Website:

TA Instruments

Website:

TA Instruments

Group: Waters Corporation

Catalog excerpts

HIGH FORCE DMA AND FATIGUE ELECTROFORCE® DMA 3200

Open the catalog to page 1

Materials encounter a range of mechanical loads and deformations (stresses and strains) over a wide variety of environmental conditions in practical daily use. Therefore, for most applications in nearly every industry, including aerospace, medical devices, asphalt, automotive, electronics, biomaterials, elastomers, composites, food, etc., mechanical properties are often considered the most important of all physical and chemical properties of materials. The increasing demands for high-quality, high-performing products make it vitally important to understand the complex viscoelastic...

Open the catalog to page 2

HIGH FORCE DMA & FATIGUE DMA 3200 The DMA 3200 combines decades of cutting-edge fatigue and world-leading Dynamic Mechanical Analysis technologies into a unique and highly versatile testing platform. The patented frictionless ElectroForce® motor technology, superior mechanical design, efficient TESTING VERSATILITY in a SINGLE INSTRUMENT that delivers INDUSTRY-LEADING DMA and FATIGUE TESTING CAPABILITIES environmental control, and wide variety of clamping systems deliver superior data accuracy for the broadest • Patented, linear motor and high-resolution displacement sensor provide unmatched...

Open the catalog to page 3

Indicator Light Test Specimen ElectroForce® Linear Motor at high speeds. The sensor is placed close to the sample and loading axis to performance and data accuracy. This unique motor further minimize errors in compliance or thermal expansion. technology combines powerful rare-earth magnets with a frictionless flexural suspension for the most precise force and Flexural Suspension Interchangeable Force Sensors Moving Magnets High-stiffness and high-bandwidth force sensors are mounted on the base of the rigid frame and are interchangeable for flexibility in test ranges. The instrument up to...

Open the catalog to page 4

ENVIRONMENTAL SYSTEMS TECHNOLOGY The DMA 3200 can be configured with one of two environmental systems offering the flexibility Air Chiller Systems offer unique gas flow cooling that provides for to meet a wide variety of testing requirements. sub-ambient testing without the use of liquid nitrogen. Available in two models, the ACS-2 and ACS-3, the chillers feature a multi- Both offer a variety of clamping systems, and stage cascading compressor design that is capable of utilizing are compatible with TA’s Air Chiller Systems with compressed air (7 bar, 200 l/min) as the cooling medium. The...

Open the catalog to page 5

CLAMPING SYSTEMS TECHNOLOGY The DMA 3200 features a variety of sample clamping systems that provide multiple modes of deformation to accommodate a wide range of sample stiffness. Standard clamping systems available for use with the FCO include tension, compression, three-point bending, clamped bending, and shear sandwich. Standard FCO clamps, constructed of 17-4 stainless steel, are for use to a maximum In this mode, the sample is clamped at the top and bottom and placed in tension. The tension clamp is for temperature of 500 °C, with optional clamps available for extended use to 600 °C....

Open the catalog to page 6

Dual and Single Cantilever Cantilever modes are also known as "clamped" or "supported" bending modes because the support and deformation points are mechanically fixed to the sample. In dual cantilever, the sample is clamped at both ends and at the center. The same clamp is used for single cantilever and the sample is clamped between one end and the central clamp. Single cantilever allows for testing of shorter sample lengths. Cantilever is ideal for general-purpose testing of thermoplastics and elastomers and other highly damped materials, as well as measuring transitions of coatings on...

Open the catalog to page 7

CONTROL AND ANALYSIS SOFTWARE TECHNOLOGY TRIOS for Data Analysis Software most powerful software packages: WinTest® and TA Instruments TRIOS software seamlessly transfers DMA data from WinTest, providing experimentalists with the industry’s leading tool for analyzing and presenting DMA data. This intuitive TRIOS. These two packages provide advanced algorithms, sophisticated data visualization, software includes a wide variety of plotting tools, some of which include multi-axis plotting, smart default and user-customizable graph settings, drag-and-drop overlay, and user-defined variables. A...

