Catalog excerpts

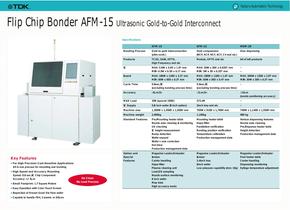

Specifications AFM-15AFM-22MDM-20Bonding Process Gold-to-gold interconnectionHeat compressionGlue dispensing(ultra sonic)(NCP, ACP, NCF, ACF, C4 and etc) Products TCXO, SAW, OPTO,Module, OPTO and etcAll of left productsHigh Frequency and etc IC MAX: 5.0W x 5.0D x 1.0T mmMAX: 30W x 30D x 0.635T mmΖMIN: 0.3W x 0.3D x 0.1T mmMIN: 3W x 3D x 0.25T mm Board MAX: 180W x 120D x 3.2T mmMAX: 180W x 120D x 1.6T mmMAX: 200W x 150D x 2.0T mmMIN: 50W x 50D x 0.3T mmMIN: 50W x 50D x 0.4T mmMIN: 30W x 30D x 0.3T mm Cycle Time 0.8sec/IC5.0sec/IC֖(excluding bonding process time)(excluding bonding process time) Accuracy 8 ѵ m/3 σ 3 ѵ m/3 σ 10 ѵ m(nozzle positioning accuracy) MAX Load 20N (special 100N) 372.4N IC Supply 5/6 inch wafer (8 inch option)2inch tray and etc֖ θ axis correctionHot blow Production management data Machine size Option and 1,200W x 1,450D x 1,550H mm 750W x 910D x 1,760H mm 740W x 1,140D x 1,550H mm Magazine Loader/UnloaderMagazine Loader/UnloaderMagazine Loader/Unloader Machine weight Special Features 2,000kg 1,100kg 680 kg IonizerIonizerPost heater table Carrier handling3.4inch trayCarrier handlingHepa-filter6inch waferDispensing monitoring Plasma cleaning unitLow pressure capability (min: 10g)Sylinge temperature adjustment Load/US sampling Nozzle surface monitoring 8 inch wafer Map data High accuracy mode Standard Features Pre/Mounting heater tableMounting heater tableVarious dispensing featuresNozzle auto cleaning & monitoringHepa-filterNozzle auto cleaning US checkingParallelism verificationPre/Dispense heater table IC height measurementBonding position verificationHeight detection Bump detectionTemperature calibrationProduction management data Wafer expandProduction management data Wafer > ? For High Precision Cost-Sensitive Applications All in one process for mounting and bonding? High Speed and Accuracy Mounting m? Small Footprint: Speed: 0.8 sec/IC Chip Component Accuracy: +/- 8 1.7 Square Meters? Easy Operation with Color Touch Screen? Inspection of Known Good Die from wafer? Capable to handle FR4, Ceramic or Silicon No CleanNo Lead Process >

Open the catalog to page 1All TDK Electronics Europe catalogs and technical brochures

-

PTC Thermistors

28 Pages

-

SATA SSD

3 Pages

-

CF CARD

3 Pages

-

Humidity Sensor CHS Series

11 Pages

-

Color Video Camera

2 Pages

-

EFE300M / EFE400M 300/400

4 Pages

-

Piezoelectric Receiver RU

2 Pages

-

Chip Beads STD

29 Pages

-

Piezoelectric Type LTS, TSP

9 Pages

-

Feed-back Type EFS

4 Pages

-

SMD NTCG

14 Pages

-

E Series

45 Pages

-

Multilayer/Q-up MLG0402Q

5 Pages

-

Pin Terminal Type PFC

14 Pages

-

Ferrite Magnets FB

27 Pages

-

NTC Thermistors SMD

14 Pages

-

Wound Type SMD Inductors (Coils)

12 Pages

-

Multilayer Chip Beads

27 Pages

-

TDK MLCC CATALOG b11

72 Pages

Archived catalogs

-

EMC and RF testing

4 Pages

-

Microwave Absorbers

16 Pages

-

RF Integrated Test Systems

12 Pages

-

Power supplies catalog

24 Pages

-

Planar Cores

8 Pages

-

Toroidal Cores

2 Pages

-

Ferrite Electrodes

4 Pages

![[BHF/BHP] Series for Barcode Printers, and Label Printers](https://img.directindustry.com/pdf/repository_di/34778/bhf-bhp-series-barcode-printers-label-printers-374455_1mg.jpg)