Catalog excerpts

ThyssenKrupp Magnettechnik Displacement system for holding and transporting sheet metal When handling equipment for sheet bars or thin sheet metal was designed in the past, grapplers or pneumatic vacuum devices were used for preference to date. An electrically switchable magnet system now makes it possible to design smaller units which also have a high adhesive power. This avoids also the considerable disadvantages of these grapplers and suction cups, the mechanical wear and tear, the cost-intensive conditioning of air and the restricted possibilities of use. The small dimensions at the same time as a high adhesive power mean that this system can be deployed universally, e.g. in the case of very short or heavily moulded sheet bars as well as in the case of those which have many punchouts or holes. The small dimensions are possible thanks to the use of modern magnetic materials such as samarium cobalt. This increases the specific adhesive power and thus also the safe transportation of heavy and thick iron items. The chosen geometry makes the removal of the sheet bar possible in two different ways, either longitudinally or transversely. In addition, this system can be used for lifting or pushing. The magnet system has its full adhesive power when it is not supplied with electricity, and only when there is a defined flow of electricity through the integrated coil the system becomes non-magnetic. In accordance with VDE 0580 (Association of German Electrical Engineers) (air gap = 0.1 mm), the minimum adhesive power - without electricity - is 30 to 40 kp, depending on the type. On the other hand, it is possible to increase further the adhesive power of the magnet system by reversing the direction of current. We supply three different types of the above-mentioned systems: they are different both in their adhesive power as well as in their duty cycle. Depending on type, the duty cycle is approx. 75%, 40% or 20%. These types are specially suitable for the following applications: lifting applications for transporting heavy and thick iron items, such as rails, pallets, gas cylinders, etc. removal and transportation applications of sheet metal blanks, shaped items and sheet bars from pressing, punching, sheet bar loaders and feeding these parts to robots. The high specific adhesive power of this generation of systems means that there are also further applications in other branches of industry. 1

Open the catalog to page 1

ThyssenKrupp Magnettechnik Technical data: Dimensions: a.) b.) length * width * height 90 mm 30 mm 25 mm 100 mm 30 mm 25 mm With 75% switch-on period: Supply voltage: 35...42 V DC dependent on the control electronics Compensation voltage 20°C: approx. 22 V DC Compensation current: 600 mA Adhesive power with an air gap of 0.1 mm and a 3 mm thick piece of sheet metal: With 40% switch-on period: Supply voltage: 35...42 V DC dependent on the control electronics Compensation voltage 20°C: approx. 24 V DC Compensation current: 800 mA Adhesive power with an air gap of 0.1 mm and a 3 mm thick piece...

Open the catalog to page 2All ThyssenKrupp Magnettechnik catalogs and technical brochures

-

Filter magnets

2 Pages

-

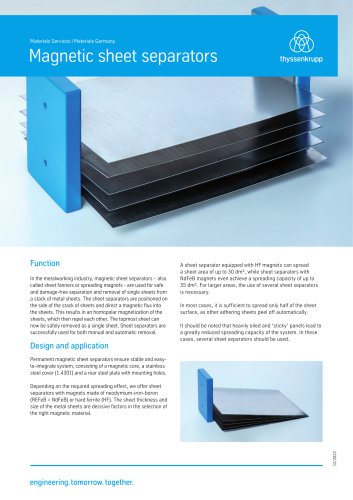

Magnetic sheet separators

3 Pages

-

Pot magnets

8 Pages

-

Hard ferrite magnets

4 Pages

-

Magnets move us

9 Pages

-

Spreading Magnets

8 Pages

-

holding magnets

40 Pages

-

AlNiCo-Magnets

40 Pages