Website:

TEMPSENS

Website:

TEMPSENS

Group: Pyrotech

Catalog excerpts

Thermal & Cable Solutions

Open the catalog to page 1

IMPORTANCE OF TEMPERATURE PROFILING The majority of furnaces use thermocouples that measure the ambient temperature; hence, it's common to have multiple thermocouples detecting temperatures at a single place inside a furnace, but they are far from the product. PROBLEMS ASSOCIATED WITH CONVENTIONAL METHOD A trailing thermocouple that has been attached to a product and placed inside a furnace has traditionally been used to measure product temperatures. The usefulness of the information recorded is impacted by the process temperatures because trailing thermocouples are expensive and difficult...

Open the catalog to page 2

SMARTRACK 10 DATALOGGER Power ON/OFF Led Indication. Power ON/OFF and datalogging button. Battery charge or discharge Led Indication USB communication socket and charging socket. Thermocouple sockets. TECHNICAL SPECIFICATIONS Specifications Thermocouple Type Reference Junction Compensation Memory Size 50000 readings per channel with date & Time Sample Interval Rechargeable : NiMH (3 nos, AA size) Non-Rechargeable : Lithium (3 nos, AA size) Type selection, No. of channel selection, Sampling interval, Date and time setting etc. Charging, low Battery, Communication, Start, Stop etc.

Open the catalog to page 3

SMARTLOG SOFTWARE Smartlog software helps not only to collect data but also process. For better analysis a variety of functions are transforms it to information. This information allows you provided where user can change the parameters to analyze your data efficiently and optimize your according to their need. l Compare data of multiple runs. l Export & Import data in excel format. l Multiple triggering modes. l In-Built product manuals.

Open the catalog to page 4

Thermal Duration Heat Sinks Maximum Temperature In re-flow ovens is small oven opening to monitor soldering and other processes. In circuit board assembly, Where mass component are soldered together. *High temperature can also be achieved on expense of less duration. for further information contact us. Thermal Duration Dimensions(L x W x H) (mm) Heat Sinks The barrier includes phase change material based heat sinks. for better performance please keep the heat sink inside refrigerators i.e. below 15°C. Maximum Temperature Automotive component supply; Powder coat/General paint OEM...

Open the catalog to page 5

Thermal Duration Heat Sinks The barrier includes phase change material based heat sinks. for better performance please keep the heat sink inside refrigerators i.e. below 15°C. Maximum Temperature Aluminium aging, low temperature cure, automotive paint cure line. High temperature coating cure application like PTFE and dacromet. Thermal Duration Heat Sinks The barrier includes phase change material based heat sinks. for better performance please keep the heat sink inside refrigerators i.e. below 15°C. Maximum Temperature Vaccum annealing furnaces with air quenching. High temperature annealing...

Open the catalog to page 6

Thermal Duration Heat Sinks Here water stored in a tank acts as a phase change material. Maximum Temperature In the mass production of Building Products (brick and tile), Sanitary ware (toilets and sinks), Tableware and high temperature kilns (plates, teapots, vases etc). *The temperature of kilns can go up to 1200°C or even more. The limitation of the barrier box is 350°C under kiln car. Thermal Duration Heat Sinks Here water stored in a tank acts as a phase change material. Maximum Temperature Aluminum heat treatment process (T6) with age hardening process *After water quenching 8 hour...

Open the catalog to page 7

THERMAL BARRIER BOX EVAPORATIVE BARRIERS Thermal Duration When evaporative barriers are used more temperature and duration upto 1000°C can be achieved. Heat Sinks Here water stored in a tank acts as a phase change material. Maximum Temperature Slab Reheat, Billet reheat process and other high temperature and duration heat treatment processes without quenching can be achieved. *Size of the barrier box with fiber blanket cage will be increased by 100mm each side. *Customized size barrier boxes are also available depending upon temperature and time duration.

Open the catalog to page 8

THERMOCOUPLE PROBES Magnetic Clamp Thermocouple Range – 260 °C Length – 1.5 meter Ref. No. 5000-02 Mini mag probe Range – 260 °C Length – 1.5 meter Ref. No. 5000-07 Sheet Clamp Thermocouple Range – 260 °C Length – 1.5 meter Ref. No. 5000-08 Exposed Junction Range – 260 °C Length – 1.5 meter Ref. No. 5000-04 Surface Magnetic probe Range – 300 °C L

Open the catalog to page 9

Pyrotech Group Company www.pyrotechindia.com Tempsens Instruments (l) Pvt. Ltd. B-188A, Road No.5, M.I.A., Udaipur-313003 (Rajasthan) INDIA Ph.:+91-294-3507700, Fax.:+91-294-3507731 Email: info@tempsens.com Tempsens Instruments GmbH Loehestrasse 37, 53773 Hennef, GERMANY Ph.: +49 2242 8703-22, Fax: +49-2242-8703-20, Email:basant@tempsens.com hmueller@tempsens.de Pt. Tempsens Asia Jaya Jl. Jembatan lll Komplex F.77 No. 6C, Jakarta Utara14450, Indonesia Hp. : (+62)877 8080 4433, Telp. : (+62) 21 666 04006, Fax : (+62) 21 661 6789 Email : support@tempsens-asia.com

Open the catalog to page 10All TEMPSENS catalogs and technical brochures

-

Nickel & Thermocouple Alloy

26 Pages

-

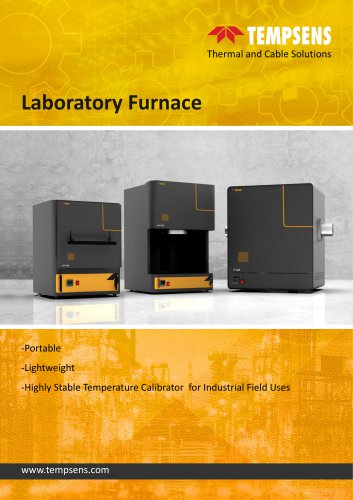

Laboratory Furnace

13 Pages

-

Tempsens Product Catalogue

60 Pages

-

Thermowells and accessories

12 Pages

-

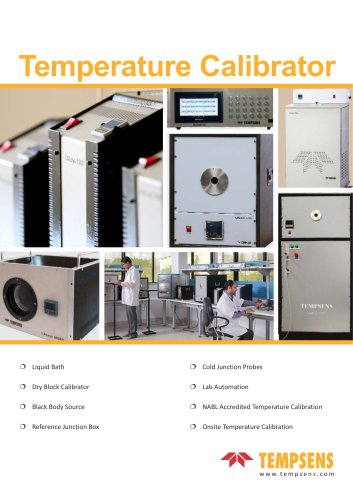

Temperature Calibrators

34 Pages

-

Petrochemical Industry

22 Pages

-

Cables & Wires

16 Pages

-

Petro-Chemicals Industry

12 Pages

-

Miniature Thermocouple

1 Pages

Archived catalogs

-

Tempsens Products

6 Pages

-

Product overview

2 Pages