Website:

TEKCELEO

Website:

TEKCELEO

Catalog excerpts

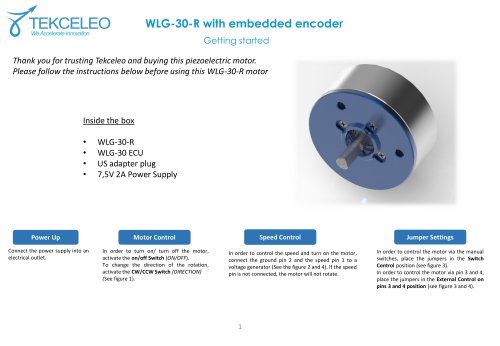

WLG-20-R with embedded encoder Getting started Thank you for trusting Tekceleo and buying this piezoelectric motor. Please follow the instructions below before using this WLG-20-R motor Power Up Connect the power supply into an electrical outlet. WLG-20-R WLG-20 ECU US adapter plug 9V 2A Power Supply Speed Control Motor Control In order to turn on/ turn off the motor, activate the on/off Switch (ON/OFF). To change the direction of the rotation, activate the CW/CCW Switch (DIRECTION) (See figure 1). In order to control the speed and turn on the motor, connect the ground pin 2 and the speed pin 1 to a voltage generator (See the figure 2 and 4). If the speed pin is not connected, the motor will not rotate. Jumper Settings In order to control the motor via the manual switches, place the jumpers in the Switch Control position (see figure 3). In order to control the motor via pin 3 and 4, place the jumpers in the External Control on pins 3 and 4 position (see figure 3 an

Open the catalog to page 1

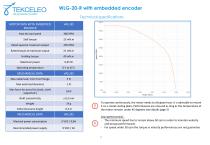

WLG-20-R with embedded encoder Technical specifications MOTOR DATA WITH EMBEDDED ENCODER Stall torque Rated speed at maximum output Rated torque at maximum output Holding torque Maximum power Operating temperature MECHANICAL DATA Max radial load, 5mm from flange Max axial load dynamics Max force for press fits (static, shaft supported ) Shaft concentricity 8 Electrical wire length MECHANICAL DATA Maximal power consumption Recommended power supply To operate continuously, the motor needs to dissipate heat. It is advisable to mount it on a metal cooling plate. Performances are ensured as long...

Open the catalog to page 2

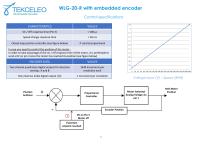

WLG-20-R with embedded encoder Control specifications CHARACTERISTICS Speed change response time Closed loop position controller (see figure below) In case you need to control the position of the motor : In order to take advantage of the on / off response time of the motor, it is preferable to send a 0V on pin 3 once the motor has reached its position (see figure below) ENCODER DATA Two channel quadrature digital outputs for direction sensing : A and B 1440 increments per revolution each One channel, Index digital output I (Z) Position SetPoint Voltage input (V) / Speed (RPM) Motor...

Open the catalog to page 3

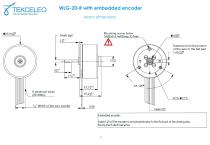

WLG-20-R with embedded encoder Motor dimensions

Open the catalog to page 4

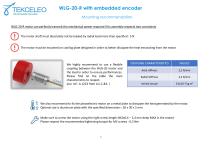

WLG-20-R with embedded encoder Mounting recommendation WLG-20-R motor can perfectly transmit the mechanical power required if its assembly respects two constraints The motor shaft must absolutely not be loaded by radial load more than specified : 5 N The motor must be mounted on cooling plate designed in order to better dissipate the heat emanating from the motor We highly recommend to use a flexible coupling between the WLG-20 motor and the load in order to ensure performances. Please find on the table the main characteristics to respect. (our ref : A 1223 from A.C.C.&S. ) COUPLING...

Open the catalog to page 5

WLG-20-R with embedded encoder Control specifications PIN 1 Speed control using analog voltage 0 – 3,3 VDC On Off digital control TTL level signal (0 or 5 VDC) CW / CCW digital control TTL level signal (0 or 5 VDC) Incremental encoder signal A (1440 increments per rotation) Incremental encoder signal B (1440 increments per rotation) INPUT / OUTPUT Incremental encoder index JUMPER CONFIGURATION Switch control Pins dimensions Board dimensions

Open the catalog to page 6