Catalog excerpts

Plastics Technology/ Electrical Engineering/ Adhesive Technology/ Dosing and Mixing Technology/ Fluid Technology SEALING AND ADHESION WITH GRAM ACCURACY TARTLER dosing mixing head enables high-precision processing of very small quantities Minimum-quantity dosing and application of small Own measurement technology on board quantities for multi-component plastics are key processes in many industrial assembly lines. These pro- In contrast to many other small quantity metering cesses are often at the heart of the action, especially systems on the market, the LV 2/2 from TARTLER in electrical and electronic encapsulation as well as in has its own measuring technology. Specifically, this adhesive and sealing technology. The TARTLER dosing means that it features an integrated load cell that mixing head LV 2/2 with integrated load cell is special- monitors both the mixing ratio and the shot weight ly designed for use in these areas. Low-viscosity mixtures can be applied with pinpoint accuracy in tiny shot quantities of 1.0 to 10 grams. Michelstadt, November 2020. – Although only introduced in the middle of last year, the TARTLER LV 2/2 dosing mixing head is already used in numerous industrial production processes. For example, it forms an important stage in the sealing of electronic components or the gluing of small magnets in the rotors of e-mobility drives. Here and in many other adhesive, sealing and encapsulation applications, it enables high-precision dosing and mixing of low-viscosity, self-flowing components made of silicone, polyurethane and epoxy as well as repeatable and accurate application in shot quantities from 1.0 to 10 grams. It is suitable as standard for processing resins and hardeners with viscosities from 50 to 20,000 mPas in mixing ratios of 100:5 to 100:200. Depending on the requirements and customer wishes, the LV 2/2 can also carry out many other specific mixing ratios. The output can be regulated from 5.0 to 100 ml/min. The LV 2/2 dosing mixing head from TARTLER is an intelligent precision system for the processing of small quantities of multi-component plastics.

Open the catalog to page 1

View of the four-color touch panel of the TARTLER LV2/2 dosing mixing head. The dosing mixing head LV 2/2 from TARTLER is suitable for series processing of resins and hardeners with viscosities from 50 to 20,000 mPas in mixing ratios from 100:5 to 100:200. during the application process. A major simplifica- also be used with the company‘s driven, rotating tion is that the load cell automatically self-calibra- disposable plastic mixers. This allows high-quality tes by working together with the Siemens control and homogeneous mixtures to be achieved even system and appropriate software. This...

Open the catalog to page 2

Up to four components In the standard version, the LV 2/2 is designed tion for resin processors who have to apply tiny for processing two components, but can also be amounts of liquid plastics, sealants and adhesives upgraded for dosing, mixing and application up in their production lines or in the laboratory, which to four components. In this way, TARTLER offers can be adapted to growing requirements. a high-quality and high-precision intelligent solu- TARTLER offers a range of additional modules to match its LV 2/2 dosing mixing head: A refill unit, a heating system, a material degassing...

Open the catalog to page 3All TARTLER GmbH catalogs and technical brochures

-

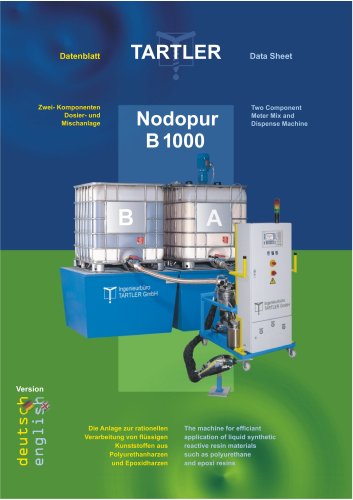

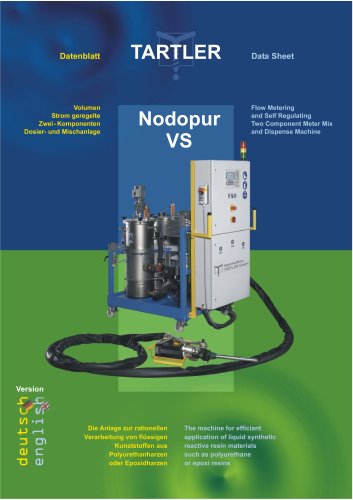

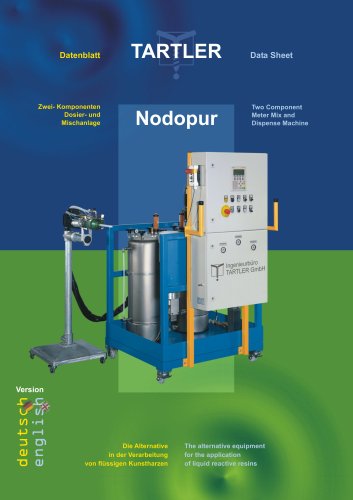

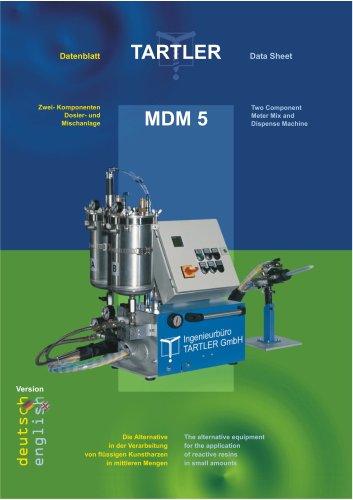

nodopur vs ar b 1000

2 Pages