Catalog excerpts

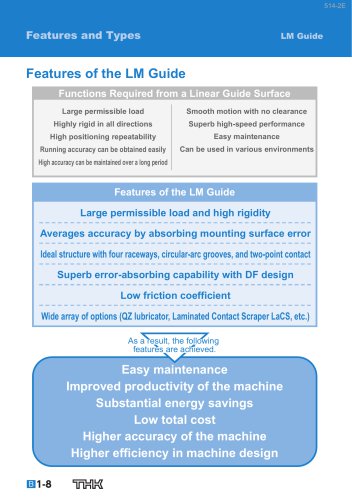

Features of the LM Guide Functions Required from a Linear Guide Surface Large permissible load Smooth motion with no clearance Highly rigid in all directions Superb high-speed performance High positioning repeatability Easy maintenance Running accuracy can be obtained easily Can be used in various environments High accuracy can be maintained over a long period Features of the LM Guide Large permissible load and high rigidity Averages accuracy by absorbing mounting surface error Ideal structure with four raceways, circular-arc grooves, and two-point contact Superb error-absorbing capability with DF design Low friction coefficient Wide array of options (QZ lubricator, Laminated Contact Scraper LaCS, etc.) As a result, the following features are achieved. Easy maintenance Improved productivity of the machine Substantial energy savings Low total cost Higher accuracy of the machine Higher efficiency in machine design B1-8

Open the catalog to page 1

Features and Types Features of the LM Guide Large Permissible Load and High Rigidity Linear bushing Mounting base 165 LM block 34 LM rail Linear Bushing Model LM80 OP Basic dynamic load rating: 14.7 kN Basic dynamic load rating: 7.35 kN Fig. 1: Comparison between the LM Guide and the Linear Bushing Table 1: Load Capacity per Ball (P and P1) Permissible contact surface pressure: 4,200 MPa Ball diameter Flat surface Fig. 2: Load Capacity per Ball Large Permissible Load The LM Guide has raceway grooves with a radius almost equal to the ball radius, which is a significant difference from...

Open the catalog to page 2

High Rigidity The LM Guide is capable of bearing vertical and horizontal loads. Additionally, due to the circular-arc groove design, it is capable of carrying a preload as necessary to increase its rigidity. When compared with a feed screw shaft system and a spindle in rigidity, the guide surface using an LM Guide has higher rigidity. Example of comparing static rigidity between the LM Guide, a feed screw shaft system and a spindle (vertical machining center with the main shaft motor of 7.5 kW) Table 2: Comparison of Static Rigidity Unit: N/m Components LM Guide: SVR45LC/C0 (C0...

Open the catalog to page 3

Features and Types Features of the LM Guide High Precision of Motion 10 20 30 Number of commands (pulse) Minimal Lost Motion The LM Guide is provided with an ideal rolling mechanism. Therefore, the dierence between dynamic and static friction is minimal and lost motion hardly occurs. 10 20 30 Number of commands (pulse) Square Slide + Turcite (Measurements are taken with the single-axis table loaded with a 500 kg weight) Fig. 4: Comparison of Lost Motion between an LM Guide and a Slide Guide Table 3: Lost Motion Comparison Test method Type LM Guide (HSR45) Square slide + turcite C1 clearance...

Open the catalog to page 4

High Running Accuracy Use of the LM Guide allows you to achieve high running accuracy. Measurement method 30 Fig. 5: Dynamic Accuracy of a Single-Axis Table

Open the catalog to page 5

Features and Types Features of the LM Guide High Accuracy Maintained over a Long Period The LM Guide employs an ideal rolling mechanism with negligible wear and high precision that is maintained over a long period of time. As shown in Fig. 6, when the LM Guide operates under both a preload and a normal load, more than 90% of the preload remains even after running 2,000 km. 800 Operating conditions Model No. : HSR65L Radial clearance : C0 (preload: 15.7 kN) Stroke : 1,050 mm Speed : 15 m/min (stops 5 sec at both ends) Acceleration/deceleration time in rapid motion : 300 ms (acceleration: =...

Open the catalog to page 6

Averages Accuracy by Absorbing Mounting Surface Error The LM Guide contains highly spherical balls and has a self-contained structure with no clearance. In addition, because several LM rails can be used in parallel to form a multiple-axis guide system, the LM Guide is capable of averaging and absorbing straightness, flatness, or parallelism errors that might occur in the machining of the base to which the LM Guide is to be mounted or in the installation of the LM Guide. The magnitude of the averaging eect varies according to the length or size of the misalignment, the preload applied on the...

Open the catalog to page 7

Features and Types Features of the LM Guide Even on a roughly milled mounting surface, the LM Guide drastically increases the running accuracy of the top face of the table. Installation Example When comparing the mounting surface accuracy (a) and the table running accuracy (b), the results are: Mounting surface Bottom surface Horizontal Side surface 105 m Bottom surface B 80 m Side surface D Side surface C Fig. 10: Surface Accuracy of the LM Guide Mounting Base (Milled Surface Only) Fig. 11: Running Accuracy After the LM Guide Is Mounted Table 5: Actual Measurement of Running Accuracy on...

