Catalog excerpts

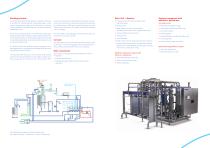

Tetra Albrix Continuous sugar-dissolving unit Future-proof efficiency Welcome to future-proof efficiency in sugar dissolving with the newest generation of our Tetra Albrix. The new design maximizes output and delivers huge savings – cutting heating energy costs by 42%, cooling energy costs by 55%, and CO2 emissions by 62%. Raw material costs are also greatly reduced thanks to higher accuracy. • Higher operational efficiency – cuts heating energy • Perfect fit in our complete customized line solutions Tetra Albrix is a dissolving unit for continous dissolving and pasteurisation of granulated sugar with a concentration of up to 67 °Brix. • New cross-flow filter for more efficient dissolving, lower costs by 42%, cooling energy costs by 55%, CO2 emissions by 62%, and raw material costs thanks to greater accuracy • Uncompromising food safety and quality • Future-proof flexibility with unique modular design energy consumption, and lower raw material costs • Advanced °Brix set-point control for exact dosing and huge cuts in energy and raw material costs • Continuous automatic control minimizes manual handling and cuts operator costs

Open the catalog to page 1

Working principle Incoming treated water is preheated in a separate water heater and fed into a dissolving tank. Granulated sugar is continously conveyed from hopper to dissolving tank. In order to maintain agitation in the dissolving tank, a pump circulates the sugar/water slurry. The slurry is pumped through a cross-flow filter, which separates dissolved sugar from sugar crystals. Sugar crystals return to the dissolving tank, while dissolved sugar passes through to an optional pasteurizer, optional decolourizing system, and to a final destination tank. An optional pasteurizer reduces...

Open the catalog to page 2

Additional equipment required with dissolver + pasteurizer + control of decolorizer Mass flow meter • Mass flow meters instead of magnetic flow meters on incoming water • When using reverse osmosis water or sweet water is recovered, this option is mandatory • Two bag filters, 25 micron • Shut off valves Pressure supervision on filters • Pressure transmitter with alarm Tower water cooling Ethernet communication • Extra section in the PHE + valves (included in the third model – dissolver + pasteurizer + control of decolorizer) • With supervisory automation system Control room solution Other...

Open the catalog to page 3All Tetra Pak catalogs and technical brochures

-

Brining system S

2 Pages

-

Mould Handling system

2 Pages

-

Ice Cream Filler A3

6 Pages

-

Ice Cream Mix unit A3

3 Pages

-

Ice Cream Mix unit A2

3 Pages

-

Powder Valve

2 Pages

-

Powder hopper

2 Pages

-

Tetra Pak® High Shear Mixer

2 Pages

-

Tetra Pak® Heat Exchangers

8 Pages

-

Tetra-laval-2017-2018

60 Pages

-

Tetralaval

60 Pages

-

Tetra Pak® Aseptic Tank VC

2 Pages

-

Tetra Pak® Aseptic Tank VD

2 Pages

-

Tetra Pak® In-line Blender D

2 Pages

-

Tetra Alblend™

5 Pages

-

Tetra Alblend 5SP

4 Pages

-

Tetra Alblend® carboblender

3 Pages

-

Tetra Alfast®B4

2 Pages

-

Mixing technology

28 Pages

-

Tetra Pak® Mixer RJCI

4 Pages

-

Tetra Alwin® Soy

2 Pages

-

The value of adding value

12 Pages

-

Tetra Magna Evaporator ? TVR

2 Pages

-

Tetra Magna Evaporator ? MVR

2 Pages

-

Tetra Alsafe® Aseptic tank

2 Pages

-

Moving Food Forward. Together?

24 Pages

-

Tetra Alex® 2

2 Pages

-

HighHygieneTank

2 Pages

-

Tetra Therm® Aseptic Drink 1

3 Pages

-

Tetra Hoyer DeepBlue?SM

4 Pages