Catalog excerpts

Hydrostatic Speed Variator

Open the catalog to page 1

TB Wood’s is an industry leading designer and manufacturer of mechanical power transmission equipment for industrial control. Our mechanical product lines include: clutch and brake, synchronous and belted variable speed drives; grid, disc, jaw, gear coupling and elastomeric coupling products; sheaves and bushings. Registered trademarks include SureFlex®, Dura-Flex®, G-Flex®, and QT Bushings®. TB Wood’s was founded in 1857 and began as a foundry producing wood burning stoves. Our company’s tradition of product innovation started early. Wood’s entered the power transmission industry at the...

Open the catalog to page 2

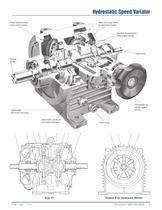

MACHINE SPECIFIC CONTROLS PRINCIPLE OF OPERATION Hydraulic Schematic The Hydrostatic Speed Variator is an integrated hydrostatic transmission consisting of a variable displacement radial piston pump drivCode 71 ing a fixed displacement radial piston motor. The pump-motor system is completely selfSynchronized Control contained within one case providing light NOT AVAILABLE The control synchronizes two speeds weight and ease of maintenance and (primary and secondary). Power factor serviceability. correction is substituted by this control. The Synchronizer Control is mainly The hydrostatic...

Open the catalog to page 4

HYDROSTATIC SPEED VARIATOR ACCESSORIES Hydrostatic Speed Variator The Hydrostatic Speed Variator is available with a wide variety of accessories and options that can extend and improve Main bearings rotate of the standard control mechanisms as well as monitor and control system loading. Fixedthe capabilities displacement radial piston motor Variable displacement radial piston pump HSV-A Code 0 Handwheel with Indicator Dial HSV & HSV-A Output Shaft Input shaft The gravity type indicator has a scale which reads the number of handwheel turns and fractions thereof. It allows an operator to set...

Open the catalog to page 5

PNEUMATIC PROPORTIONAL CONTROLS APPLICATIONS Applications HSV-A Code 52 Hydropneumatic Proportional Control (3-15 psi) Instrument air pressure at 3-15 psi is used to stroke this control from zero to the maximum speed. For CW rotation the control is mounted on the left; for CCW rotation the control is mounted on the right. Ideal for explosion-proof environments this control is sensitive, rugged and reliable. Simple in design, it has only one diaphragm and two springs. Note: Control for one direction only. Specify rotation direction. Code 53 Winding Hydropneumatic Proportional This control is...

Open the catalog to page 6

HSV VERSUS HSV-A OVERVIEW ELECTROHYDRAULIC REMOTE CONTROLS HSV Versus HSV-A Overview HSV HSV-A Feature Comparison HSV HSV-A Output HP Range 66 1/2 to 20 1/3 to 4 Code Relative Cost Higher Lower Electrohydraulic Control with two Housing Material speedsCast Iron Aluminum preset only Internal Gearing Not Available Optional Identical in function to the Code 65, this control operates only at one or the other of two preset speeds. Zeroing of the control is assured only if one of the ring nuts is set at zero speed. Input Options Shaft (T 10) NEMA C Top Mount Motor NOT AVAILABLE Output Options...

Open the catalog to page 7

ELECTRONIC REMOTE CONTROLS (ERC) RATINGS The ERC’s consist of a small motor driving a worm gear through a slip clutch to control the position of the eccentric ring in the variator. The slip clutch allows for a manual handwheel override and protects the small electric motor from stalling if over-controlled. The response time from zero to maximum speed is 14 seconds. The standard motor is a permanent split capacitor type. The position of the motor can be rotated around the axis of the handwheel. See notes below. 0.45 HP @ max. output speed with 1/2 HP electric motor .33 HP @ max output speed...

Open the catalog to page 8

A4 Code 37 Electronic Control This Electro-Hydraulic - Electronic proportional control provides a continuous speed adjustment by means of closed loop regulation. It will ensure speed stability even when there is a large variation in load. The control accepts a continuously changing reference signal and can provides adjustable acceleration and deceleration ramps. Speed regulation can be obtained using potentiometers or analog signals. The control uses an Electronic card with speed feedback 143TC Input & Output Std. sensor and proportional solenoid valve. 0.85 HP @ max. output speed with 1 HP...

Open the catalog to page 9

MANUAL CONTROLS RATINGS A8 Code 00 Standard Handwheel Control This is the standard control supplied with the HSV. It provides precise speed control in both directions and ease of operation. The number of turns from maximum reverse to forward and the operating torque is shown in the table below. 145TC Input & Output Std. 1.7 HP @ max. output speed with 2 HP electric motor Max. Output Speed (RPM) Running Torque (lb/ft) Gearbox ratio/model Weight (lbs) w/motor w/o motor 1.5 HP @ max output speed with 2 HP electric motor Gearbox ratio/model This lever control operates over 50 approxi195 150...

Open the catalog to page 10

MANUAL CONTROLS RATINGS A10 Code 03 Heavy Duty Lever Control This operates in the same manner as the Code 02 but is recommended for more frequent use. It is also available in a flanged version (Code 03F) to mount some other device such as a chain sprocket for example. 182TC Input & Output Std. 2.5 HP @ max. output speed with 3 HP electric motor Max. Output Speed (RPM) Running Torque (lb/ft) Gearbox ratio/model 2.0 HP @ max output speed with 3 HP electric motor Max. Speed Handwheel w/motor w/o motor Control (RPM) with Flexible Shaft Gearbox ratio/model Weight (lbs) w/motor w/o motor 279Code...

Open the catalog to page 11

RATINGS DIMENSIONS — HSV-A (IN.) 184TC Input & Output Std. 4 HP @ max. output speed with 5 HP electric motor HSVMax. B Model Output C Running Torque (lb/ft) 7.4 3.75 HP @ max output speed with 5 HP electric motor M NEMA Weight Weight (lbs) Frame lbs. P Running Speed Torque 3.27(RPM) 0.35 (ft. lbs.) 1.97 *NOTE: Denotes single, 11.08 1.125 reduction which 3.94 10.63 9.45 A12 19.32 5.88 triple, or quadruple 2.875 5.71 reverses the output shaft rotation. If single rotation control 9.67 check for proper 5.12 0.47 1.97 is used, 4.76 9.5 installation.

Open the catalog to page 12All TB Wood s Electronic - Woodsdrives.com catalogs and technical brochures

-

V-Belt Drives

231 Pages

-

ndustrial Couplings

12 Pages

-

Flexible Disc Couplings

52 Pages

-

Clutch Product Catalog

32 Pages

-

Belt Drives, Sheaves and Couplings

498 Pages

-

Premium V-Belt Drives Catalog

68 Pages