Open the catalog to page 8

Easy Maintenance Unlike with sliding guides, the LM Guide does not incur uneven wear. As a result, sliding surfaces do not need to be reconditioned, and precision does not need to be altered. Regarding lubrication, sliding guides require forced circulation of a large amount of lubricant so as to maintain an oil film on the sliding surfaces, whereas the LM Guide only needs periodical replenishing of a small amount of grease or lubricant. This makes maintenance simple and also helps keep the work environment clean.

Open the catalog to page 9

Features and Types Features of the LM Guide Substantial Energy Savings As shown in Table 6, the LM Guide has a substantial energy saving effect. Table 6: Comparative Data on Sliding and Rolling Characteristics Machine specifications Single-axis surface grinding machine (sliding guide) Three-axis surface grinding machine (rolling guide) Overall length × overall width Total mass Table mass Grinding area Table guide Rolling through V-V guide Rolling through LM Guide installation No. of grinding stone axes Three axes (5.5 kW + 3.7 kW x 2) Grinding capacity: 3 times greater Table drive...

Open the catalog to page 10

Low Total Cost Compared with a sliding guide, the LM Guide is easier to assemble and does not require highly skilled technicians to perform the adjustment work. This reduces assembly labor and allows machines and systems incorporating the LM Guide to be produced at a lower cost. The figure below shows an example of the difference in the assembly procedures for machining centers that use sliding guides and those that use LM Guides. Normally, with a sliding guide, the surface on which the guide is installed must be ground to a very smooth finish. However, the LM Guide can offer high precision...

Open the catalog to page 11All THK catalogs and technical brochures

-

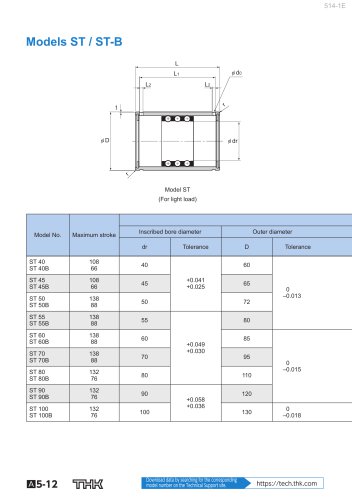

Models ST / ST-B

2 Pages

-

Predicting the Rigidity

5 Pages

-

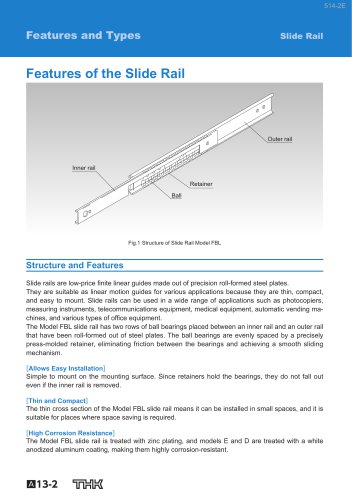

Features of the Slide Rail

1 Pages

-

PCT/PC

40 Pages

-

Models SHS-C and SHS-LC

2 Pages

-

Models SSR-XW and SSR-XWM

2 Pages

-

Models SSR-XV and SSR-XVM

2 Pages

-

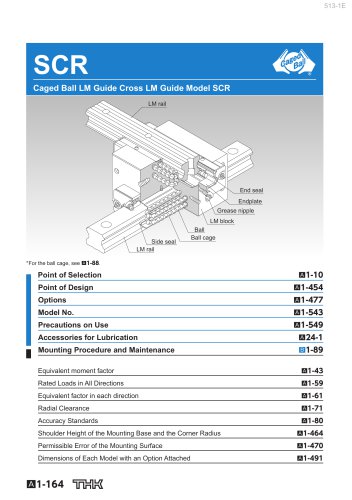

SCR

8 Pages

-

LM ACTUATOR GL

20 Pages

-

HDR

28 Pages

-

RSX

6 Pages

-

Fix Stages

4 Pages

-

Finite Stroke LM Guide EPF

12 Pages

-

LM ACTUATOR GL-N

28 Pages

-

LM Actuator TY

16 Pages

-

Clean-Room Actuator Model CSKR

20 Pages

Archived catalogs

-

Model SSR-XTB

2 Pages

-

Catalogue Caged Ball LM Guide

23 Pages

-

Low Price Actuator Model VLA

16 Pages

-

LM Guide Actuator Model KR

92 Pages

-

Ball Spline Series

24 Pages

-

Cross-Roller Ring Series

28 Pages

-

High-temparature LM Guide Series

28 Pages

-

Model HR Separate Type

20 Pages

-

LM Actuator Model TY

16 Pages

-

Guide Ball Bush LG

8 Pages

-

Limited-stroke LM Guide

12 Pages

-

LM Actuator Model GL-N

28 Pages

-

RoD Actuato

12 Pages

-

Product Ordering Guide

8 Pages

-

LM Guide Actuator KR

68 Pages