Website:

TA Instruments

Website:

TA Instruments

Group: Waters Corporation

Catalog excerpts

New Castle, DE USA Lindon, UT USA Hullhorst, Germany Shanghai, China Beijing, China Tokyo, Japan Seoul, South Korea Taipei, Taiwan Bangalore, India Sydney, Australia Guangzhou, China Hong Kong Eschborn, Germany Wetzlar, Germany Brussels, Belgium Etten-Leur, Netherlands Paris, France Elstree, United Kingdom Barcelona, Spain Milano, Italy Warsaw, Poland Prague, Czech Republic Sollentuna, Sweden Helsinki, Finland Copenhagen, Denmark Chicago, IL USA Sao Paulo, Brazil Mexico City, Mexico Montreal, Canada

Open the catalog to page 2

RSA-G2 Solids Analyzer The new RSA-G2 is the most advanced platform for mechanical analysis of solids. The separate motor and transducer technology of the RSA-G2 ensures the purest mechanical data through independent control of deformation and measurement of stress. It is capable of performing the most accurate DMA measurements as well as many additional experiments including creep and recovery, stress relaxation, stress ramps, strain rate ramps, iso-strain, iso-force, fatigue, multiwave, arbitrary waveform, and dielectric thermal analysis. With such a broad range of solid analysis...

Open the catalog to page 3

theory DEFORMATION OF SOLIDS The RSA-G2 imposes a mechanical deformation to a specimen and measures the resulting stress response. The science concerned with the study of deformation and flow of materials is called rheology. Deformation is the relative change in shape of a body, or STRAIN, under the influence of an external force, or STRESS. Flow is a continuous relative change in shape per unit time, or STRAIN RATE, under influence of external STRESS. The RSA-G2 is in fact a linear rheometer, or a precision instrument, which contains a specimen of the material of interest in a geometric...

Open the catalog to page 4

• Phase Separation (Polymer Blends, Copolymers, ...) • Composites • Aging (physical or chemical) • Curing of Networks • Gelation • Cross-linking Reactions • Crosslink Density • Orientation Effects • Effects of Additives • Resiliency • Stress-strain Curves • Shrink Force • Mullins Effect • Dynamic Fatigue • Impact Strength • Toughness THE BENEFITS OF RHEOLOGY Solid and soft solid materials encounter a range of mechanical deformations (stresses and strains) over a wide variety of environmental conditions in practical daily use. This is important for nearly every industry, including aerospace,...

Open the catalog to page 5

specificationsRSA-G2 SOLIDS ANALYZER RSA-G2 SPECIFICATIONS Minimum Force Maximum Force Force Resolution Dynamic Displacement Range Displacement Resolution Modulus Range Modulus Precision Tan 8 Sensitivity Tan 8 Resolution Frequency Range Temperature Control Temperature Range Heating Rate Cooling Rate Isothermal Stability Note: Standard sample clamps are for use to a maximum temperature of 500°C. Optional sample clamps are required for testing to 600°C.

Open the catalog to page 6

The RSA-G2 Provides Independent Measurements of Stress and Strain When it comes to making the most accurate mechanical measurements, two heads are better than one! The mechanical behavior of solid polymers and other materials is described by material functions such as the modulus or compliance. The modulus is the ratio of stress to strain and the compliance is the ratio of strain to stress. In order to make the purest and most accurate viscoelastic measurements, it is best to measure the fundamental parameters of stress and strain independently. This approach, taken by the TA Instruments...

Open the catalog to page 8

RSA-G2 Design Advantage At the heart of the RSA-G2 dual-head solids analyzer is the high performance drive motor and unique transducer. The sample is deformed from the bottom by a direct-drive DC-Servo motor featuring all new electronic DSP control. The force generated in the sample is measured at the top by the patented Force Rebalance Transducer(FRT). The RSA-G2 FRT incorporates a highly sensitive position sensor and linear motor with temperature-compensated rare-earth magnets to ensure the most accurate force measurements.The FRT directly measures sample force from the current required...

Open the catalog to page 9

Temperature Control Temperature and environment control for the RSA-G2 is provided by the new Forced Convection Oven, FCO. The FCO is an air/N2 gas convection oven designed for optimum temperature stability, extremely rapid heating and cooling, and ease of use over the temperature range of -150 to 600 °C. The maximum controlled heating rate is 60 °C/min. Obtaining the -150 °C minimum temperature requires an optional liquid nitrogen-cooling device. Alternatively, an optional mechanical cooling is possible down to a minimum temperature of -80 °C. Superior temperature stability is achieved...

