Website:

Thames Side Sensors

Website:

Thames Side Sensors

Group: Tecnicas

Catalog excerpts

ANTI-VIBRATION WEIGHING ASSEMBLY FOR HARSH ENVIRONMENTS capacities 300 - 10,000kg Ideal for applications with mixing, agitation and vibration, this stainless steel assembly is designed to reduce the vibration transmitted to the load cell. It is typically used in weighing platforms, big bag (FIBC) filling, belt weighers and hopper/tank weighing in the Food Processing, Chemical, Pharmaceutical and Bulk Handling industries. The stainless steel, OIML C3 approved, model T85 load cell used in this anti-vibration weighing assembly is fully welded and hermetically sealed for protection to IP68 and IP69K, allowing it to be used in extremely harsh environments. The complete assembly consists of a load cell, mounting stud, baseplate with spacer and stainless steel/elastomeric anti-vibration disc. ATEX certification, for both gas and dust zones, is available for the T85 load cell. To reduce costs, certification for use in dust zones 20, 21 and 22 without safety barriers is available. For applications in aggressive environments where stress corrosion or acid attack is an issue, a special Parylene coating for the load cell can be specified as an option. Other options are custom load cell cable lengths for volume OEM customers and a version for high temperature use. ■ Stainless steel load cell & mounting accessory ■ Hermetically sealed, fully welded construction ■ High Integrity cable entry ■ Simple, fast installation ■ High durability polyurethane load cell cable ■ Load cell options of approval, Parylene coating or high temperature version ■ 3000 divisions OIML R60 Class C (C3)

Open the catalog to page 1

technical specification... DO NOT FULLY TIGHTEN (SPRING WASHER FITTED) TANK/SILO PLATE SPACER WASHER T85 Load Cell ATEX Certification Code Temperature Class Gas Zones 0, 1, 2 with safety barriers Dust Zones 20, 21, 22 without safety barriers T85 Load Cell Load cell specification Combined Error Load Cell Capacity (E max ) Rated Output (S n ) Accuracy Class according to OIML R60: number of verification intervals (n) Minimum load cell verification interval (vmin ) = E max / Y *Pre-corner adjustment optimised at ± 0.05% by output current calibration Wiring diagram (using T85 load cell) + ve...

Open the catalog to page 2All Thames Side Sensors catalogs and technical brochures

-

VC3500 Load cell Data sheet

4 Pages

-

T85-T Load cell Data sheet

2 Pages

-

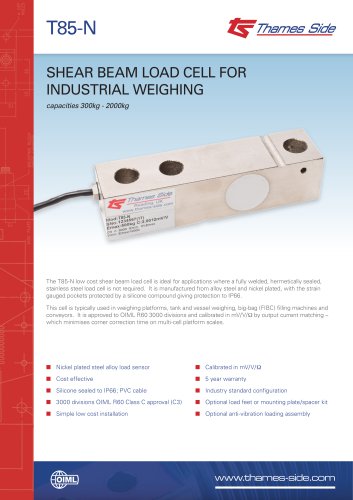

T85-N Load cell Data sheet

2 Pages

-

T85 Load cell Data sheet

4 Pages

-

T95 Load cell Data sheet

2 Pages

-

T68 Load cell Data sheet

2 Pages

-

T66 Load cell Data sheet

2 Pages

-

T65 Load cell Data sheet

2 Pages

-

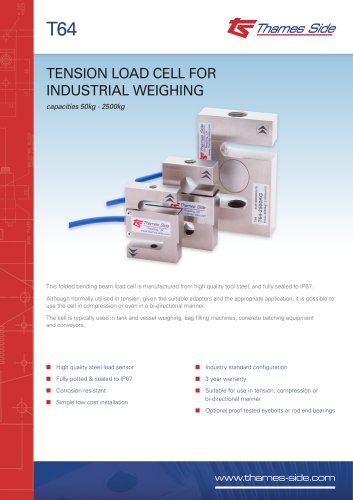

T64 Load cell Data sheet

2 Pages

-

T61 Load cell Data sheet

2 Pages

-

T60 Load cell Data sheet

2 Pages

-

T38 Load cell Data sheet

2 Pages

-

T35D load cell data sheet

2 Pages

-

T34D Load cell Data sheet

2 Pages

-

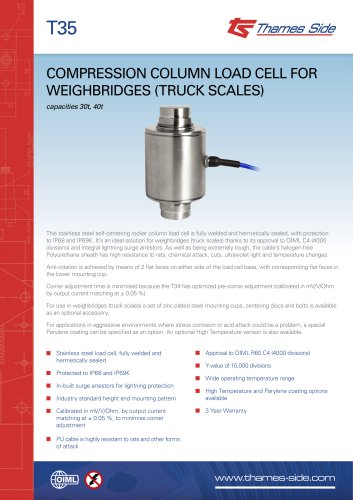

T35 Load cell Data sheet

2 Pages

-

T30 Load cell Data sheet

2 Pages

-

T20 Load cell Data sheet

2 Pages

-

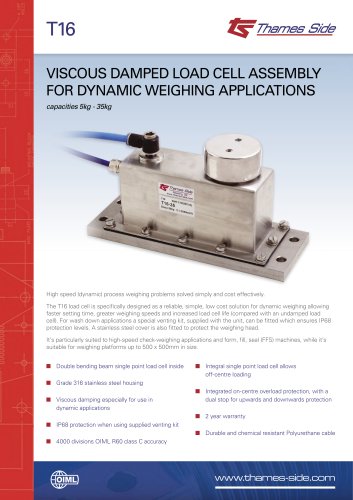

T16 Load cell Data sheet

2 Pages

-

T12A Load cell Data sheet

2 Pages

-

T12 Load cell Data sheet

2 Pages

-

T6 Load cell Data sheet

2 Pages

-

T5 Load cell Data sheet

2 Pages

-

T4 Load cell Data sheet

2 Pages

-

T2 Load Cell Datasheet

2 Pages

-

650 Load Cell Data Sheet

2 Pages

-

T11 Load Cell

2 Pages

-

LA66 Weighing Assembly

2 Pages