Website:

TE CONNECTIVITY

Website:

TE CONNECTIVITY

Group: TE Connectivity

Catalog excerpts

PREMIUM QUALITY MANUFACTURING OF CRIMP CONNECTIONS TE APPLICATION TOOLING /// APPLICATORS

Open the catalog to page 1

PREMIUM QUALITY MANUFACTURING OF CRIMP CONNECTIONS Selecting the Applicator for Your Requirements SELECTION GUIDE OCEAN Applicator 2.0 - Mechanical • Wire range: 0.13 - 10.0 mm2 • Applicable for 90% of standard terminals • Available in Atlantic (w/male adapter) and Pacific (w/ female adapter) style formats to handle multiple press styles • Designed to handle the smallest terminals • Robust crimp height adjustment ring • Optimized crimper and anvil geometry Pneumatic Power OCEAN Applicator 2.0 - Pneumatic Cycle Counts • Wire range: 0.13 - 10.0 mm2 • Compact air feed design for easier fit...

Open the catalog to page 2

OCEAN 2.0 Applicator Facts and Features Chrome plated ram for improved lubricity, corrosion resistance, Robust fine adjust wire crimp height with range of 1.5 mm in increments of 0.01 mm Black nitriding for corrosion resistance, Large insulation crimp height adjustment range State-of-the-art crimper manufacturing for even tighter tolerances Precision machined strip Adjustable strip guide for precise each terminal Crimp Features – bell-mouth – cut-off – bend up / down Spring loaded terminal drag designed for easy loading/unloading DID YOU KNOW... Spare Tooling: Chrome plating, specialized...

Open the catalog to page 3

PREMIUM QUALITY MANUFACTURING OF CRIMP CONNECTIONS Choosing an Applicator OCEAN 2.0 Applicator Series The new OCEAN 2.0 applicator series was designed With the knowledge and experience of over a half specifically to exceed the requirements of today and century designing and manufacturing applicators and meet the demands of tomorrow. tooling, TE Connectivity (TE) has taken terminal crimping to a new level. Using the proven OCEAN applicator platform as a base, TE has developed the latest wave in applicator technology...the OCEAN 2.0 Applicator. TE has listened to customer input and market...

Open the catalog to page 4

Choosing an Applicator Standard Features on all OCEAN 2.0 Applicators One of the major design goals of the OCEAN 2.0 applicator series was increased flexibility. By giving the applicator the ability to flex between different terminator configurations it allows customers to quickly adapt their applicators to whatever configuration is needed. All parts to reconfigure the applicator are included and attachable to the unit for safe storage and quick access. As standard equipment the latest applicator will have all the accessories needed to switch between 30 and 40 mm stroke terminators,...

Open the catalog to page 5

PREMIUM QUALITY MANUFACTURING OF CRIMP CONNECTIONS OCEAN Applicator Facts and Features Two Terminal Feed Options Mechanical Feed The cam/follower design produces repeatable feed in the industry. Independent forward/backward adjustment. Standard Features • Significantly improved repeatability • Same feed module for side feed and end feed • Single tool adjustments • Infinite micro feed adjustment increments 1 revolution = 0.7 mm Advantages • Precise and repeatable terminal position over the anvil • Independent forward and back stroke adjustment • 50% faster adjustments compared to HDI/HDM...

Open the catalog to page 6

OCEAN 2.0 Applicator – Redesigned from the Bottom Up The OCEAN 2.0 applicator series includes several new features to aid in reliability and repeatable performance. To help prevent misalignment and during installation, the OCEAN 2.0 design includes a pinned baseplate. Standardization of adjustment and mounting screws reduces the number of tools needed to install and/or adjust an applicator. The OCEAN 2.0 line has been designed to reduce the number of unique tools needed to service, thereby shortening downtime and improving upon TE’s already impressive quick install rate. Standard Socket –...

