Website:

TA Instruments

Website:

TA Instruments

Group: Waters Corporation

Catalog excerpts

DISCOVER the WORLD’S FINEST THERMOMECHANICAL ANALYZER

Open the catalog to page 1

DISCOVER a TMA that delivers Superior Performance Unmatched Sensitivity Maximum Versatility

Open the catalog to page 2

Thermomechanical Analysis TA Instruments invites you to experience the finest in Thermomechanical Analyzers, the Discovery TMA 450. Discover the advanced engineering and attention to detail that provides enhancements in every aspect of performance and a new level of user experience. Featuring advanced testing capabilities and the widest range of fixtures, the Discovery TMA is sure to meet and exceed your expectations. It’s never been easier to get great TMA data! Features and Benefits: • Non-contact, friction-free motor delivers forces from 0.001 N to 2 N enabling measurements on the widest...

Open the catalog to page 3

Instrument Design Furnace TA Instruments’ engineering experience in design and integration of critical furnace, dimension measurement, and atmosphere-control components meld with powerful, flexible TRIOS software to ensure configuration flexibility and Sample Stage maximum versatility on the Discovery TMA 450. Furnace The TMA 450 features a highly-responsive low-mass furnace designed for the most precise control of temperature from -150°C to 1000°C and stable heating rates in the range of 0.1 to 100 °C/min. The furnace ensures the superior baseline performance required for accurate...

Open the catalog to page 4

Test Fixtures Expansion Expansion Expansion measurements determine a material’s coefficient of thermal expansion (CTE), glass transition temperature (Tg), and compression modulus. A flat-tipped standard expansion probe is placed on the sample (a small static force may be applied), and the sample is subjected to a temperature program. Probe movement records sample expansion or contraction. This test is used with most solid samples. The larger surface area of the macro-expansion probe facilitates analysis of soft or irregular samples, powders, and films, and the dilatometer fixture allows the...

Open the catalog to page 5

“APP Style” Touch Screen Touch Screen Features and Benefits: TA’s innovative touch screen, • Ergonomic design for enhanced accessibility and productivity making operation easier than ever with enhanced One-TouchAway™ functionality. • Packed with functionality to simplify instrument operation • Resilient, responsive touch screen for an enhanced user experience The One-Touch-Away™ interface includes: • Start/stop controls • Real-time signals and plot • Active method viewing • Temperature settings • Probe and force calibrations • Probe position and sample measurement settings • System...

Open the catalog to page 6

TRIOS Software TA Instruments' state-of-the-art software package uses cutting-edge technology for instrument control, data collection, and data analysis for thermal analysis and rheology. The intuitive user interface allows you to simply and effectively program experiments, and move easily between processing experiments and viewing and analyzing data. The Most VERSATILE CONTROL and ANALYSIS SOFTWARE! TRIOS Features: Control multiple instruments with a single PC and software package Overlay and compare results across techniques including TMA, DMA, DSC, TGA, SDT, and rheometers Unlimited...

Open the catalog to page 7

Thermomechanical analysis (TMA) measures material dimensional changes under controlled conditions of force, atmosphere, time and temperature. In the typical operation of a TMA, a small sample with parallel and flat surfaces is placed on a quartz stage near a thermocouple. A quartz probe is lowered against the specimen with a constant applied force. As the sample is heated or cooled, changes in dimension are measured by monitoring the motion of the quartz probe. Meeting and exceeding industry standards* for testing, the Discovery TMA 450 provides information about the material’s coefficient...

Open the catalog to page 8

Standard Tests The three most commonly used experiments are included on the Discovery TMA 450 as standard tests; these include the temperature ramp, force ramp and isostrain test templates. Coefficient of Thermal Expansion The most common property measured on a TMA is the coefficient of thermal expansion (CTE).The CTE describes the mechanical expansion or contraction of a material at different temperatures. It is an important property of a material, and negligence to take into account the effect temperature has on the physical size of materials has been known to cause product failures and...

