Catalog excerpts

CONSTRUCTION CONSTRUCTION FEATURES / PERFORMANCE FEATURES / PERFORMANCE Permanent magnet on rotor Permanent magnet on stator Electric controller is required Suitable for high torque applications Suitable for low torque applications Higher speed range due to no mechanical limitation imposed by brushes/commutator Typical life expectancy 10,000 to 20,000 hours Lower speed range due to mechanical limitations on the brushes BENEFITS / COMPARISON BENEFITS / COMPARISON Typical life expectancy is 2000 to 5000 hours depending on the application and duty cycle Typically 60-70% efficiency Commutation Method Electronic commutation requiring a driver/controller Uses mechanical commutator to reverse the polarity of the armature electromagnet Brushless design requires little to no maintenance Heat Dissipation Superior thermal characteristics results in better heat dissipation Periodic maintenance is required; can replace brushes for extended life if necessary Internal rotor construction results in limited heat dissipation Low electric noise generation Brushes emit audible nose during rotation Higher manufacturing cost Lower manufacturing cost Operation environment More suitable for normal controlled environments Fuel Controls, missile fin actuators, dental tools, respirators, R/C model airplanes, pumps, robotics, electric and hybrid vehicles, medical equipment, lawn mowers, factory automation, and gate operators Can operate in more extreme environments due to the lack of electronics Printers, toys, semiconductor equipment, packaging machines, automotive motors, wheelchairs, medical equipment, electric toothbrushes, vacuum cleaners, hair dryers, drill screwdrivers and gate operators

Open the catalog to page 1

Email: motors@telcointercon.com

Open the catalog to page 2All Telco catalogs and technical brochures

-

IntelliGreen® 48

1 Pages

-

IntelliGreen® 100

1 Pages

-

comGreenAire® UB

1 Pages

-

FAN & BLOWERS

1 Pages

-

TELCO GEAR

6 Pages

-

ECM Motors

1 Pages

-

Stepper Motor - PM Stepper

1 Pages

-

DC Motor - PMDC

1 Pages

-

DC Motors - Coreless

2 Pages

-

BLDC Motor - NEMA

1 Pages

-

BLDC Motor - Micro

1 Pages

-

AC Motor

1 Pages

-

Line Cord (Assembly)

2 Pages

-

Modular Jack

3 Pages

-

ECM Pump

1 Pages

-

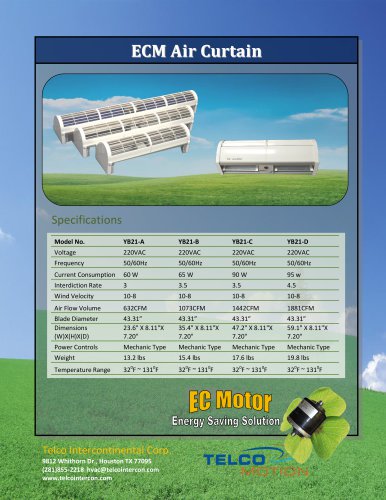

ECM Air Curtain

1 Pages

-

Membrane Switch

1 Pages

-

Touch Screen

9 Pages

-

Gearbox

8 Pages

-

DC Fan

2 Pages

-

AC Fan

1 Pages

-

Non-Captive Shaft Actuator

2 Pages

-

External Actuator

2 Pages

-

Linear Actuator

7 Pages

-

Amplifier

10 Pages

-

Parallel Shaft Gearmotor

25 Pages

-

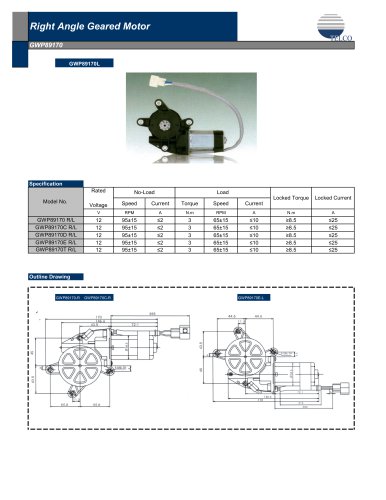

Right Angle Gearmotor

25 Pages

-

NEMA Frame AC

26 Pages

-

PM Stepper

50 Pages

-

NEMA BLDC

5 Pages

-

Outer Rotor Motor

7 Pages

-

C-Frame Shaded Pole Motor

1 Pages

-

Brushless DC Motor

1 Pages

-

Axial Fan Motor

1 Pages

-

TelcoMotion

4 Pages

-

Right Angle Gearmotor

25 Pages

-

Industrial Grade PMDC

5 Pages

-

PSC Motor

24 Pages

Archived catalogs

-

Micro DC Gearmotor Catalog

11 Pages

-

Coreless DC Motor Catalog

6 Pages

-

Micro Brushless DC Motors

13 Pages