Website:

TEMPSENS

Website:

TEMPSENS

Group: Pyrotech

Catalog excerpts

Temperature Sensors Glass Industry Glass Level Probe Calibration Services

Open the catalog to page 1

TEMPSENS Instruments (I) Pvt. Ltd is a part of Pyrotech group which was established by four technocrats in 1976 at Udaipur, with its first product as Thermocouples and RTDs. Today Tempsens is one of the world's largest solution provider for thermal engineering products - ie. Temperature Sensors, Infrared Pyrometers, Heaters and Cables. The headquarters are based in India and state of art manufacturing facility in Germany. Tempsens is an ISO 9001:2015, ISO 14001:2015, OHSAS 18001 certified company with NABL Accredited Laboratories. The company is involved into manufacturing of Thermocouples,...

Open the catalog to page 2

■■facilities WELDING AND BRAZING • Laser Welding Machines • Programmable Micro Plasma Welding Machines • TIG Welding Machines with Pulse Modulation And Rotary Positioner • Induction Brazing Machines • Resistance Welding Machines • Brazing Sets (Oxy-Acetative) • Deep Penetration Welding Machines MACHINING • CNC Turning Centers • Turn Mill Centers • VMC Machines • Deep Hole Drilling Machines upto 1500mm Drilling Capacity • Milling Centers CABLE PLANT MACHINERY • FEP/PFA Extrusion Lines • PVC Extrusion Lines • Silicon Extrusion Line • Laying Lines • Braiding Machines - High Speed and Regular •...

Open the catalog to page 3

Glass Melting Furnace includes a melting chamber in which solid batch materials are heated to produce molten glass. The arch of this melting chamber is known as crown. To measure and control the temperature of furnace crown is important, because with the correct temperatures one can improve the service life of crown, as the overheating of the crown may cause of early erosion of crown refractory and on the other side if the temperatures are low, it can affect the melting efficiency and will increase the fuel consumption. The highest temperature in melting furnace is at crown. To select the...

Open the catalog to page 5

Same as crown, to measure the correct temperatures at furnace bottom results in higher service life of bottom blocks. Bottom blocks are the costliest part of a melting tank. Bottom thermocouples are used to get efficient operation of Glass Furnace. Even 2 - 3 Degrees higher or lower temperature can affect the fuel consumption of furnace. Tempsens Thermocouples proved the "whole campaign life" goal on many projects. On this application hole can be through to immerse a glass immersion thermocouple, which will be with hardened platinum/platinum alloy thimbles over ceramic protection tubes. If...

Open the catalog to page 6

In distributor and fore hearths temperature measurement and control is most important. The glass fore-hearth control system includes a temperature sensing system and control system. The temperature sensing system includes an arrangement of prepositioned temperature sensors. Simplex thimble thermocouples and tri-level / triplex thermocouples consist of an assembly of a bottom, middle and top thermocouples for sensing the vertical temperature profile of the molten glass at a fixed location. The output signals from these temperature sensors are received by controllers of the control system...

Open the catalog to page 7

In TI/GL/01 uses small thimble length. That model is economic and commonly used worldwide, normally it gives very good service life but the only disadvantage is recovery of platinum as the ceramic tube is in flame contact and if it breaks, one can loose the whole thimble. In TI/GL/02 thimble length is long, it is from glass immersion to roofing block and thimble shall be in flame, there is no joint of ceramic tube & PT thimble in fore hearth atmosphere. It is quite popular design in heavy draw fore hearths. Where glass draw is high, customer can choose as per their requirement. All...

Open the catalog to page 8

In distributor and fore hearths rear and middle zone most of the glass companies use this simplex small thimble thermocouple. This is the substitute of fibre optic pyrometer. With Pyrometer customer can get only glass surface temperature but using this thermocouple, customer can get glass immersion temperatures. It is commonly used in all container glass industries. We manufacture conditioning zone trilevels and rear /middle zone simplex thermocouples from same batch element with same accuracy, our customer can get relative temperatures with high accuracy. At three levels at B-Bottom,...

