Website:

Testing Machines Inc

Website:

Testing Machines Inc

Group: TMI Group

Catalog excerpts

CTT CONSTANT TENSION TRANSPORT TOTAL CONCEPT FOR SPUN YARN TESTING with Five Configurations • Weak Spot Detection (CTT-BU) • Lint Generation Tester (CTT-Lint) • Yarn Abrasion Tester (CTT-YAT) • Dynamic Tension Tester-Friction Tester (CTT-DTT) shown above • Stick-Slip Test HIGH-SPEED DYNAMIC TEST INSTRUMENT for Spinners, Weavers, Knitters and Fiber Producers !! The CTT is a versatile dynamic test instrument that is available as a mini textile laboratory. With its easy to change test attachments, the CTT is the only lab instrument that offers more than 10 yarn tests on the same instrument. This versatility along with its dynamic test principle, the CTT offers every fiber and yarn user the ability to eliminate the high cost of running trials on production instrument. OPERATION: Applies and maintains tension between 2-700g at test speeds 20-360m/min This provides variety of production trial conditions to check yarn performance beforehand. VERSATILITY: With interchangeable test attachments, the CTT is the only lab instrument that offers more than 10 yarn tests on the same instrument. Its unique design provides the ability to test natural and synthetic yarns as well as high performance and technical yarns, including carbon, glass or hybrid yarns, which cannot be tested with conventional capacitive based systems. DYNAMIC TEST: CTT dynamic test principle allows every section of the yarn to be tested under constant tension and speed conditions. This provides the closest conditions to the actual production that the yarn has to experience. END-USERS: All types of Natural and Synthetic yarn producers and buyers, including cotton yarn, Polyester yarns, Nylon yarns, the blend yarns, flax and jute yarns, elastomeric covered yarns, wool and acrylic yarns, rayon and viscose yarns, silk yarns, carbon and carbon-glass hybrid yarns, and many others.

Open the catalog to page 1

Constant Tension Transport Dynamic • Versatile • Quick Results CTT-Dynamic Tensile and Weak Spot Tester In this test, each yarn is tested for a set length at pre-determined tension up to 700g and speed condition as high as 360m/min. Since a yarn is only as strong as the its “weakest” spots, testing yarn strength dynamically is the best way to predict its performance. The CTT can scan every millimeter of the yarn up to 21km per hour. CTT-Dynamic Tension Tester (CTT-DTT) By applying constant input tension and monitoring the output tension on the yarn, CTT Tension Test measures the tension...

Open the catalog to page 2

Constant Tension Transport CTT-YAT (Yarn Abrasion Tester) The CTT Abrasion test measures the abrasiveness of the yarn while it is running under constant tension at test speeds up to 360m/min. The yarn abrasiveness can be affected most notably by the fiber shape and the amount of the TiO² on the yarn. If the yarn is really abrasive, the result will be frequent changes of the machine parts such as needles, yarn guides, which in return will increase spare part consumption and overall manufacturing cost. In this test, the yarn will be running over a standard abrasion wire. When the wire breaks,...

Open the catalog to page 3

CTT TECHNICAL DATA Types of Yarn Cotton yarn, Polyester yarns, Nylon yarns, the blend yarns, flax and jute yarns, elastomeric covered yarns, wool and acrylic yarns, rayon and viscose yarns, silk yarns, carbon and carbon-glass hybrid yarns, etc. Four Tension Ranges Sensitive Range 0.5-10 grams, ± 0.1g Low Range 2-100 grams, ± 0.2g Middle Range 10-300 grams, ± 1g High Range 20-700 grams, ± 2g Speed Ranges 20-360 meters/min, Slow test options (1 cm/min, 4 cm/min, 0.2 m/min, 1 m/min) Available for stick-slip test ASTM Standards Pin Friction test- D3108 Standard test method for COF, Yarn to...

Open the catalog to page 4All Testing Machines Inc catalogs and technical brochures

-

13-60 Burst Testers

2 Pages

-

43-02 Monitor Impact Tester

2 Pages

-

Top Load Compression Tester

2 Pages

-

17-76 Compression Tester

2 Pages

-

10-48 Rotary Abraser

2 Pages

-

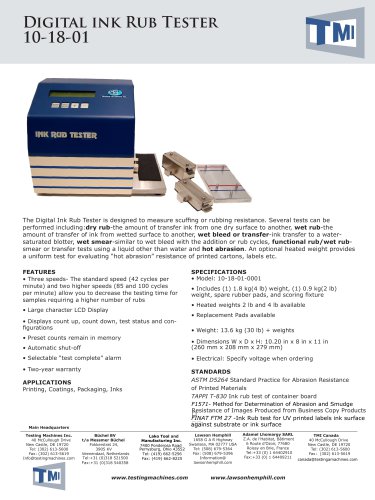

Digital Ink Rub Tester

1 Pages

-

49-56 Digital Micrometer

2 Pages

-

49-86 Digital Micrometer

2 Pages

-

49-87 Digital Micrometer

2 Pages

-

Portable Sword Hygrometer

1 Pages

-

58-03 Densometers

1 Pages

-

GraphMaster

2 Pages

-

SD-200L

2 Pages

-

tear-tester

2 Pages

-

13-50 Puncture Tester

1 Pages

-

Dial Micrometers

2 Pages

-

13-50 Puncture Tester

1 Pages

-

13-12 Pneumatic Burst Tester

1 Pages

-

68-21 Digital Hazemeter

2 Pages

-

92-15 Laray Viscometer

1 Pages

-

21-09 Automatic Densimeter

1 Pages

-

56-15 Electric Incinerator

1 Pages

-

Cobb Sizing Testers

1 Pages

-

Tensile Tester

3 Pages

-

Impact Tester

2 Pages

-

compression testing machine

3 Pages

-

Bekk Smoothness Tester

2 Pages

-

Dynamic Modulus Tester

2 Pages

-

ADF Yarn Strength Tester

4 Pages

-

LabMaster Slip Friction

2 Pages

-

Ink Rub tester

1 Pages

-

49-50 Digital Micrometer

2 Pages

-

Heat Sealer

4 Pages

-

Slip Friction tester

2 Pages

-

Brightnesss Color Meter

4 Pages

-

TS-4 Heat Sealer

3 Pages

-

Hygrometer

1 Pages

-

Moisture Meter

2 Pages

-

Photovolt

2 Pages

-

Bending Resistance

1 Pages

-

Internal Bond tester

4 Pages

-

Loop Tack tester

2 Pages

-

Probe Tack

2 Pages

-

Short Span Compression

1 Pages

-

Peel/Adhesion Tester

2 Pages

-

Dart Impact Tester

1 Pages

-

Canadian Freeness

1 Pages

-

Pulp Beater

1 Pages

-

Standard Sheet Former

1 Pages

-

Tear Tester

1 Pages

-

TS-12 Heat Sealer

2 Pages

-

49-60 Digital Micrometer

1 Pages

-

portable hardness tester

1 Pages