Catalog excerpts

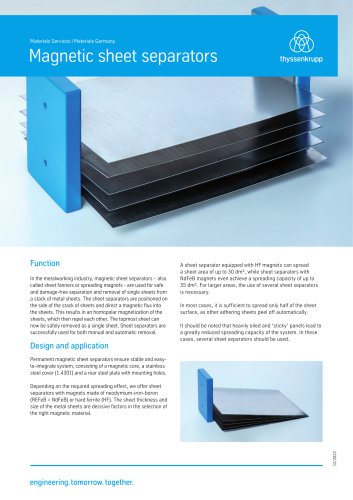

Materials Services I Materials Germany Magnetic sheet separators Function In the metalworking industry, magnetic sheet separators – also called sheet fanners or spreading magnets - are used for safe and damage-free separation and removal of single sheets from a stack of metal sheets. The sheet separators are positioned on the side of the stack of sheets and direct a magnetic flux into the sheets. This results in an homopolar magnetization of the sheets, which then repel each other. The topmost sheet can now be safely removed as a single sheet. Sheet separators are successfully used for both manual and automatic removal. A sheet separator equipped with HF magnets can spread a sheet area of up to 30 dm², while sheet separators with NdFeB magnets even achieve a spreading capacity of up to 35 dm². For larger areas, the use of several sheet separators is necessary. In most cases, it is sufficient to spread only half of the sheet surface, as other adhering sheets peel off automatically. It should be noted that heavily oiled and ‘sticky’ panels lead to a greatly reduced spreading capacity of the system. In these cases, several sheet separators should be used. Permanent magnetic sheet separators ensure stable and easyto-integrate system, consisting of a magnetic core, a stainless steel cover (1.4301) and a rear steel plate with mounting holes. Depending on the required spreading effect, we offer sheet separators with magnets made of neodymium-iron-boron (REFeB = NdFeB) or hard ferrite (HF). The sheet thickness and size of the metal sheets are decisive factors in the selection of the right magnetic mate

Open the catalog to page 1

thyssenkrupp Materials Services | Materials Germany | Permanent magnetic sheet separators Arrangement Sheet separators are arranged differently depending on the space available and the removal situation. One proven method is a diagonal arrangement and on opposite sides. It is recommended that the sheets are first removed horizontally from the magnets and then transported upwards. If this is not feasible in your application, vertical removal of the sheets is also possible. The sheet separator should be 10–20% higher than the stack of sheets, but at least approx. 50 mm higher. A single sheet...

Open the catalog to page 2

thyssenkrupp Materials Services | Materials Germany | Permanent magnetic sheet separators Product range Available at short notice Sheet separators with hard ferrite magnets Part no. Sheet separators with NdFeB magnets Part no. Other dimensions are also available on request. In addition to our standard program, we also offer individual solutions for permanent magnetic as well as electromagnetic sheet separators. We will be happy to advise you on this. Contact thyssenkrupp Magnettechnik Branch of thyssenkrupp Schulte GmbH Am Hellweg 7 44805 Bochum, Germany T: +49 234 622014-00...

Open the catalog to page 3All ThyssenKrupp Magnettechnik catalogs and technical brochures

-

Filter magnets

2 Pages

-

Pot magnets

8 Pages

-

Hard ferrite magnets

4 Pages

-

Magnets move us

9 Pages

-

Spreading Magnets

8 Pages

-

holding magnets

40 Pages

-

AlNiCo-Magnets

40 Pages