Catalog excerpts

Medium Torque Type Ball Spline Models LT, LF, LT-X, LF-X, LFK-X, and LFH-X Ball Spline nut Snap ring Seal Spline shaft Fig.1 Structure of Medium Torque Type Ball Spline Model LT Mounting Procedure and Maintenance Cross-sectional Characteristics of the Spline Shaft Equivalent factor Clearance in the Rotation Direction Accuracy Standards Maximum Manufacturing Length by Accuracy

Open the catalog to page 1

Medium Torque Type Ball Spline Structure and Features With the medium torque type Ball Spline, the spline shaft has two to three crests on the circumference, and along both sides of each crest, two rows of balls (four or six rows in total) are arranged to hold the crest so that a reasonable preload is applied. The rows of balls are held in a special resin retainer incorporated in the spline nut so that they smoothly roll and circulate. With this design, balls will not fall even if the nut is removed from the spline shaft. [No Angular Backlash] Two rows of balls facing one another hold a...

Open the catalog to page 2

Types and Features [Types of Spline Nuts] Cylindrical Type Ball Spline Model LT The most compact type with a straight cylindrical spline nut. When transmitting a torque, a key is driven into the body. Flanged Type Ball Spline Model LF The spline nut can be attached to the housing via the flange, making assembly simple. It is optimal for locations where the housing may be deformed if a keyway is machined on its surface, and where the housing width is small. Specification Table

Open the catalog to page 3

Medium Torque Type Ball Spline Model LT-X Miniature Ball Spline Model LF-X Miniature Ball Spline Ball Spline The nut is more compact than that of the current Model LT thanks to the new circulating pathways. The outer diameter of the nut is the same as that of the linear bushing. The Model LT-XL is suitable for moment loads, torque, and overhung loads that exceed those tolerated by the Model LT-X. The nut is more compact than that of the current Model LF thanks to the new circulating pathways. The outer diameter of the nut is the same as that of the linear bushing. The Model LF-XL is...

Open the catalog to page 4

Model LFK-X Miniature Ball Spline The flange is similar to the Model LF-X, but flattened in four places. Compared to models with round flanges, its core height is lower, and it allows for more compact designs. The Model LFK-XL is suitable for moment loads or torque and overhang loads that exceed those tolerated by the Model LFK-X. Model LFH-X Miniature Ball Spline The flange is similar to the Model LF-X, but flattened in two places. Compared to models with square flanges, its core height is lower, and it allows for a lighter overall design. The Model LFH-XL is suitable for moment loads or...

Open the catalog to page 5

Medium Torque Type Ball Spline [Types of Spline Shafts] Precision Solid Spline Shaft (Standard Type) The raceway of the spline shaft is precision ground. It is used in combination with a spline nut. Ball Spline Special Spline Shaft THK manufactures a spline shaft with thicker ends or thicker middle area through special processing at your request. Hollow Spline Shaft (Type K) A drawn, hollow spline shaft is available for requirements such as piping, wiring, air-vent and weight reduction. Hollow Spline Shaft (Type N) A drawn, hollow spline shaft is available for requirements such as piping,...

Open the catalog to page 6

Spline nut dimensions Model No. Greasing hole Note) Models LT4 and 5 do not have a retainer. Do not remove the shaft from the spline nut. (It will cause balls to fall off.) ○: indicates model numbers for which high temperature types are available (with metal retainer; service temperature: up to 100℃). (Example) LT20 A CL+500L H High temperature symbol Model number coding Symbol for clearance Accuracy symbol in the rotational direction (*3) (*2) Symbol for spline shaft (*4) Number of spline nuts Contamination protection Overall spline shaft length (*5) on one shaft accessory symbol (in mm)...

Open the catalog to page 7

Medium Torque Type Ball Spline Ball Spline Spline shaft diameter Basic torque rating Basic Load Rating Static permissible moment Spline Nut Spline shaft g kg/m MA.1 indicates the permissible moment value in the axial direction when a single spline nut is used, as shown in the figure above. ** MA.2 indicates the permissible moment value in the axial direction when two spline nuts in close contact with each other are used, as shown in the figure above. For details on the maximum lengths of ball spline shafts by accuracy, please see A3-123.

Open the catalog to page 8

Model LF 4- φ d1 through hole, φ d2 counter bore depth h 4- φ d1 through hole, φ d2 counter bore depth h ° 45 Model LF16 or greater Spline nut dimensions Outer diameter Flange diameter Greasing hole Mounting hole Note) ○: indicates model numbers for which high temperature types are available (with metal retainer; service temperature: up to 100℃). (Example) LF30 A CL+700L H High temperature symbol Model number coding Symbol for clearance Accuracy symbol in the rotational direction (*3) (*2) Symbol for spline shaft (*4) Number of spline nuts Contamination protection Overall spline shaft...

