Catalog excerpts

Ball Spline Series_ Optimal for mechanisms that perform linear motion while transmitting a torque Capable of high-speed motion and high-speed rotation A wide array of lineups TOKYO. JAPAN CATALOG No.381-3E

Open the catalog to page 1

Ball Spline Series Medium-torque Type High-torque Type Rotary Type

Open the catalog to page 2

Ball Spline Series Seal Snap ring Spline shaft Spline nut Ball Ball Retainer Spline nut Snap ring Model LBS Seal Spline shaft Retainer Model LT Structure of Ball Spline Models LBS and LT Structure and Features The Ball Spline is an innovative linear motion system in which balls accommodated in the spline nut transmit torque while linearly moving on precision-ground raceways on the spline shaft. , Unlike the conventional structure, a single spline nut can provide a preload with THK s Ball Spline. As a result, the Ball Spline demonstrates high performance in environments subject to vibrations...

Open the catalog to page 3

^Classification of Ball Splines There are three types of the Ball Spline: medium-torque type, high-torque type and rotary type. You can choose a type according to the intended use. In addition, wide arrays of spline nut shapes are available for each type, enabling the user to choose a desired shape according to the mounting or service Shaft diameter Nominal shaft diameter: Nominal shaft diameter: Model LBST Nominal shaft diameter: Nominal shaft diameter: Nominal shaft diameter: Nominal shaft diameter: Model LTR-A Nominal shaft diameter: Model LBGT Nominal shaft diameter:

Open the catalog to page 4

QConditions and Guidelines for Selecting of a Preload Table 1 provides guidelines for selecting a clearance in the rotational direction with given conditions of The rotational clearance of the Ball Spline significantly affects the accuracy and rigidity of the spline nut. Therefore, it is essential to select a correct clearance according to the intended use. Generally, the Ball Spline is provided with a preload. When it is used in repeated circular motion or reciprocating straight motion, the Ball Spline is subject to a large vibration impact, and therefore, its service life and accuracy are...

Open the catalog to page 6

Table 2 Clearance in the Rotational Direction for Models LT and LF Table 3 Clearance in the Rotational Direction for Models LBS, LBF, LBST, LBR and LBH Table 4 Clearance in the Rotational Direction for Model LTR

Open the catalog to page 7

The accuracy of the Ball Spline is classified into three grades: normal grade (no symbol), high grade (H) and precision grade (P), according to the run-out of spline nut circumference in relation to the support of the spline shaft. Fig. 3 shows the measurement items. Part-mounting section Support section / Spline section \ Part-mounting section Support section Fig.3 Accuracy Measurement Items for the Ball Spline Table 5 Run-out of the Spline Nut Circumference in relation to the Support Section of the Spline Shaft Un( ^m Note 1 : The dimension in parentheses does not apply to a nominal shaft...

Open the catalog to page 8

Table 7 Concentricity of the Part-mounting Section in Relation to the Support Section of the Spline Shaft Table 8 Perpendicularity of the Spline Nut's Flange Mounting Surface to the Support Section of the Spline Shaft Note: Except models LBG, LBGT, LTR and LTR-A Maximum Manufacturing Length by Accuracy Tables 9 and 10 show the maximum manufacturing lengths of the ball spline shafts by accuracy. Table 9 Maximum Manufacturing Length of Models Table 10 Maximum Manufacturing Length of Models The lengths in the table each represent the overall shaft length. For the standard hollow shaft type...

Open the catalog to page 9

Dimensional Table for Model LT Note 1 : Models LT4 and 5 do not use a retainer. Do not remove the shaft from the spline nut (doing so will cause balls to fall off). Note 2: O: For those models, high-temperature types (metal retainer, service temperature: up to 100°C) are available. "L"-Symbol for high-temperature type Example of model number coding Accuracy symbol Overall spline shaft Dust prevention accessory symbol No symbol: without seal UU: rubber seal attached on both ends of spline nut U: rubber seal attached on either end of spline nut Symbol for standard hollow spline shaft (no...

Open the catalog to page 10

Note 3: MM indicates the permissible moment value in the axial direction when one spline nut is used. MA2 indicates the permissible moment value in the axial direction when two spline nuts are used. (Using a single LT unit is not stable in accuracy. We recommend using two units in close contact with each other.) Note 4: For details on the maximum lengths of ball spline shafts by accuracy, please see page 8.

Open the catalog to page 11

Dimensional Table for Model LF 4-^di drilled through, ¡j>d2 counter bore depth h 4-^di drilled through, ¡j>d2counter bore depth h Note 1: 0:For those models, high-temperature types (metal retainer, service temperature: up to 100°C) are available. ~£-Symbol for high-temperature type Example of model number coding Accuracy symbol Overall spline shaft Dust prevention accessory symbol No symbol: without seal UU: rubber seal attached on both ends of spline nut U: rubber seal attached on either end of spline nut Symbol for standard hollow spline shaft (no symbol: solid spline shaft)

Open the catalog to page 12

Note 2: MM indicates the permissible moment value in the axial direction when one spline nut is used. MA2 indicates the permissible moment value in the axial direction when two spline nuts are used. (Using a single LF unit is not stable in accuracy. We recommend using two units in close contact with each other.) Note 3: For details on the maximum lengths of ball spline shafts by accuracy, please see page 8.

