Catalog excerpts

Optimal for high speed and long stroke Long term maintenance-free operation is actualized Lightweight, compact structure For details, visit THK at www.thk.com ^Product information is updated regularly on the THK website. TOKYO. JAPAN

Open the catalog to page 1

This belt drive actuator has a caged ball LM Guide combined with a lightweight and compact aluminum base. Options such as a stainless steel cover, a motor bracket or a sensor make it useful for a variety of applications. 11. Optimal for long stroke high speed conveyance A maximum stroke of 4749 mm* is possible due to the belt drive method. A maximum travel speed of 3400 mm/s is possible when an AC servomotor (rated rotational speed 3000 min.-1) . * Stroke between the mechanical stoppers Maximum Travel Speed Note 1) Please note that when the stroke is short, it may not reach the maximum...

Open the catalog to page 2

2. Long service life and long term maintenance-free operation Built-in Caged Ball LM Guide model SHS. Long service life and long term maintenance-free operation are possible because there is no mutual friction between the balls and grease retention is improved due to the effect of the caged ball. QZ Lubricator is equipped as standard*. The QZ Lubricator supplies an optimal amount of lubricant to the raceway of the LM rail, substantially extending maintenance intervals. * For Model TY, the QZ Lubricator is equipped on a single side only for each LM block. ator Case Application & spreading QZ...

Open the catalog to page 3

Note 1) Positioning repeatability is standardized at an ambient temperature of 20°C. Note 2) Effective stroke is less than mechanical stroke for stainless steel cover option. Please refer to the dimensions tables for details (page 6). Note 3) The static permissible load is determined by either the bolt tightening strength or static rated load of the LM Guide unit. For the axial direction, it is determined by the torsional strength of pulley shaft. Note 4) Static permissible moment is the maximum value of the moment that can load on each direction. Note 5) Maximum load capacity guideline is...

Open the catalog to page 4

I Model Number Chart For concentric type reducer For orthogonal axis type reducer C: With a stainless steel cover

Open the catalog to page 5

Grease nipple /(Same position on the opposite side) Base length Input shaft Detailed View of E Detailed View of F ' When installing an orthogonal axis type reducer, please note that the input shaft will differ (see page 8). Note 1) Above figure shows the slider in mid-stroke. Note 2) Please contact THK for strokes other than those listed above. Note 3) Please install the unit using the T-slot (E section) on the side (see page 12).

Open the catalog to page 6

I Model TY20 (With stainless steel cover) /(Same position on the opposite side) Grease nipple Base length Input shaft Detailed View of E Detailed View of F ' When installing an orthogonal axis type reducer, please note that the input shaft will differ (see page 8). Note 1) Above figure shows the slider in mid-stroke. Note 2) Please use the actuator within effective strokes. Contact THK for strokes other than those listed above. Note 3) Please install the unit using the T-slot (E section) on the side (see page 12). Note 4) The maximum manufacturable base length is 3540 mm for stainless steel...

Open the catalog to page 7

Motor brackets for various reducers are available. Table of Supported Motor Bracket for Concentric Type Reducer Table of Supported Motor Bracket for Orthogonal Axis Type Reducer Note 1) The load inertial moment is bigger because this product uses the belt drive method. Using a reducer is recommended. Note 2) Please see Shimpo Drives, Inc.'s catalog for detailed reducer specifications. Note 3) The orthogonal axis type reducer is a special specification. Please contact THK for details. Note 4) If a reducer is installed by THK, please provide the motor manufacturer and model number of the motor.

Open the catalog to page 8

I Motor bracket dimensions Motor bracket for concentric type reducer Dimensions of Motor Bracket for Concentric Type Reducer unit: Motor bracket for orthogonal axis type reducer Dimensions of Motor Bracket for Orthogonal Axis Type Reducer unit: Note) Keys are not included in the reducer. Please have keys ready when installing the reducer.

Open the catalog to page 9

Concentric type reducer Orthogonal axis type reducer Dimensions When Mounting the Reducer

Open the catalog to page 10

I Dimensions of the reducer mounting section Dimensions of the Reducer Mounting Section unit: * Please select the dimensions according to the motor.

Open the catalog to page 11

Model TY can equip various sensors to the T-groove at the side of the base. When selecting a sensor, please specify using the corresponding code from the table below. Tables of Various Sensors Note 1) All sensor ouputs are NPN outputs. Note 2) N.O. contact point is a normally-open type; N.C. contact point is a normally-closed type. Note 3) Sensors are mounted on the product before being shipped. Please note that a photosensor connector is not included. I Sensor mounting dimensions * The direction of the sensor is changeable. The sensor can be removed by sliding the sensor mounting nut from...