Open the catalog to page 9

Medium Torque Type Ball Spline M A.1 Ball Spline Spline shaft diameter Basic torque rating Basic load rating Static permissible moment Spline Nut Spline shaft g kg/m Note) **MA.1 indicates the permissible moment value in the axial direction when a single spline nut is used, as shown in the figure above. ** MA.2 indicates the permissible moment value in the axial direction when two spline nuts in close contact with each other are used, as shown in the figure above. For details on the maximum lengths of ball spline shafts by accuracy, please see A3

Open the catalog to page 10

L (Full length with seals) L2 ℓ0 L (Full length with seals) L2 φD 2- φ d0 through L1 (Full length without seals) L1 (Full length without seals) Spline shaft diameter Spline nut dimensions Outer diameter Keyway dimensions Greasing hole Model number coding L L1 (With seals) (Without seals) Symbol for clearance Accuracy Symbol for spline shaft (*4) in the rotational direction symbol (*3) (*2) Number of spline nuts Contamination protection on one shaft (no symbol for one nut) accessory symbol (*1) Overall spline shaft length (*5) (in mm) Download data by searching for the corresponding model...

Open the catalog to page 11All THK catalogs and technical brochures

-

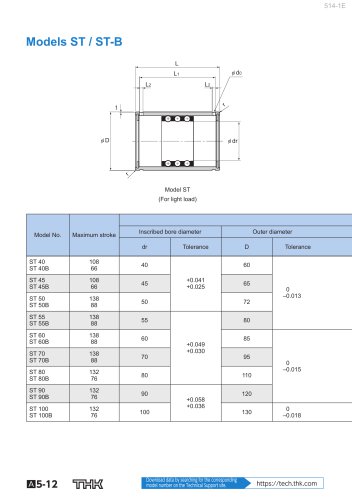

Models ST / ST-B

2 Pages

-

Predicting the Rigidity

5 Pages

-

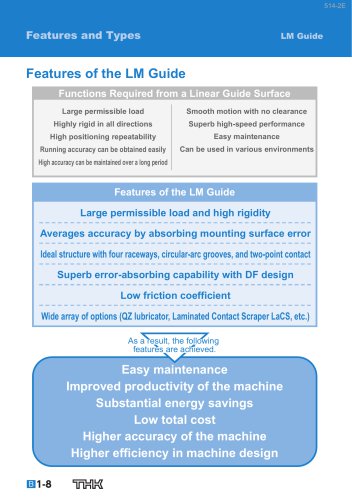

Features of the LM Guide

16 Pages

-

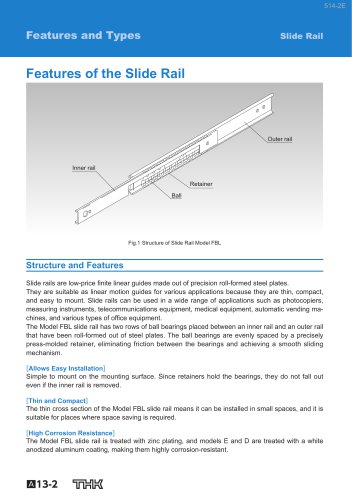

Features of the Slide Rail

1 Pages

-

PCT/PC

40 Pages

-

Models SHS-C and SHS-LC

2 Pages

-

Models SSR-XW and SSR-XWM

2 Pages

-

Models SSR-XV and SSR-XVM

2 Pages

-

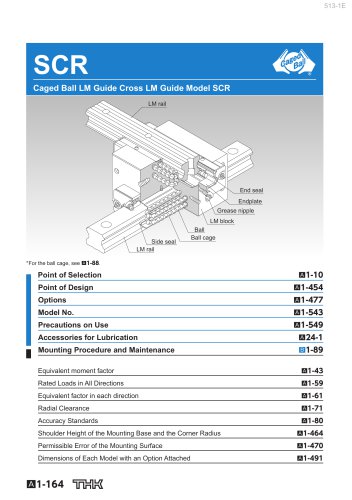

SCR

8 Pages

-

LM ACTUATOR GL

20 Pages

-

HDR

28 Pages

-

RSX

6 Pages

-

Fix Stages

4 Pages

-

Finite Stroke LM Guide EPF

12 Pages

-

LM ACTUATOR GL-N

28 Pages

-

LM Actuator TY

16 Pages

-

Clean-Room Actuator Model CSKR

20 Pages

Archived catalogs

-

Model SSR-XTB

2 Pages

-

Catalogue Caged Ball LM Guide

23 Pages

-

Low Price Actuator Model VLA

16 Pages

-

LM Guide Actuator Model KR

92 Pages

-

Ball Spline Series

24 Pages

-

Cross-Roller Ring Series

28 Pages

-

High-temparature LM Guide Series

28 Pages

-

Model HR Separate Type

20 Pages

-

LM Actuator Model TY

16 Pages

-

Guide Ball Bush LG

8 Pages

-

Limited-stroke LM Guide

12 Pages

-

LM Actuator Model GL-N

28 Pages

-

RoD Actuato

12 Pages

-

Product Ordering Guide

8 Pages

-

LM Guide Actuator KR

68 Pages