Website:

Tecnotion

Website:

Tecnotion

Catalog excerpts

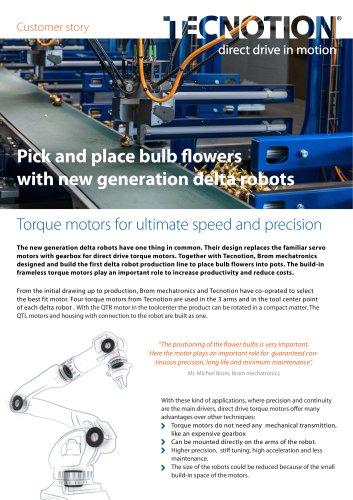

Customer story Pick and place bulb flowers with new generation delta robots Torque motors for ultimate speed and precision The new generation delta robots have one thing in common. Their design replaces the familiar servo motors with gearbox for direct drive torque motors. Together with Tecnotion, Brom mechatronics designed and build the first delta robot production line to place bulb flowers into pots. The build-in frameless torque motors play an important role to increase productivity and reduce costs. From the initial drawing up to production, Brom mechatronics and Tecnotion have co-oprated to select the best fit motor. Four torque motors from Tecnotion are used in the 3 arms and in the tool center point of each delta robot . With the QTR motor in the toolcenter the product can be rotated in a compact matter. The QTL motors and housing with connection to the robot are built as one. “The positioning of the flower bulbs is very important. Here the motor plays an important role for guaranteed continuous precision, long life and minimum maintenance”. Mr. Michiel Brom, Brom mechatronics With these kind of applications, where precision and continuity are the main drivers, direct drive torque motors offer many advantages over other techniques: Torque motors do not need any mechanical transmittion, like an expensive gearbox Can be mounted directly on the arms of the robot. Higher precision, stiff tuning, high acceleration and less maintenance. The size of the robots could be reduced because of the small build-in space of the motors

Open the catalog to page 1

Frameless torque motors for the new generation delta robots The 4 integrated torque motors increase the dynamic accuracy and speed of the robot. QTL210 - Arms delta Robot This motor has a large inner diameter suitable to route multiple cables through, allowing flexibility in the application. It can be integrated directly into the machine structure which could reduce the size of the robot Ultimate torque: 173 – 346 Nm Peak torque: 140 – 281 Nm Continuous torque: 65 – 142 Nm The build heights are: 210-65 // 210-85 // 210-105 “Tecnotion really helped with their expertise of movement profiles...

Open the catalog to page 2All Tecnotion catalogs and technical brochures

-

TS Iron core series

2 Pages

-

TxX ironcore leaflet

2 Pages

-

Motor portfolio

6 Pages

-

Vacuum Gen 2 V1.4

16 Pages

-

Ironless linear motor brochure

28 Pages

-

Vacuum-UXXV G2 series

2 Pages

-

Vacuum-ULV G2 series

2 Pages

-

Vacuum-UMV G2 series

2 Pages

-

QTL 485 Torque motors

2 Pages

-

QTL 385 Torque motors

2 Pages

-

QTL 310 Torque motors

2 Pages

-

QTL 290 Torque motors

2 Pages

-

QTL 230 Torque motors

2 Pages

-

QTL 210 Torque motors

2 Pages

-

QTR 160 Torque motors

2 Pages

-

QTR 133 Torque motors

2 Pages

-

QTR 105 Torque motors

2 Pages

-

QTR 78 Torque motors

2 Pages

-

QTR 65 torque series

2 Pages

-

UXX SERIES

2 Pages

-

UXA SERIES

2 Pages

-

UF SERIES

2 Pages

-

UL SERIES

2 Pages

-

UC SERIES

2 Pages

-

UM SERIES

2 Pages

-

TBW serie

2 Pages

-

TB series

2 Pages

-

TL Series

2 Pages

-

TM series 2.2

2 Pages

-

TL48

2 Pages

-

Simulation tool

2 Pages

-

transport conveyer

5 Pages

-

Low voltage

2 Pages