Website:

TesT GmbH

Website:

TesT GmbH

Catalog excerpts

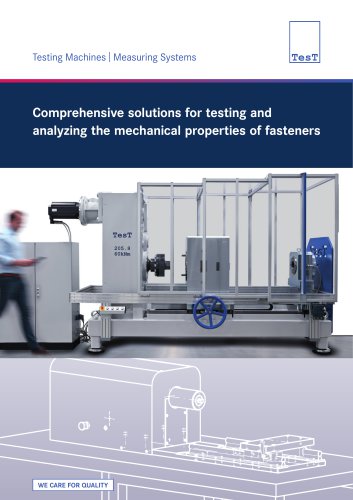

Testing Machines | Measuring Systems Comprehensive solutions for testing and analyzing the mechanical properties of fasteners

Open the catalog to page 1

Coefficient of friction testing machines Preparation of a friction coefficient determination Quality is no coincidence TesT offers integrated solutions for testing of bolts, nuts, washers and locking elements, made in Germany. Our coefficient of friction test benches, equipped with our patented multi-component sensors, have conquered the world. Our testing devices meet all national and international standards and can be adapted to any company’s specific requirements. The measured and evaluated forces, torques and angles allow for the determination of friction coefficients for screws, bolts,...

Open the catalog to page 2

Friction coefficient test rig model 205.4 with 201.1 Friction coefficient test rig model 205.7 with 201.7 Multi-component sensors Measuring range table of TesT sensors The patented multi-component sensors enable the effective decoupling of stresses within bolted joints resulting from clamping force and torque. This well-established measuring principle, which has been further developed over many years, enables precise measurement of the clamping force, the total torque and the partial torques within only one robust sensor. Additionally, the angle is measured within the machine with high...

Open the catalog to page 3

Vibration testing machines for bolted joints Flexibility in control and evaluation The preload-time diagram determined in the process diagram, along with the number of cycles, provides corresponding information about the loosening behavior of the bolted joint under dynamic lateral load. In conjunction with our TesTWinner® 950 software, our customers receive optimal efficiency and flexibility as well as a direct statement about the loosening angle, preload force, lateral force and lateral displacement amplitude. Optionally, the tightening torque can also be recorded at the start of the test....

Open the catalog to page 4

Complete setup of a TesT vibration testing machine Technical versions of the TesT vibration testing machines Model Measurement of lateral force Transverse displacement amplitude Control of lateral displacement amplitude during the test Measurement of the release angle (option) Motorized controlled tightening (option) Other configurations available on request

Open the catalog to page 5

Measurement and control electronics The convenient testing software At the heart of all TesT testing machines lies the integration of TesTController 850 for measurement and control electronics, combined with the TesTWinner® 950 application software. This pairing creates a versatile and highly flexible system capable of managing everything from test requirements to generating detailed test reports. TesTWinner® 950 enables the convenient management and combination of a wide variety of processes, their display and evaluation. TesT Controller The TesTWinner® 950 software package is designed to...

Open the catalog to page 6

Calibration service The traceable calibration of testing machines and measuring devices is essential for industrial quality controls. Calibration certificates are a mandatory proof of test equipment monitoring for ISO 9001 and ISO 17025 standards. Reliable long-term service Know-how directly from the manufacturer Individual maintenance interval Helpful tips for machine users Calibration intervals depend on the applicable standard, but generally should not exceed 12 months. Special considerations apply for changes of location or after repairs. The first machine we developed over 25 years ago...

Open the catalog to page 7

Universal testing machines Torsion testing machines Coefficient of friction testing machines Vibration testing machines Calibration machines (direct loading with masses and electromechanical machines) Force and torque sensors Force gauges and test frames Weighing technology DAkkS-Calibration laboratory Our modular system, modern measurement and control electronics and flexible software provide extensive options for configuring suitable testing machines. Contact us and tell us about your testing task. We will be happy to make our contribution to your future-oriented testing machine. TesT...

Open the catalog to page 8All TesT GmbH catalogs and technical brochures

-

Crane Scales – Model 651

2 Pages

-

Modell 1001 / 1011 / 1021

1 Pages

-

Model 341

2 Pages

-

Model 342

2 Pages

-

Model 343

2 Pages

-

Model 344

2 Pages

-

Model 347

2 Pages

-

Accessories

4 Pages

-

Dynamometer – Model 323

2 Pages

-

Modell 1101 / 1111 / 1121

1 Pages

-

Torsion Testing Machines

4 Pages

-

451

2 Pages

-

651

2 Pages

-

340

2 Pages

-

Dynamometers

1 Pages

-

Universal Testing Machines

8 Pages

-

USB Contoller - Model 850

1 Pages

-

Software - SoftTesT

1 Pages

-

ForceGauges + LoadFrames

8 Pages