Open the catalog to page 10

High-Speed Electronics and Data Processing The RSA-G2 is equipped with new high-speed electronics with digital signal processing for transducer measurements and motor control. While many manufacturers cut costs by combining the test station and electronics into a single box, the separate electronics approach of TA Instruments RSA-G2 isolates the precision measurements from heat and vibration. This approach ensures the best sensitivity and data quality from the test station.The electronics enable fully integrated high-speed data acquisition for transient (up to 8000Hz) and oscillation (up to...

Open the catalog to page 11

RSA-G2 Clamping Systems The RSA-G2 features a variety of sample clamps that provide multiple modes of deformation to accommodate a wide range of sample stiffness.The RSA-G2 can easily characterize films, fibers, soft foams, pressure sensitive adhesives (PSA), thermoplastic or thermoset bar sam ples, high modulus composites, metals, and even medium to high viscosity polymer melts in shear sandwich. All sample clamps are constructed from 17-4 PH steel for maximum rigidity. Standard sample clamps are for use to a maximum temperature of 500 °C. Optional stainless steel sample clamps required...

Open the catalog to page 12

Dual and Single Cantilever Cantilever modes are also known as “clamped” or “supported” bending modes because the support and deformation points are mechanically fixed to the sample. In dual cantilever the sample is clamped at both ends and at the center. The same clamp is used for single cantilever and the sample is clamped between one end and the central clamp. Single cantilever allows for testing of shorter sample lengths. Cantilever is ideal for general-purpose testing of thermoplastics and elastomers and other highly damped materials, as well as measuring transitions of coatings on...

Open the catalog to page 13All TA Instruments catalogs and technical brochures

-

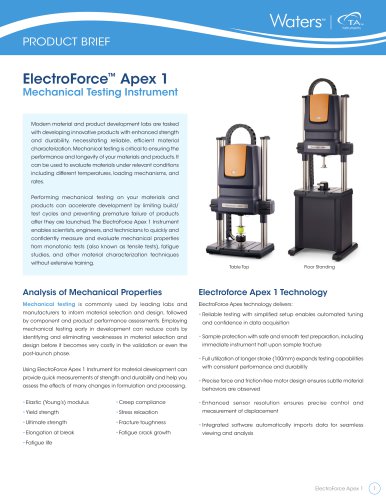

ElectroForce™ Apex 1

6 Pages

-

DCR_series

16 Pages

-

RSDSC-DSC-ITC

54 Pages

-

HEATING MICROSCOPE - HSML

2 Pages

-

HEATING MICROSCOPE - HSM

2 Pages

-

Broch DHR Accessories

73 Pages

-

Discovery SA

17 Pages

-

Discovery Hybrid Rheometer

23 Pages

-

DMA 3200 - High Force DMA

13 Pages

-

SDT

28 Pages

-

TGA

26 Pages

-

DILATOMETRY

13 Pages

-

ISOTHERMAL CALORIMETRY

34 Pages

-

MICROCALORIMETRY: ITC & DSC

44 Pages

-

TMA

15 Pages

-

VAPOR SORPTION ANALYSIS

8 Pages

-

RUBBER TESTING

19 Pages

-

DMA

23 Pages

-

Discover DSC SYSTEMS

20 Pages

-

RUBOTHERM SERIES DYNTHERM® TGA

22 Pages

-

IsoSORP®

13 Pages

-

BROCH-DSDT

28 Pages

-

HIGH PERFORMANCE TGA SYSTEMS

26 Pages

-

ARES-G2 RHEOMETER

36 Pages

-

AIR CHILLER SYSTEM

4 Pages

-

TAM AIR ISOTHERMAL CALORIMETRY

23 Pages

-

MICROCALORIMETRY: TAM IV & 48

48 Pages

-

Nano DSC and DSC Auto

14 Pages

-

ARES-G2 RHEOMETER

16 Pages

-

VTI-SA+

6 Pages

-

Discovery TGA Brochure

19 Pages

-

Discovery DSC Brochure

14 Pages

-

Microcalorimetry

60 Pages

-

Thermal Analysis

68 Pages

Archived catalogs

-

DILATOMETRY PUSH-ROD AND OPTICAL

23 Pages