Website:

Thames Side Sensors

Website:

Thames Side Sensors

Group: Tecnicas

Catalog excerpts

T85 SHEAR BEAM LOAD CELL FOR INDUSTRIAL WEIGHING capacities 300kg - 10,000kg This stainless steel shear beam load cell is available with approval according to OIML R60 Class C3 (3000 divisions) and is calibrated in mV/V/Ω by output current matching, which minimises corner correction time on multi-cell systems. The T85 is fully welded and hermetically sealed to IP68 and IP69K as standard. It can therefore be used in the harshest industrial environments and it’s typically used in weigh platforms, tank and vessel weighing, big bag (FIBC) filling systems, conveyors and machinery using weighing as part of its function. Capacities range from 300kg to 10,000kg. The Polyurethane cable provides excellent protection against chemicals, UV radiation, rodents and damage from cuts/impacts. ATEX approval for all Gas and Dust zones is available as an option. The certification for dust zones 20, 21 and 22 does not require safety barriers, which creates a large cost saving. For applications in aggressive environments where stress corrosion or acid attack could be a problem, the T85 can be supplied with an optional Parylene coating. For high temperature applications, an optional version of the T85 is available for operation in environments up to 150°C (continuous temperature). ■ Stainless steel construction ■ 3000 divisions (Class C3) OIML R60 approval ■ Calibrated in mV/V/Ω ■ Optional load feet and mounting accessories up to 5,000kg: patented LeverMount® and LA85 anti-vibration mount ■ Options of approval, Parylene coating and high temperature version ■ High integrity stainless steel cable entry ■ Wide operating temperature range ■ 5 Year Warranty ■ Industry standard dimensions and specifications

Open the catalog to page 1

more information... ATEX Certification For applications in hazardous or explosive environments, the T85 load cell has a number of ATEX certification options. The ‘ta’ mode of protection allows for use without safety barriers, which results in significant cost savings. Code Temperature Class Gas Zones 0, 1, 2 with safety barriers Dust Zones 20, 21, 22 without safety barriers Option: Parylene coating For applications in aggressive environments where stress corrosion or acid attack could be a problem, the stainless steel T85 load cell can be supplied with a special option of Parylene coating...

Open the catalog to page 2

more information... T85 Capacity range 7,500 - 10,000kg T85 MOUNTING ACCESSORIES Unique, patented LeverMount® accessory ■ Stainless steel grade 316 accessory Fast load cell installation/removal without jacking or dummy/false cells, even while vessel is full Production does not need to stop in event of changing a load cell Stable 3-point base mounting with no need for shims Substantial anti-lift protection Available up to 5 tonnes, in 3 sizes, according to the load cell capacity For applications with mixing and/or vibration Stainless steel and rubber construction Separately available...

Open the catalog to page 3

technical specification... T85 Load Cell Load Cell Capacity (E max) Load cell specification Combined Error Temperature Effect on Zero Balance Temperature Effect on Span Compensated Temperature Range Operating Temperature Range Safe Load Limit (E lim) Ultimate Overload Accuracy Class according to OIML R60: number of verification intervals (n) Minimum load cell verification interval (vmin) = E max / Y Creep (30 minutes) Zero Balance - ve Excitation BLUE - ve Signal YELLOW SCREEN Electrical Connections Via 4 core, 5.7mm diameter, screened polyurethane cable Screen not connected electrically to...

Open the catalog to page 4All Thames Side Sensors catalogs and technical brochures

-

VC3500 Load cell Data sheet

4 Pages

-

T85-T Load cell Data sheet

2 Pages

-

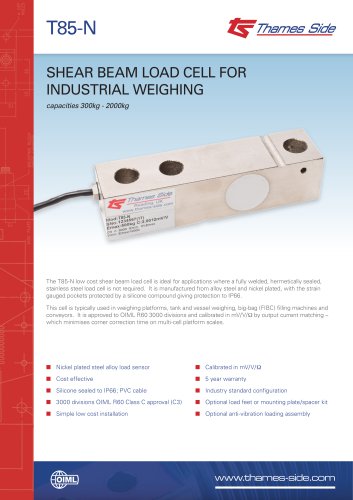

T85-N Load cell Data sheet

2 Pages

-

T95 Load cell Data sheet

2 Pages

-

T68 Load cell Data sheet

2 Pages

-

T66 Load cell Data sheet

2 Pages

-

T65 Load cell Data sheet

2 Pages

-

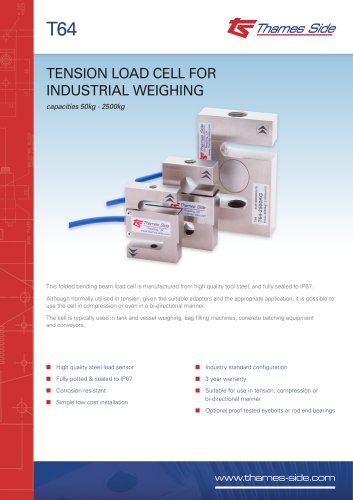

T64 Load cell Data sheet

2 Pages

-

T61 Load cell Data sheet

2 Pages

-

T60 Load cell Data sheet

2 Pages

-

T38 Load cell Data sheet

2 Pages

-

T35D load cell data sheet

2 Pages

-

T34D Load cell Data sheet

2 Pages

-

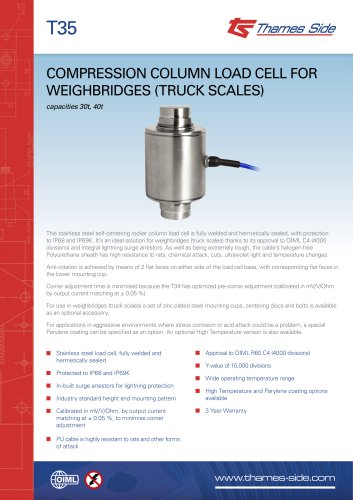

T35 Load cell Data sheet

2 Pages

-

T30 Load cell Data sheet

2 Pages

-

T20 Load cell Data sheet

2 Pages

-

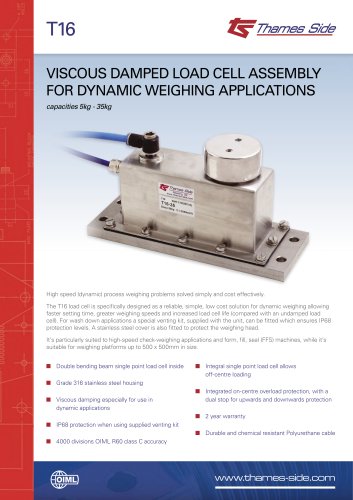

T16 Load cell Data sheet

2 Pages

-

T12A Load cell Data sheet

2 Pages

-

T12 Load cell Data sheet

2 Pages

-

T6 Load cell Data sheet

2 Pages

-

T5 Load cell Data sheet

2 Pages

-

T4 Load cell Data sheet

2 Pages

-

T2 Load Cell Datasheet

2 Pages

-

650 Load Cell Data Sheet

2 Pages

-

T11 Load Cell

2 Pages

-

LA66 Weighing Assembly

2 Pages