Catalog excerpts

eRESEARCH AND PRODUCTION ENTERPRISE iimiim liuiiii flllllU"Rl >■■■■■»< Mllllllllll IUIIBII llllllllllll Hunt! ilementation experience

Open the catalog to page 1

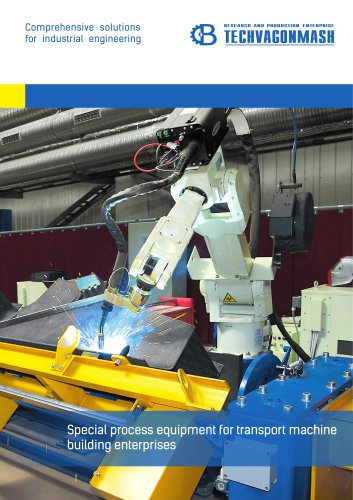

RESEARCH-AND-PRODUCTION ENTERPRISE ROBOTIC SYSTEM FOR CENTER SILLS WELDING The equipment is designed and manufactured under Tikhvin Freight Car Building Plant order. It is a unique , one-of-a-kind system for robotic submerged arc welding of longitudinal seams of all freight car center sill models. The system allows to perform welding of workpieces in "normal" position as well as in "reverse" position ensuring reverse deflection during welding in order to prevent welding deformations. Robots application allows to perform fast and flexible changeover to different items. In this case the robot...

Open the catalog to page 2

RESEARCH-AND-PRODUCTION ENTERPRISE STAND FOR AUTOMATIC WELDING OF A CENTER SILL WITH I-BEAM The stand is designed and manufactured under Tikhvin Freight Car Building Plant order. The stand of automatic welding has original design and technology concepts which do not have analogues in railroad car building. It fully operates in automatic mode on assembly and automatic welding of the workpiece. Approved configuration of the stand for automatic welding of center sill to I-beam is typical for all the railroad car building plants, but this stand has distinctive features: 4 -beam centering about...

Open the catalog to page 3

RESEARCH-AND-PRODUCTION ENTERPRISE MULTIPURPOSE LINE FOR ASSEMBLY AND AUTOMATIC WELDING OF GIRDERS The line is a multipurpose equipment allowing to manufacture 380 - 700 mm high girders of semitrailers. The first position involves girders assembly and their automatic welding from the front, then the item is turned over 1800 with a built-in rotator, and after that welding from the reverse side takes place. Automatic welding is performed by means of traveling gantry plant. Actuation of the gantry and the torches is performed by means of servodrives which ensures travel and positioning...

Open the catalog to page 4

RESEARCH-AND-PRODUCTION ENTERPRISE LINE FOR ASSEMBLY AND WELDING OF ELECTRIC LOCOMOTIVES SIDE-FRAMES The equipment is manufactured for Novocherkassk Electric Locomotives Plant. This line is multipurpose one - it ensures assembly and welding of sideframes of all produced models of the electric locomotives. The line involves CMT Twin (Fronius, Austria) welding technique. It allowed to reduce occupied area, increase efficiency, minimize deformations after welding. 2 1 Gantry for welding of strips transverse seams 1 – stand for assembly and automatic welding of strips 2 – gantry for welding of...

Open the catalog to page 5

RESEARCH-AND-PRODUCTION ENTERPRISE LINE FOR VESSELS ASSEMBLY AND AUTOMATIC WELDING This center is multipurpose one and it allows to to localize vessel production on a small area. It ensures output of a wide range of vessels with different diameters with a slight realignment on one plant. The line is equipped with an external clamp which automatically provides sections edges overlapping for welding which significantly decreases assembly labour intensity and ensures quality assembly for automatic welding. Assembled vessel elements are welded automatically with plants for welding of internal...

Open the catalog to page 6

RESEARCH-AND-PRODUCTION ENTERPRISE PASSENGER CAR ROOF SHEATHING WELDING The equipment is manufactured for Tver Railroad Car Building Works. The stand is unique one and does not have analogues. Welding on this stand is performed in automatic mode without operator's participation, applying laser seam tracking system over the whole length of the workpiece. The stand is multipurpose and flexible one. ROBOTIC CENTER FOR WELDING OF FREIGHT CARS CROSS BEARERS The plant provides for ability to automatically readjust for output of eight types of roof sheathing rapidly If there is a need then it is...

Open the catalog to page 7

RESEARCH-AND-PRODUCTION ENTERPRISE AUTOMATED CENTER FOR WELDING OF GONDOLA CAR SIDE WALLS ROBOTIC CENTER FOR WELDING OF GONDOLA CARS END WALLS All the operations of clamping and welding of the item are performed automatically, operator just needs to control the welding process and provide loading/unloading of the workpieces. Applying of Festo intellectual pneumatic automation allows to control workpiece assembly accuracy, to inform the worker about deviations, minimizes human factor. After welding from the reverse side the end wall is rotated by 1800 with a built-in rotator and laid on the...

Open the catalog to page 8

Model range and rotators' load capacity vary from several hundreds of kilos to tens The rotators are equipped with light and audio alarms. Control system ensures synchronization of lift, swing and motion Rotatorwith lifting supports, load capacity -15 t Body rotator Rotatorwith lifting supports, load capacity k -1 RESEARCH AND PRODUCTION ENTERPRISE Chain rotator Overhead rotator Rotator for car roof sheathing Rotatorwith lifting supports, load capacity - 40 t

Open the catalog to page 9

RESEARCH-AND-PRODUCTION ENTERPRISE ASSEMBLY EQUIPMENT The company is one of the main manufacturers of assembly equipment for different types of heavy engineering factories products. We offer solutions for one type production as well as multipurpose stands allowing to assemble several product models. We stick to the following concept of assembly equipment construction in our developments: 4 equipment has to be multipurpose one ; 4 minimum dependence on human factor has to be ensured; 4 equipment must not allow to make defective items (equipment informs operator about a defective part or...

Open the catalog to page 10

RESEARCH-AND-PRODUCTION ENTERPRISE EQUIPMENT FOR VESSELS MANUFACTURE Research and production enterprise "Techvagonmash" has a rich long-term experience in production of special process equipment for vessels manufacture. We offer comprehensive solutions in vessel production automatization projects: conveying systems for workpieces and fininshed items transfer, automatic lines for sheet parts welding, assembly equipment for head-to-shell welding, line for vessels automatic welding. Equipment is designed according to the output production program and customer's production conditions. Sheets...

Open the catalog to page 11All Techvagonmash catalogs and technical brochures

-

Company presentation

26 Pages

-

Industrial paint booths

7 Pages