pages

-

Quick-Flex Coupling Catalog

68 Pages

-

Bearing interchange guide

163 Pages

-

UC-SERIES

24 Pages

-

Quick-Flex Coupling

64 Pages

-

Timken Drives Roller Chain Catalog

112 Pages

-

Commercial Vehicle Catalog

417 Pages

-

Industrial Maintenance Manual

157 Pages

-

Timken SAF Housed Unit Catalog

126 Pages

-

Timken Ball Housed Unit Catalog

180 Pages

-

Timken® SNT Plummer Block Catalog

120 Pages

-

BALL BEARINGS

214 Pages

Archived catalogs

-

COMPETENCYBASED TRAINING

5 Pages

-

Spherical Roller Bearings

236 Pages

-

Timken Engineering Manual

210 Pages

-

Timken Ball Bearings Catalog

217 Pages

-

Timken Industrial Seals

40 Pages

-

Ball Bearings

6 Pages

-

IsoClass Bearings

8 Pages

-

Maintenance Tools

16 Pages

-

Industrial Products

56 Pages

-

Precision Rotary Assemblies

2 Pages

-

Ceramic Bearings

2 Pages