Catalog excerpts

Oil-Free LM Guide for Special Environments Optimum for use under a vacuum environment (up to 106 Pa) where oil cannot be used Newly developed: Dry Lubrication S-Compound Film Low particle generation, low outgassing TOKYO. JAPAN

Open the catalog to page 1

Oil-Free LM Guide for Special Environments THK-EX50 (martensitic stainless steel) Structure of the Oil-Free LM Guide for Special Environments # Structural characteristics 1. Uses stainless steel All components are made of stainless steel for special environment. Special solvent Is used to de-grease this This achieves The product does not use any grease, but adopts a highly reliable Dry Lubrication S-Compound Film. # What is Dry Lubrication S-Compound Film Dry Lubrication S-Compound Film is a fully dry lubricant developed for use under atmospheric to high-vacuum environments. It has superior...

Open the catalog to page 2

The Oil-Free LM Guide for special environments exerts superbly low frlctional properties In atmospheric to vacuum -Dry Lubrication S-Compound Film (vacuum) -Dry Lubrication S-Compound Film (atmosphere) The Oil-Free LM Guide for special environments exerts a lower level of particle generation than conventional vacuum grease lubricants. Particle diameter (ium) ■ 0.1 or larger With vacuum grease (LM Guide) I Particle diameter (fjrn) ■ 0.1 or # Long Service Life The Oil-Free LM Guide for special environments has a longer service life than conventional dry lubrication. Contact surface pressure...

Open the catalog to page 3

Accuracy Standard Accuracy of the Oil-Free LM Guide for special environments is classified into Precision (P), Super Precision (SP) and Ultra Precision (UP). Radial clearance of the Oil-Free LM Guide for special environments is defined with the values in the table below.

Open the catalog to page 4

Shoulder height of the mounting surface and the corner radius Normally, the mounting surface for the LM block and the LM rail has a datum plane on the side face in order to allow easy installation and highly accurate The corner of the mounting surface must be machined to have a recess, or machined to be smaller than the corner radius "r," to prevent interference with the chamfer of the LM block or the LM rail. Qlblerance in parallelism between 2 rails The following table shows the tolerance in parallelism (P) between 2 rails. Qlblerance in vertical level between 2 rails The following table...

Open the catalog to page 5

Model SR-MSV/W Dimensional table for models SR-MSV/W Note 1 : If you desire a product other than the model numbers indicated above, contact THK. Note 2: For durability of the Oil-Free LM Guide for special environments, contact THK. Example of model number coding Number of rails used With this model, a single-rail unit constitutes one set (i.e., the required number of sets when 2 rails are used in parallel is 2).

Open the catalog to page 6

Standard length and maximum length of the LM rail The following table shows the standard length and the maximum length of the LM rail of the Oil-Free LM Guide for special environments. If the overall rail length exceeds the maximum length, contact THK. For dimension G if you require a special length, we recommend using the dimensions in the table. If dimension G is longer, the respective part tends to become unstable after installation, which may negatively affect the accuracy. Standard length and maximum length of the LM rail Note 1 : If you desire a rail length larger than the maximum...

Open the catalog to page 7

EFÜ=¡ln£ Oil-Free LM Guide for Special Environments • Pulling out the LM block from the LM rail will cause balls to fall, or damage the Dry Lubrication S-Compound Film when reattaching the LM block. If it is necessary to remove the LM block from the LM rail, contact THK. • Do not disassemble the parts. Doing so may cause entrance of dust or a functional loss. • Tilting the LM block or the LM rail may cause it to fall by its own weight. • Do not drop or hit the LM Guide. Doing so may cause injury. It may also cause failure or breakage. Applying an impact to the product may cause a functional...

Open the catalog to page 8All THK catalogs and technical brochures

-

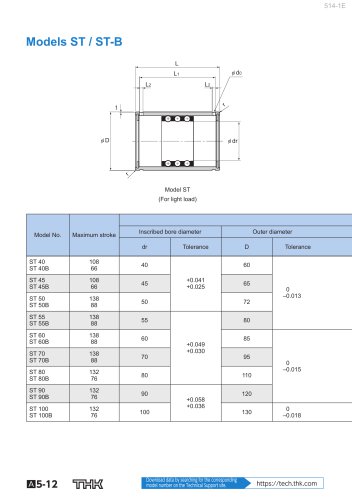

Models ST / ST-B

2 Pages

-

Predicting the Rigidity

5 Pages

-

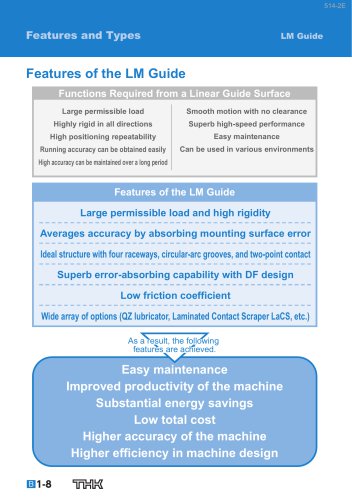

Features of the LM Guide

16 Pages

-

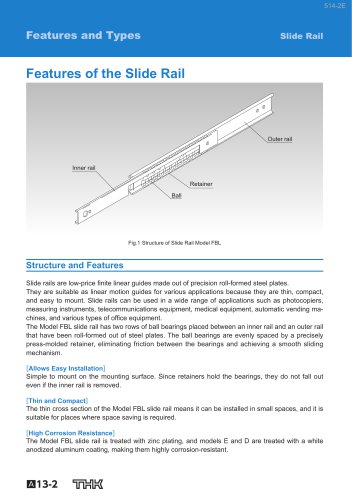

Features of the Slide Rail

1 Pages

-

PCT/PC

40 Pages

-

Models SHS-C and SHS-LC

2 Pages

-

Models SSR-XW and SSR-XWM

2 Pages

-

Models SSR-XV and SSR-XVM

2 Pages

-

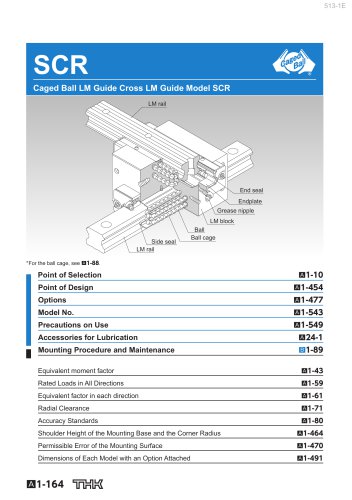

SCR

8 Pages

-

LM ACTUATOR GL

20 Pages

-

HDR

28 Pages

-

RSX

6 Pages

-

Fix Stages

4 Pages

-

Finite Stroke LM Guide EPF

12 Pages

-

LM ACTUATOR GL-N

28 Pages

-

LM Actuator TY

16 Pages

-

Clean-Room Actuator Model CSKR

20 Pages

Archived catalogs

-

Model SSR-XTB

2 Pages

-

Catalogue Caged Ball LM Guide

23 Pages

-

Low Price Actuator Model VLA

16 Pages

-

LM Guide Actuator Model KR

92 Pages

-

Ball Spline Series

24 Pages

-

Cross-Roller Ring Series

28 Pages

-

High-temparature LM Guide Series

28 Pages

-

Model HR Separate Type

20 Pages

-

LM Actuator Model TY

16 Pages

-

Guide Ball Bush LG

8 Pages

-

Limited-stroke LM Guide

12 Pages

-

LM Actuator Model GL-N

28 Pages

-

RoD Actuato

12 Pages

-

Product Ordering Guide

8 Pages

-

LM Guide Actuator KR

68 Pages