Catalog excerpts

This innovative sensing solu- tion is applicable to industries that convert plies of materials into embossed napkins, paper towels, plastic-lined paper table cloths, and other consumer Sensing System uses sors to eliminate the costly prob- lem of broken plies wrapping around, heating up, and damag- ing embossing rolls, as well as the resulting downtime required to make necessary repairs. They also eliminate false trips or no trips at all resulting from dusty environments, or prob- lems associated with sensors not immune to changing colors Equipped with up to three pairs (transmitter and receiver) monitors the entire width of the embossing rolls. Machine speeds in excess of 26 feet per second as well as dust, differ- ent colors and textures have no effect on the sensing capability of these sensors. During opera- tion, when one of the sensors missing ply or even a hole in the puts an alarm signal. The signal can be used to alert an opera- rolls, or automatically stop the bossing rolls are saved from severe damage and time-con- suming repairs. After the web is rethreaded, the embossing part Using the amount of sound energy transmitted through the plies of material to calibrate the system and detect the breaks, rent ranges from 10 to 40 (typi- provided to calibrate the detec- sometimes change the various settings. A digital display pro- vides various information on each of the sensor pair chan- nels and a numeric display shows, sequentially, the signal embossing rolls embossing rolls • Alarm signal can alert operator, automatically shear the paper ahead • Uses up to three pairs MICROSONIC® ultra-

Open the catalog to page 1

How does it work? Ultrasonic energy can be transmitted through certain materials, even numerous plies of paper. With the SS100, the user calibrates the amount of energy passing through the plies. This calibration automatically adjusts the gain to obtain an output which is about 25% of full scale. Because many factors can affect the transmission through the good plies of paper, a threshold percentage is set which is then automatically adjusted to track the average signal transmitted through the paper. For example, say the calibrated gain for three plies of embossed paper being run is 25%....

Open the catalog to page 2All Telemecanique Sensors catalogs and technical brochures

-

Photo-electric sensors OsiSense XU

186 Pages

-

Safety light curtains XUSL range

38 Pages

-

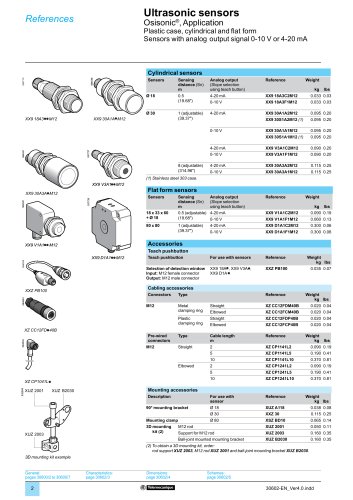

Ultrasonic sensors XX range

79 Pages

-

Limit switches XC Standard range

161 Pages

-

Limit switches XC Special range

67 Pages

-

limit switch XCMN

6 Pages

-

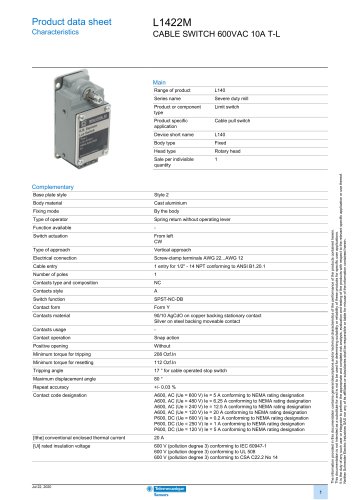

L1422M

2 Pages

-

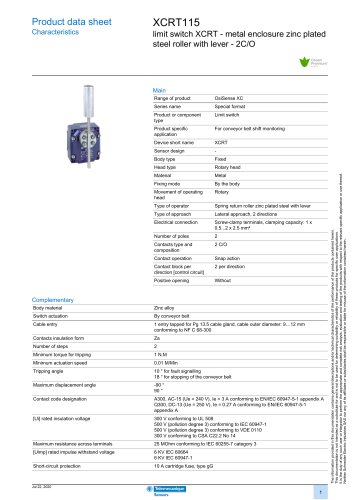

limit switch XCRT

5 Pages

-

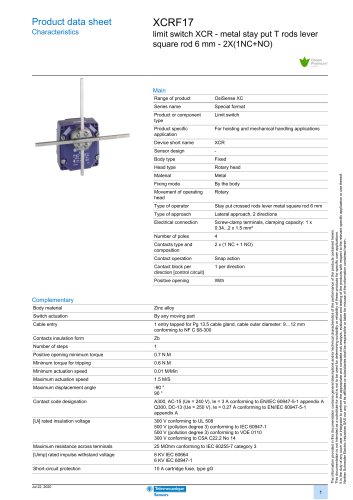

limit switch XCR

5 Pages

-

limit switch XCKL

6 Pages

-

Ultrasonic sensors OsiSense XX

36 Pages

-

Limit switches OsiSense XC Standard

146 Pages

-

New 2011 sensors catalog

24 Pages

-

Model VM18 Proximity

6 Pages

-

Osiconcept Photoelectric Sensor

2 Pages

-

PhotoVirtu™ Photoelectric Sensor

4 Pages

-

Osicap Capacitive Sensors

8 Pages

Archived catalogs

-

Osiris XUA Photoelectric Sensor

2 Pages

-

Virtu™ 30A Catalog

4 Pages

-

Virtu™ Product Brochure

8 Pages