Open the catalog to page 9

Glass level probe for glass level control is made with Pt alloy probe. Inside and outside protection is with recrystallised alumina tubes, with this customer can replace old fashioned water cooled level probes. These probes are available in different type of hangers as per customer requirement. Service life is very good. All lengths & dia are available as per site needs. Type TI/GL/03 Measuring Range Glass Contact. Sensor Type Pt. or Pt.Rh alloy Electrode. Protection Sheathing Recrystalised Alumina KER-710 (C-799) Tube with hole at one end. With PT Alloy Tip for Glass Level Sensing....

Open the catalog to page 10

^ SPOUT THERMOCOUPLES In container glass industries Spout Bowl glass temperature is very important. To measure it, we designed Spout Bowl Thermocouples in nobel metal with platinum thimble. It is immersed through side and user can get correct temperature of molten glass just before glass cutting. Length as perapplication need. Measuring Range 100 to 1600°C. Sensor Type "R"/ "S"/ "B". Protection Sheathing Recrystalised Alumina KER-710 (C-799) Tube with hole at one end. Special Hardened Platinium / PT Alloy Thimble. Application Spout Bowl.

Open the catalog to page 11

Ceramic Tubes Open Ended Close Ended Insulators Material Type Standard Length Ceramic -Alumina Tubes, Type DIN C-799, Type 610, K 80 etc. One End Closed / Open Both End. 350, 530, 600, 650, 740, 900, 1030, 1200, 1430, 2000, 2300mm etc. 5mm to 24 mm, other diameters also available on request. Properties Al2O3-content Color Specific gravity Water absorption Flexural strength Max. temp. use Thermal conductivity Temperature stability Chemical resistivity Te value Recrsytallised Alumina Tube (DIN C-799) 99.7% Yellow/ivory 3.85 0 360 1.700°C 28 good/satis. very good 1.000 High Temperature Cables...

Open the catalog to page 12All TEMPSENS catalogs and technical brochures

-

Nickel & Thermocouple Alloy

26 Pages

-

Thermal Profiling System

10 Pages

-

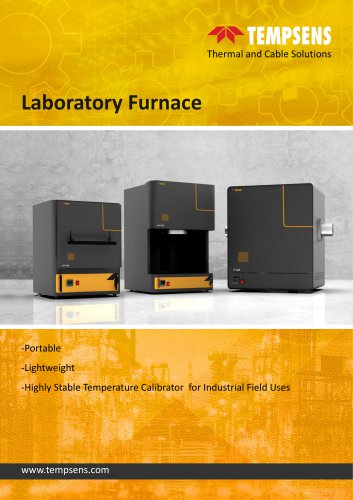

Laboratory Furnace

13 Pages

-

Tempsens Product Catalogue

60 Pages

-

Thermowells and accessories

12 Pages

-

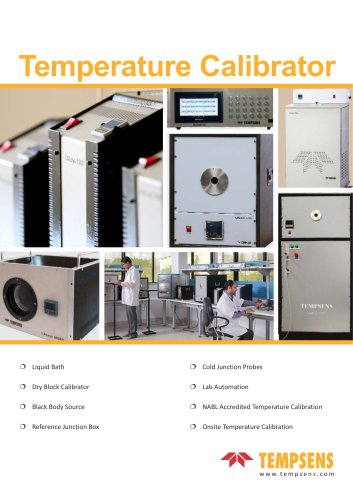

Temperature Calibrators

34 Pages

-

Petrochemical Industry

22 Pages

-

Cables & Wires

16 Pages

-

Petro-Chemicals Industry

12 Pages

-

Miniature Thermocouple

1 Pages

Archived catalogs

-

Tempsens Products

6 Pages

-

Product overview

2 Pages