Open the catalog to page 12

Base mounting bracket The mounting brackets for mounting the base are available. Note) this is not a standard attachment, so please specify the number of pieces required. 9 Base fixing bracket dimensions Example of base fixing bracket use (horizontal mount) 8.5 13 R7.5 12 M8 18.2 8.5 22.5 15 12 8 19.5 13 15 26 8 19.5 27 9 27 8.5 15 26 15 13 26 15 9 through 27 18.2 22.5 15 8 19.5 100 12 M8 Note 1) Mounting position must be horizontal. If a wall mounting position is used, please contact THK. Note 2) Mounting intervals of the base fixing brackets should be approximately 250 to 300 mm. 18.2 *...

Open the catalog to page 13

© Calculate the service life of the LM Guide from load conditions in order to check that It Is sufficiently safe and satisfies the desired service life. © Select the motor and check that the output torque of the reducer Is the same as permissible Input torque of the actuator or less. CÍ) Select the options (motor bracket, sensor, cover) as necessary. I Service life / static safety factor For Information about the service life and static safety factor of the TY model LM Guide, see the LM Guide section in the General Catalog. Also, rated life of the LM Guide can be calculated In the THK's...

Open the catalog to page 14All THK catalogs and technical brochures

-

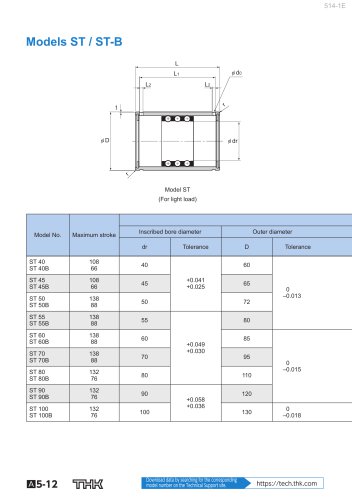

Models ST / ST-B

2 Pages

-

Predicting the Rigidity

5 Pages

-

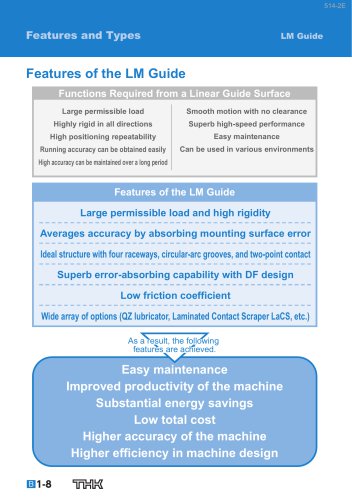

Features of the LM Guide

16 Pages

-

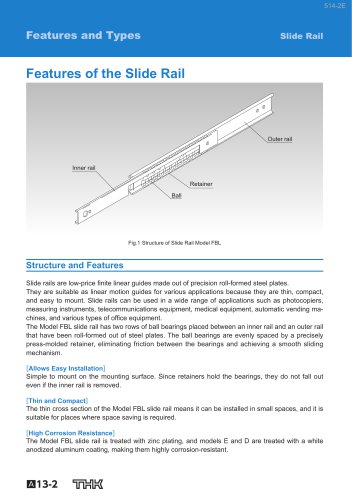

Features of the Slide Rail

1 Pages

-

PCT/PC

40 Pages

-

Models SHS-C and SHS-LC

2 Pages

-

Models SSR-XW and SSR-XWM

2 Pages

-

Models SSR-XV and SSR-XVM

2 Pages

-

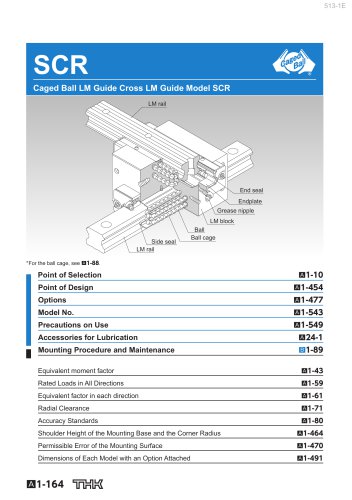

SCR

8 Pages

-

LM ACTUATOR GL

20 Pages

-

HDR

28 Pages

-

RSX

6 Pages

-

Fix Stages

4 Pages

-

Finite Stroke LM Guide EPF

12 Pages

-

LM ACTUATOR GL-N

28 Pages

-

LM Actuator TY

16 Pages

-

Clean-Room Actuator Model CSKR

20 Pages

Archived catalogs

-

Model SSR-XTB

2 Pages

-

Catalogue Caged Ball LM Guide

23 Pages

-

Low Price Actuator Model VLA

16 Pages

-

LM Guide Actuator Model KR

92 Pages

-

Ball Spline Series

24 Pages

-

Cross-Roller Ring Series

28 Pages

-

High-temparature LM Guide Series

28 Pages

-

Model HR Separate Type

20 Pages

-

Guide Ball Bush LG

8 Pages

-

Limited-stroke LM Guide

12 Pages

-

LM Actuator Model GL-N

28 Pages

-

RoD Actuato

12 Pages

-

Product Ordering Guide

8 Pages

-

LM Guide Actuator KR

68 Pages