Catalog excerpts

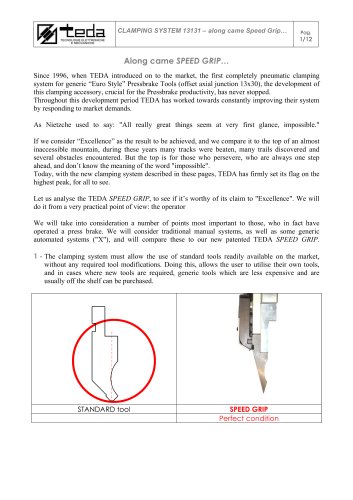

Along came SPEED GRIP. Since 1996, when TEDA introduced on to the market, the first completely pneumatic clamping system for generic "Euro Style" Pressbrake Tools (offset axial junction 13x30), the development of this clamping accessory, crucial for the Pressbrake productivity, has never stopped. Throughout this development period TEDA has worked towards constantly improving their system by responding to market demands. As Nietzche used to say: "All really great things seem at very first glance, impossible." If we consider "Excellence" as the result to be achieved, and we compare it to the top of an almost inaccessible mountain, during these years many tracks were beaten, many trails discovered and several obstacles encountered. But the top is for those who persevere, who are always one step ahead, and don't know the meaning of the word "impossible". Today, with the new clamping system described in these pages, TEDA has firmly set its flag on the highest peak, for all to see. Let us analyse the TEDA SPEED GRIP, to see if it's worthy of its claim to "Excellence". We will do it from a very practical point of view: the operator We will take into consideration a number of points most important to those, who in fact have operated a press brake. We will consider traditional manual systems, as well as some generic automated systems ("X"), and will compare these to our new patented TEDA SPEED GRIP. 1 - The clamping system must allow the use of standard tools readily available on the market, without any required tool modifications. Doing this, allows the user to utilise their own tools, and in cases where new tools are required, generic tools which are less expensive and are usually off the shelf can be purchased. (IL) f STANDARD tool SPEED GRIP Perfect condition

Open the catalog to page 1

The clamping unit must have minimum interfrence to both the front and rear, in order to allow the execution of flanges with high returns. Manual clamping SPEED GRIP Perfect condition The locking system has to provide ALWAYS the possibility to reverse the tool, by manual clamp adjusted from the front side of the Pressbrake. Manual clamping Manual front clamping Manual back clamping with rear fixing screws difficult condition SPEED GRIP Automatic front clamping Manual back clamping with frontal adjustment Perfect condition

Open the catalog to page 2

The locking system has to allow reversing of the tools by clamping on the back of the unit, whilst the front side of the Pressbrake is left free. In this way it is possible to bend flanges, without obstacles limiting the part profile. D ^ with single rear bracket front side area completely free Manual clamping SPEED GRIP Automatic rear clamping rear fixing screws - difficult with manual rear clamping Perfect condition

Open the catalog to page 3

The optimal clamping system MUST allow the vertical insertion of the tools, from the front of the Pressbrake, with either full length or sectional tools, without restrictions of any kind. o _Manual clamping lateral insertion only_ SPEED GRIP VERTICAL insertion for any tool length Perfect condition The clamping system also, MUST allow the lateral insertion of tools, so that the sectional tools can be easily positioned along side other tools that may be much heavier and harder to position. Manual clamping EED GRIP Perfect condition

Open the catalog to page 4

In order to guarantee quality and performance, superior to any kind of manual clamping system, the automatic system must ensure total freedom of the working area (both on the front and on the back) from the pneumatic connections. In this way only, the operator will be totally free, to perform all complex bending operations. They will be able to fully exploit the speed and convenience of an automatic clamping system without compromising the advantage of a manual system. W°(\ 1 r 1 r B (&) & J L B (S) & o o o o Automatic clamping "X" SPEED GRIP with "STAR S Total absence of feeding tubes_...

Open the catalog to page 5

TEDA managed to get to where the others could not. Thanks to its "STAR SYSTEM" the operator has the best of both worlds, with all the advantages of an automatic clamping system along with the essential capability to remove one or more units at any machine position, in a quick and immediate way without any connection modifications. Magic? No, STAR SYSTEM! SPEED GRIP with "STAR SYSTEM" No feeding tubes - no working limits Perfect conditior The STAR system is unique - it recognises what it is clamping! For example; it recognises the Speed Grip unit, or in cases where a tool is clamped under...

Open the catalog to page 6

The best locking system has to grant a safe tool support in the bending position before starting the bending operation. This condition is essential while working with thin and sheets, and to ensure the perfect lifting and alignment of even the smallest sectioned tools. il1 r ny n j Vj B - clamping 1 in vertical plane [g 1 A - lifting until the tool is placed ? T Manual clamping SPEED GRIP Automatic clamping in two stages A + B First "Bed-In" in order to get a safe tooling seat Perfect condition

Open the catalog to page 7

CLAMPING SYSTEM 13131 - along came Speed Grip. Pag. 8/12 10 - During the insertion/jection oprations, the tool must pr驩sent ease of handling and total safety against accidental falls. Only if these conditions are satisfied the operator can work in compliance with the safety regulations, quickly and without undue efforts that would surely compromise productivity. ^^^^ Frontal insertion Frontal ejection SPEED GRIP Free frontal insertion with automatic hooking WITHOUT UNDUE EFFORTS Frontal ejection through lifting and small rotation of the tool - accidental release = completely impossible...

Open the catalog to page 8

CLAMPING SYSTEM 13131 - along came Speed Grip. Pag. 9/12 Even though standard tools have identical blade profile configurations, they can prsent discrepancies in the junction tangs which are less important, depending on the tool manufacturer. The locking system should ideally allow the use of standard tools with large tolerances on the junction tangs and, of course, without need of tooling modifications. r 3 ' 3,0 r O'O 1 BASIC UITH GROOVES 3,5 _ r s LU rit r o L LOU GRINDING Standard Tools Discrepancies in the junction tangs SPEED GRIP Elastic lifting system with AUTOMATIC ADAPTATION to...

Open the catalog to page 9All TEDA srl catalogs and technical brochures

-

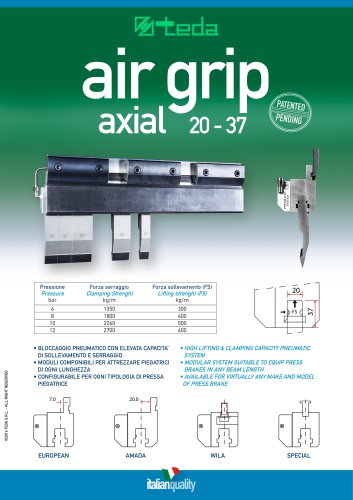

Air Grip

2 Pages

-

Speed grip

4 Pages

-

TOOLSQUARES

1 Pages

-

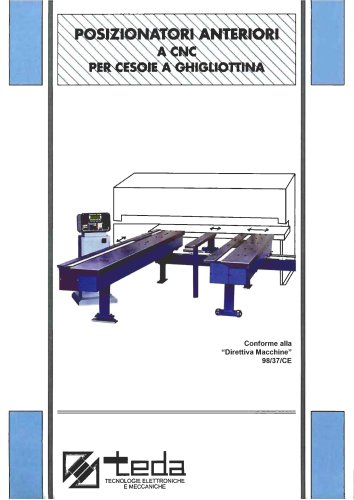

Front positioners for shears

2 Pages