Catalog excerpts

Optimize CAD/CAM processes with Tebis software. Model making Prototype manufacture Mold manufacture Die manufacture Gauge manufacture Industrial manufacture Aircraft construction

Open the catalog to page 1

Tebis Ba se Generating and modifying wire frame models. Analysis, navigation and documentation. 12 CAD interfac es Exchanging data efficiently. 13 Surfac e design Generating and modifying surface models. 14 Advanced surfac e design Specialized high-end functions. 15 Digitized data proc essing Digitizing surfaces and optimizing STL meshes. 16 Ra pid Surfac e Creat ion (RS C) Easy generation of high-quality surfaces. 17 Elect rod e design Database-supported design with simulation on the virtual model. 18 Feat ure design Database-assisted handling of drilled objects of any complexity. 19 4Page...

Open the catalog to page 2

2.5D drilling and milling Fully automatic, knowledge-based NC machining. 22 3+2 axis roughing Shorter run times and less wear on tools. 23 3+2 axis finishing Optimum surface quality for components of any complexity. 24 3+2 axis residual STOCK Remo val Field-tested strategies to reduce run times. 25 3+2 axis tube milling 3-axis machining of bent intake and exhaust ducts. 26 5-axis simulta neous milling The fastest way to achieve smooth surfaces. 27 5-axis laser cutt ing For try-outs, prototypes and series. 28 5-axis trimm ing For trimming components made of composite materials 29 4-axis wire...

Open the catalog to page 3

Companies in manufacturing-intensive industries use Tebis software to organize their CAD/CAM process chains, thereby creating a robust and reliable platform. Tebis CAD/CAM and Viewer stations have become established as essential elements in high-efficiency manufacturing process chains, particularly in the automotive, aerospace and industrial manufacturing sectors. Tebis workstations can be smoothly integrated into design departments’ existing CAD infrastructure, and Tebis supplies the machines with safe NC programs required to manufacture the components. The CAD interfaces let you import...

Open the catalog to page 4

Tebis proc ess chains Tebis CAM modules create safe and run time-optimized NC programs from users’ tested and saved strategies and input parameters. Tebis supports the manufacturing processes 2.5D drilling and milling, 3 to 5-axis roughing and finishing of surfaces, contours and tubes, 5-axis laser cutting, 5-axis trimming and 4-axis wire EDM. The integrated tool library, saved machining templates and realistic simulation options generate process-safe NC programs that are easy on your tools and require little programming work and minimal run times on the machines. You can use the...

Open the catalog to page 5

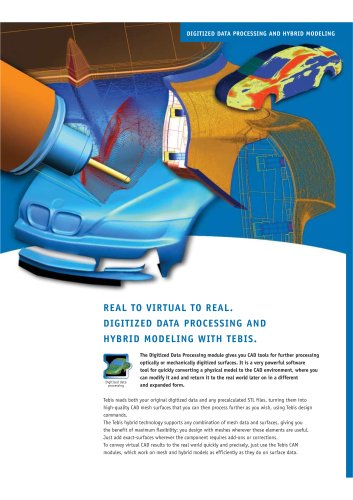

Tebis software helps optimize processes. Tebis prod uct philosophy Effortless handling of surfaces and meshes in each phase of the process chain The underlying Tebis hybrid technology lets you combine mesh surfaces (STL, FEM) and exact surfaces into any combination of element structures and further process them, for example when you have to digitize intermediate stages in the die manufacturing try-out process. Tebis makes it easy to generate exact surfaces from mesh surfaces, resulting in complete, high-quality surface models that other designers can further process. Feature technologies...

Open the catalog to page 6

Tebis prod uct philosophy Tebis machine simulation: High process safety and minimal lead times Manufacturing planners and NC programmers use the Tebis Simulator to clamp their components on virtual machines. They use it to image complete machining processes – long before the actual machining, and even for multiple NC machines. You can run virtual feasibility tests for your manufacturing department, provide support for job cost planning and increase process safety with visualization, testing and optimization of your manufacturing processes. The Tebis Simulator accesses a virtual machine...

Open the catalog to page 7

Tebis Autom ill™ Leverage knowledge with individual configuration options Tebis software was developed to allow processing of both unique special projects and repetitive standard jobs in a manufacturing compliant structured manner. If it turns out that certain CAD /CA M processes are repetitive, you can increase throughput time and process safety enormously if you save the methods you have tested in your CAD /CA M system and have them available as templates. Tebis will support you with individually configurable model templates, NC job lists and a variety of configuration databases. Model...

Open the catalog to page 8

Tebis Autom ill™ NC job lists In each model file, Tebis creates an NC job list in which all the NC machining steps are saved with all the necessary tools and all the area selections and parameter inputs. Toolpaths calculated on this basis will always retain their NC job reference and can be recalculated immediately after any changes to the parameters. Another advantage: NC job lists can be copied to components of similar type. The machining structure already worked out is thus quickly and easily copied to a different component, enormously reducing programming time. Configuration databases...

Open the catalog to page 9

“CAD plus CA M” technology ensures highest quality and flexibility in NC manufacturing Efficient production planning and scheduling is possible only if NC programmers also have powerful analysis and CAD functions. Production planners use Tebis stations to analyze imported data sets for problems and repair any problem areas quickly and precisely. Add-on, extension and protection surfaces are generated to enhance reliability and improve the quality of milling results, while the parts are structured according to cutting and stop surfaces. Tebis hybrid core supports surfaces, meshes and solids...

Open the catalog to page 11

Analyze design quality with the quality function. Analyze changes with the distance analysis function. Analyze fillets with the radius analyzer. Analyze undercut areas with the slope analyzer. Every Tebis workstation comes with a comprehensive range of useful functions and commands no matter which modules are installed: Wire frame model design: Do all design tasks necessary to create wire frame models. Create limiting and guide curves as well as auxiliary elements such as planes and axis systems in preparation for milling. Use edit functions to move, rotate, trim and limit existing curves...

Open the catalog to page 12All TEBIS catalogs and technical brochures

-

Tebis Viewer pages 8

8 Pages

-

Multiple setup

2 Pages

-

Tebis Viewer pages 2

2 Pages

-

5 Axis Trimming

4 Pages

-

DNC

4 Pages

-

Frontends01

4 Pages

-

Simulator

8 Pages

-

Lathe_A4_2011

6 Pages

-

Tebis_ProductRange

45 Pages

-

wire-edm

8 Pages

-

laser-cutting

4 Pages

-

TEBIS-FARO INTEGRATION

4 Pages

-

FEATURE DESIGN

8 Pages

-

ELECTRODE DESIGN

4 Pages

-

THE TEBIS BREP PRODUCT GROUP

12 Pages