Open the catalog to page 7

PREMIUM QUALITY MANUFACTURING OF CRIMP CONNECTIONS OCEAN 2.0 Applicator – Small Wire Crimping 0.22 mm2 / 24 AWG Applicators for small wire sizes the specification requirements for bell-mouth and Today’s miniaturized terminals demand a high quality cutoff tabs, which are commonly controlled with very applicator in order to meet the requirements of crimp small tolerances. specifications with very small tolerances. The TE Miniaturization of the connectors places higher OCEAN 2.0 applicator, with its improved ram align- demands on the processing machines. ment, fine adjust crimp height control...

Open the catalog to page 8

OCEAN Applicator – LITEALUM Wire Crimping Executive summary • e have developed a series of applicators that W • In parallel with LITEALUM terminal development, TE application tooling has been developing crimp tooling crimp all of the terminals released to date • We have met a number of challenges and have solutions to each • rimary goal: Keep the crimping process the same P • We continue to work on future improvements for crimping aluminum. TE is a terminal manufacturer with this goal, giving to our customers a major competitive advantage Unique applicator features of LITEALUM wire crimping...

Open the catalog to page 9

PREMIUM QUALITY MANUFACTURING OF CRIMP CONNECTIONS TE CrimpData App Our OCEAN applicator offering just got a whole lot more flexible thanks to TE CrimpData. With this mobile app you can manage applicator and spare parts inventory, and quickly verify that you have the right applicator for your terminal without having to run back to your desk. And it’s completely free to download from your smart phone or tablet’s app store! • et part numbers G of spare parts • et individual cycle S count of spare parts • oming soon C (order spare parts) What can it do? • eads the new data matrix bar-code R on...

Open the catalog to page 10

TE CrimpData App Manual Search Functionality Don’t have a QR code? No problem. Manually enter the serial or part number and search the database for applicator and terminal specs. Bar-code Scanner Click, scan and search with the touch of a button. The Right Tool for the Job TE CrimpData can help you quickly cross reference the applicator to your terminal and verify if it’s the right match. Order Parts Ready to check out? TE CrimpData allows you to find and order compatible spare tooling. (Coming soon) Sharing Tool Quickly launch your email to send order details to yourself or someone else....

Open the catalog to page 11All TE CONNECTIVITY catalogs and technical brochures

-

P280

4 Pages

-

HDMI CONNECTORS

2 Pages

-

LM

6 Pages

-

TTVF

9 Pages

-

TTP

6 Pages

-

SBP

9 Pages

-

T6112DS

5 Pages

-

HX-SCE

9 Pages

-

HLX-NEL

4 Pages

-

STD

8 Pages

-

TP.datasheet.pdf

10 Pages

-

SBP datasheet.pdf

9 Pages

-

ZHD-SCE

4 Pages

-

CM-SCE-TP Cable Marker

2 Pages

-

WP Gloss Whi Polyester Lab

7 Pages

-

LM, LE and LEB

6 Pages

-

T200 IDENT PRINTER

5 Pages

-

HL Cable Marker

3 Pages

-

STD and STB Markers

3 Pages

-

Catalog printer

2 Pages

-

Solar Identification Labels

6 Pages

Archived catalogs

-

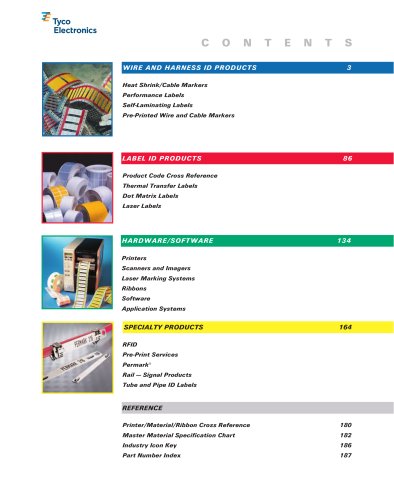

WIRE AND HARNESS ID PRODUCTS

85 Pages

-

RAYCHEM Tubing Products

24 Pages

-

PRINTERS

30 Pages

-

THERMAL TRANSFER LABELS

48 Pages

-

RFID

16 Pages

-

Thermal transfer ribbons

6 Pages

-

K Kapton® labels

2 Pages

-

Barcode Scanners

1 Pages