Catalog excerpts

Association Espagnole de Manutention CERTIFICAT Accréditif de société associée à la FEM-AEM (Comité National de la FEM) FEDERATION MATERIALS

Open the catalog to page 1

Amenabar Chains

Open the catalog to page 2

Types of Chains Materials Shapes Geometry Thermal Treatment Coatings Calibration Test Chain Identification Material Reception Assembler Welder Ties Polish Zinc procedure Galvanization Deliveries Commercial Chain (Straight and Twisted) DIN-764 Chain Long-Link Chain Oval Chain DIN-766 Chain 6. Stainless Steel Chains AISI-316 ... p. 13 n Semi Long Link Chain, Degree-43 n DIN-5684 Chain, Degree-50

Open the catalog to page 3

The Chains Types of Chains The different types of chains are determined by the material, shape (straight, oval, twisted) and by the relationship among the placement, width and starting wire diameter. The manufacturing process can also distinguish the chain, whether it includes thermal treatments or not in order to improve the mechanical features or the coating, which provides high-resistance to oxidation/ rusting by improving its appearance. Materials Chains may be manufactured with the following materials: n carbon steel n alloyed steel n stainless steel Shapes n The most common chains are...

Open the catalog to page 4

Coatings Chains may be sold with three different finishings: n Black, the way they come out from the production line. n Polished, subject to a mechanical polishing process that improves its appearance while getting rid of the wire superficial debris. Besides, it gets rid of all the remaining borders that could have remained during the manufacturing process, but it does not give it any resistance to oxidation/ rusting. n Coated chemically treated through elements that protect the wire surface against oxidation/ rusting. The main coating of commercial chains is electrolytic galvanization, or...

Open the catalog to page 7

Manufacturing Process Material Reception Amenabars suppliers represent a fundamental part of our manufacturi ng process. That is why we select the best suppliers and we use the m 01 ost proper materials for each kind of product. Assembler In order to obtain a right chain, its necessary to properly configure the assembler. The development of each of the links is fundamental in order to avoid later alignment problems. The proper mechanical resistance of each of the links together with the right alignment of machinery and equipment make the link geometry perfect. Furthermore, its absolutely...

Open the catalog to page 8

Polish Polish provides a good appearance and allows the elimination of possible In Amenabar, due to the fact that quality is our rule, we polish all chains, even those that are later coated. sharpening that remains after the trim is made in the welding machine. Zinc Coating It provides resistance to oxidation/ rusting and it improves the chain appearance. Its quality depends on the thickness of the layer and on the covering of all the areas of the product to be coated. In Amenabar, we coat our chains with double thickness in comparison with our competitors (more than twice the time in...

Open the catalog to page 9

Degree-30-Chains Amenabars experience and know-how in the development and manufacturing of chains and elevation devices make our chains a synonym of security and quality, being the object of specification in several industries such as engineering, shipyards, siderurgy, fishing, etc. Amenabars Degree-30-Chains are manufactured with high technology machinery and with materials under Rules DIN-17115. Degree-30-Chains are manufactured under Rules DIN and each manufacturing lot is accepted after the satisfactory result of samples inspection. The specified loads in the tables are only theoretical...

Open the catalog to page 10

Test load Break. load Main use: continuous transportation, ceramic sewer devices and mining, plain roller and general uses. Class A: calibrated and tested (to be expressly specified in the order.) Class B: without calibration or testing (provided as standard.) In Class A chains, at request, and after placing our alveoli wheel or nut, Amenabar assures the perfect adjustment between the chain and the wheel thus issuing the corresponding test certificate. Test load Break. load Main use: industrial, agricultural, cattle, and general uses. Test load Break. load Applications principales :...

Open the catalog to page 11

Straight Link Chains Electrically welded Straight link chain for dogs Chain diameter in mm 2,5 3 Straight link chain for goats 3 Straight link chain for oxen 4 Other chains: splinter shaping, Dutch chains. Chain Accessories Round ring Number 1 2 3 Revolving, forged with or without ring t 25 30 35 40 45 50 60

Open the catalog to page 12

AISI-316 Stainless Steel Chains The AISI-316 stainless steel Amenabar chain Degree-43 and Degree-50 is manufactured with stainless austenitic material made of nickel-chrome-molybdenum and it is specially recommended for applications where hygiene is required as well as a high resistance to corrosion and high temperatures or use in high aggressive environments. The AISI-316 stainless steel Amenabar chain is obtained as a result of the combination of high technology machinery, the use of high quality materials and a strict quality assurance system in all production stages. This assures...

Open the catalog to page 13

Commercial Zinc-Coated Chain In Spools Commercial Zinc-Coated Chain In Spools Diameter d mm 2 2,5 3 4 5 6 7 8 9 10 The Most Comfortable Way Of Exposing Chains

Open the catalog to page 14

CNE Member from the EUROPEAN MAINTENANCE FEDERATION (FEM). Member of the Technical Committee of Resolution-58-Machinery from Elevation and Transport AENOR. Note: Amenabar reserves the right of modifying any contents of this catalog without previous notice.

Open the catalog to page 15

Amenabar Ctra. Ochandiano, s/n 01165 OLAETA - Alava Tel.: +34 - 945 45 00 50 Fax: +34 - 945 45 03 04 www.amenabar.net e-mail: amenabar@amenabar.ne

Open the catalog to page 16All TALLERES AMENABAR catalogs and technical brochures

-

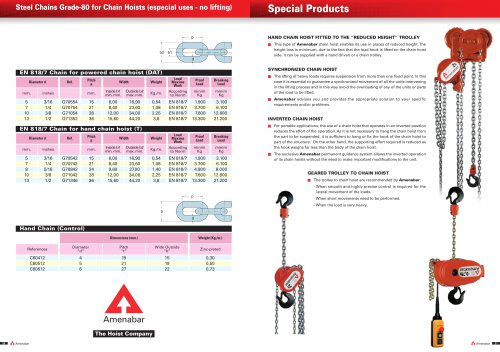

Amenabar Special Products

3 Pages

-

Amenabar Powered Chain Hoist

7 Pages

-

Amenabar Manual Trolleys

4 Pages

-

Amenabar Hand Chain Hoist

5 Pages