Catalog excerpts

Techne Industrial Fluidised Baths How to use an Industrial Fluidised Bath to quickly and cost effectively clean extrusion tooling without the risk of damage to the tools

Open the catalog to page 1

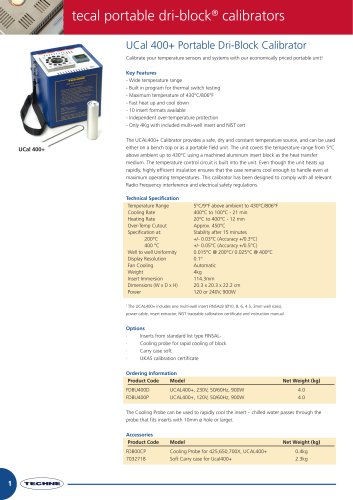

Industrial fluidised baths About After years of demonstrated success, plastic manufacturers have come to depend on Techne fluidized baths for safe, efficient and cost effective cleaning of tooling, components, systems and parts (dies, breaker plates, nozzles, tools, tips, spinnerets, extruder screws, manifolds, etc.) Fluidized baths will remove almost all polymers, including plastic, paint, epoxy, rubber and adhesives, as well as other hydrocarbon-based products such as oils, fluids, grease, lubricants and coatings. Parts immersed into a fluidized bath are cleaned by the high temperature...

Open the catalog to page 2

Industrial fluidised baths IFB-51 & IFB-52 Models IFB51 and IFB52 Industrial Fluidized Baths are our most popular units due to their economical price and smaller size. They offer a front panel mounted Rotameter for adjustment of the fluidizing air flow and are ready for use out of the box with the included charge of aluminum oxide. Models IFB101 and IFB111 step up in diameter and depth from the IFB51 and 52. These baths also have a 3 phase voltage supply requirement to handle the large power capacity of the heaters. All larger baths on the following pages also run on 3 phase power. IFB-201...

Open the catalog to page 3

Industrial fluidised baths IFB-121 & IFB-131 Models IFB121 and IFB131 are our largest capacity fluidized baths. Typical applications include cleaning large dies and breaker plates as well as long extruder screws and manifolds. A customer sourced hoist or lift would be used to retrieve the basket with parts from the unit. Temperature range Overall size (H x W x D), mm. Working volume (diam. x depth*), mm Maximum work load (kg) Display accuracy ** Typical stability ** Aluminum oxide required (kg) Aluminum oxide supplied (kg) Voltage supply required (50/60hz) Power requirements Unit weight...

Open the catalog to page 4

Industrial fluidised baths AB100 Afterburner Model AB100 is designed to reduce smoke emission from the exhaust gas flue of most all Techne fluidized bath cleaning systems. The Afterburner consists of a burner plate mounted within a thermally insulated combustion chamber. The input to the combustion chamber is designed to mate directly to a standard Techne extraction fan, while the output is suitable for connection to an exhaust stack. The AB100 will not remove hydrogen chloride from exhaust gases. The SR100 fume scrubber should be placed before the afterburner whenever considerable...

Open the catalog to page 5

Industrial fluidised baths CN-100 Cyclone and Collection Bin The CN–100 is an efficient wall mounted unit which can extract more than 99% of any fluidising medium that may be carried over into the bath exhaust system when the extraction fan is in operation.The cyclone includes a collection bin which allows alundum carried over to be collected and returned to the bath for re-use. An extraction fan and cyclone are recommended unless a suitable extraction hood or fume extraction system is already in place. The cyclone has no moving parts and requires no power and is simply connector via the...

Open the catalog to page 6

Industrial fluidised baths Before and after How to use an Industrial Fluidised Bath to quickly and cost effectively clean extrusion tooling without the risk of damage to the tools. Cleaning parts in the IFB bath Part before cleaning Insert part to be cleaned into the basket View of the part in the basket IFB51 setup with fume extraction accessories View inside the extraction collar. Insert the basket with part into the bath at temperature Immerse the basket into the bath and cover with the lid Small amount of fumes and smoke are exhausted out to the right Typically 25 minutes at burn-off...

Open the catalog to page 7

w w w. t e c h n e-calibration.com For the Rest of The World, contact: Bibby Scientific Ltd. Beacon Road, Stone, Staffordshire ST15 0SA United Kingdom Tel: +44 (0)1785 812121 Fax: +44 (0)1785 813748 Email: calibration@bibby-scientific.com www.techne-calibration.com For the America’s and Canada, contact: Techne Incorporated, 3 Terri Lane, Suite 10 Burlington, NJ 08016 USA Toll free: 800-225-9243Tel: 609-589-2560 Fax: 609-589-2571 Email: labproducts@techneusa.com www.techneusa.com Middle East region, contact: Bibby Scientific Middle East Ltd P O Box 27887 Engomi 2432 Nicosia Cyprus Tel: 357...

Open the catalog to page 8All Techne Calibration catalogs and technical brochures

-

Dynalene SF

2 Pages

-

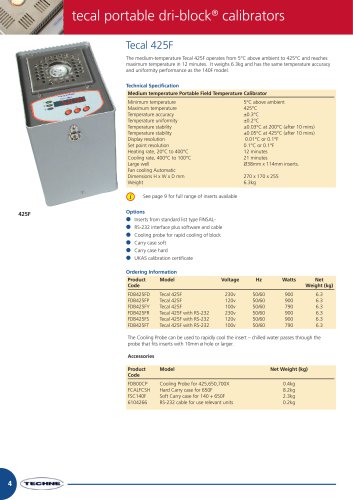

Tecal 425F

1 Pages

-

Tecal 425S Calibrator

20 Pages

-

Tecal 425H Calibrator

30 Pages

-

Tecal 140S Calibrator

18 Pages

-

Tecal 140H Calibrators

30 Pages

-

handheld thermometers

1 Pages

-

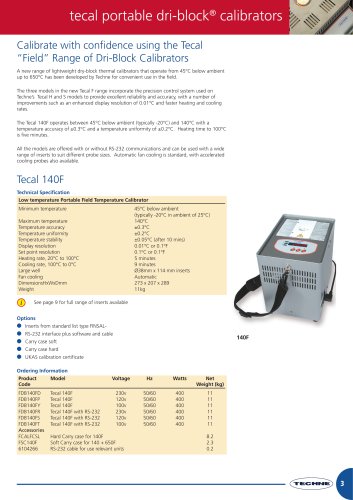

Tecal 140F

1 Pages