Open the catalog to page 9

This example demonstrates the use of the expansion probe to accurately measure small CTE changes in an aluminum sample over a 200°C temperature range. TRIOS software permits analysis of the curve slope using a variety of methods to compute the CTE at a selected temperature or over a range. Point-to-Point Method α= 27.6 µm/m˚C Average Method α= 26.8 µm/m˚C Accurate Coefficient of Thermal Expansion Measurements Aluminum Expansion Probe Size: 7.62 µm Prog.: 5˚C/min Atm.: N2 Material Performance and Selection The figure to the left is an example of a 3-point bending test (flexure probe) plot...

Open the catalog to page 10

Stress/Strain Test Creep and Stress Relaxation Strain Stress Creep and Stress Relaxation Stress or strain is ramped, and the resulting strain or stress is measured at a constant temperature. Using customer-entered sample geometry factors, the data provides both stress/strain plots and related modulus information. In addition, calculated modulus can be displayed as a TMA can also measure viscoelastic properties using transient (creep or stress Strain / Stress Stress (Strain) Stress/Strain Tests relaxation) tests. In a creep experiment, input stress is held constant, and resulting strain is...

Open the catalog to page 11

TA's industry-leading Modulated TMATM efficiently separates simultaneous expansion and contraction in a material. Through deconvolution of the total dimensional change, an event such as the glass transition occurring in the same temperature region as stress relaxation is easily revealed. In Modulated TMATM (MTMATM), the sample experiences the combined effects of a sinusoidal temperature oscillation overlaid on the traditional linear ramp. The output signals (after Fourier transformation of the raw data) are total displacement and the change in thermal expansion coefficient. Modulated TMA...

Open the catalog to page 12All TA Instruments catalogs and technical brochures

-

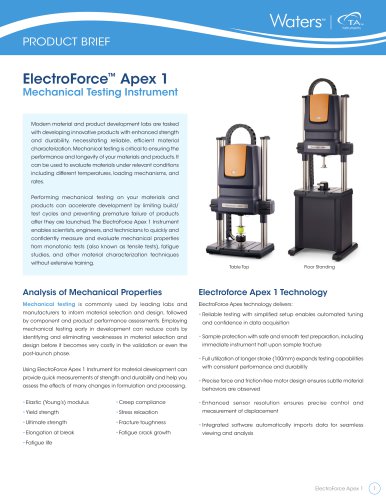

ElectroForce™ Apex 1

6 Pages

-

DCR_series

16 Pages

-

RSDSC-DSC-ITC

54 Pages

-

HEATING MICROSCOPE - HSML

2 Pages

-

HEATING MICROSCOPE - HSM

2 Pages

-

Broch DHR Accessories

73 Pages

-

Discovery SA

17 Pages

-

Discovery Hybrid Rheometer

23 Pages

-

DMA 3200 - High Force DMA

13 Pages

-

SDT

28 Pages

-

TGA

26 Pages

-

DILATOMETRY

13 Pages

-

ISOTHERMAL CALORIMETRY

34 Pages

-

MICROCALORIMETRY: ITC & DSC

44 Pages

-

VAPOR SORPTION ANALYSIS

8 Pages

-

RUBBER TESTING

19 Pages

-

RSA-G2 SOLIDS ANALYZER

28 Pages

-

DMA

23 Pages

-

Discover DSC SYSTEMS

20 Pages

-

RUBOTHERM SERIES DYNTHERM® TGA

22 Pages

-

IsoSORP®

13 Pages

-

BROCH-DSDT

28 Pages

-

HIGH PERFORMANCE TGA SYSTEMS

26 Pages

-

ARES-G2 RHEOMETER

36 Pages

-

AIR CHILLER SYSTEM

4 Pages

-

TAM AIR ISOTHERMAL CALORIMETRY

23 Pages

-

MICROCALORIMETRY: TAM IV & 48

48 Pages

-

Nano DSC and DSC Auto

14 Pages

-

ARES-G2 RHEOMETER

16 Pages

-

VTI-SA+

6 Pages

-

Discovery TGA Brochure

19 Pages

-

Discovery DSC Brochure

14 Pages

-

Microcalorimetry

60 Pages

-

Thermal Analysis

68 Pages

Archived catalogs

-

DILATOMETRY PUSH-ROD AND OPTICAL

23 Pages