Open the catalog to page 13

Dimensional Table for Model LBS - Medium Load Type (Overall length with seal) (Overall length without seal) Note 1 : Models LBS6 and 8 are end cap types. With models LBS6 and 8, do not give a shock to the end cap. Note 2: A high-temperature type is not available for miniature Ball Splines. O: For those models, high-temperature types (metal retainer, service temperature: up to 100°C) are available. "E-Symbol for high-temperature type 9: Those models can be attached with a felt seal. Ball Splines using metal retainers cannot be attached with a felt seal.

Open the catalog to page 14All THK catalogs and technical brochures

-

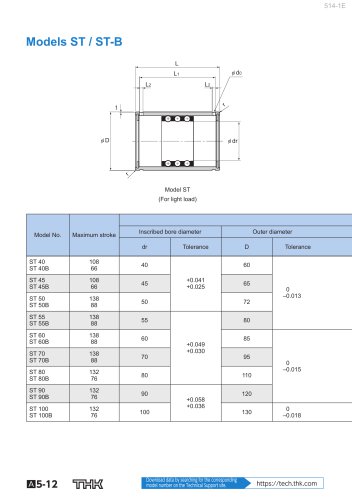

Models ST / ST-B

2 Pages

-

Predicting the Rigidity

5 Pages

-

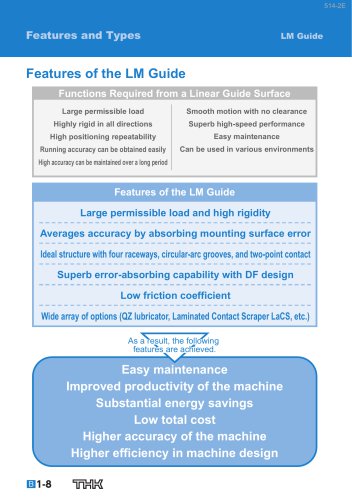

Features of the LM Guide

16 Pages

-

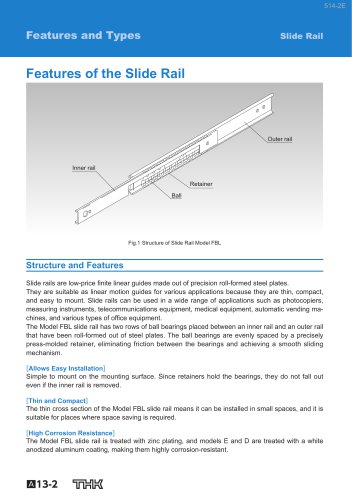

Features of the Slide Rail

1 Pages

-

PCT/PC

40 Pages

-

Models SHS-C and SHS-LC

2 Pages

-

Models SSR-XW and SSR-XWM

2 Pages

-

Models SSR-XV and SSR-XVM

2 Pages

-

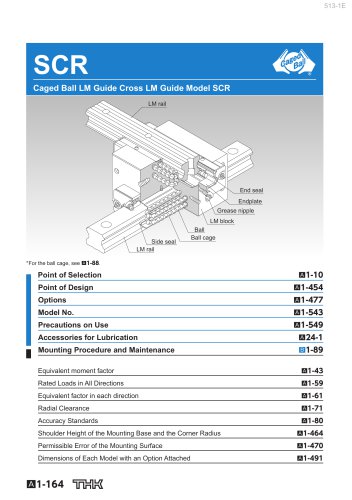

SCR

8 Pages

-

LM ACTUATOR GL

20 Pages

-

HDR

28 Pages

-

RSX

6 Pages

-

Fix Stages

4 Pages

-

Finite Stroke LM Guide EPF

12 Pages

-

LM ACTUATOR GL-N

28 Pages

-

LM Actuator TY

16 Pages

-

Clean-Room Actuator Model CSKR

20 Pages

Archived catalogs

-

Model SSR-XTB

2 Pages

-

Catalogue Caged Ball LM Guide

23 Pages

-

Low Price Actuator Model VLA

16 Pages

-

LM Guide Actuator Model KR

92 Pages

-

Cross-Roller Ring Series

28 Pages

-

High-temparature LM Guide Series

28 Pages

-

Model HR Separate Type

20 Pages

-

LM Actuator Model TY

16 Pages

-

Guide Ball Bush LG

8 Pages

-

Limited-stroke LM Guide

12 Pages

-

LM Actuator Model GL-N

28 Pages

-

RoD Actuato

12 Pages

-

Product Ordering Guide

8 Pages

-

LM Guide Actuator KR

68 Pages