Open the catalog to page 8

DMA 3200 APPLICATIONS Polycarbonate Temperature Ramp in Tension Dynamic Mechanical Analysis, DMA to determine a variety of mechanical properties, i.e., complex modulus, E*, storage and loss and enables testing of larger samples or actual components. Examples of high moduli (E’, & E”) and damping (tan δ) of viscoelastic materials, detect molecular motions, and force DMA capabilities are shown in the figures to the right. develop structure-property relationships. The top figure shows a temperature ramp on a bar of Polycarbonate at a heating Material Properties: Typical Applications: • Glass...

Open the catalog to page 9

DMA 3200 APPLICATIONS Tensile Fatigue Test on Solder Fatigue and Quasi-Static Testing Most materials, components, and devices are exposed to repeated loading conditions during changes in material behavior, which can impact overall performance, or it can result in complete and catastrophic failure. Mechanical fatigue testing provides insights on how and Enabling Fatigue and Quasi-Static Testing The flexibility, power, and durability of the DMA 3200 enable a variety of tests in when materials, components, or devices fail when subjected to oscillating forces, or stresses. addition to DMA. Its...

Open the catalog to page 10

* Note: Standard sample clamps are for use to a maximum temperature of 500 °C. Optional sample clamps are required for testing to 600 °C.

Open the catalog to page 11

New Castle, DE USA Lindon, UT USA Wakefield, MA USA Eden Prairie, MN USA Chicago, IL USA Costa Mesa, CA USA Montreal, Canada Toronto, Canada Mexico City, Mexico Sao Paulo, Brazil Hullhorst, Germany Bochum, Germany Eschborn, Germany Wetzlar, Germany Elstree, United Kingdom Brussels, Belgium Etten-Leur, Netherlands Paris, France Barcelona, Spain Milano, Italy Warsaw, Poland Prague, Czech Republic Sollentuna, Sweden Copenhagen, Denmark Shanghai, China Beijing, China Tokyo, Japan Seoul, South Korea Taipei, Taiwan Guangzhou, China Petaling Jaya, Malaysia Singapore Bangalore, India Sydney,...

Open the catalog to page 12All TA Instruments catalogs and technical brochures

-

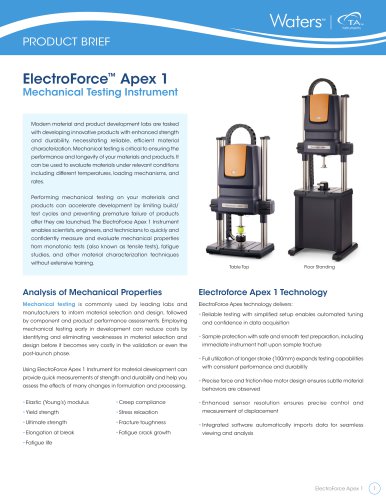

ElectroForce™ Apex 1

6 Pages

-

DCR_series

16 Pages

-

RSDSC-DSC-ITC

54 Pages

-

HEATING MICROSCOPE - HSML

2 Pages

-

HEATING MICROSCOPE - HSM

2 Pages

-

Broch DHR Accessories

73 Pages

-

Discovery SA

17 Pages

-

Discovery Hybrid Rheometer

23 Pages

-

SDT

28 Pages

-

TGA

26 Pages

-

DILATOMETRY

13 Pages

-

ISOTHERMAL CALORIMETRY

34 Pages

-

MICROCALORIMETRY: ITC & DSC

44 Pages

-

TMA

15 Pages

-

VAPOR SORPTION ANALYSIS

8 Pages

-

RUBBER TESTING

19 Pages

-

RSA-G2 SOLIDS ANALYZER

28 Pages

-

DMA

23 Pages

-

Discover DSC SYSTEMS

20 Pages

-

RUBOTHERM SERIES DYNTHERM® TGA

22 Pages

-

IsoSORP®

13 Pages

-

BROCH-DSDT

28 Pages

-

HIGH PERFORMANCE TGA SYSTEMS

26 Pages

-

ARES-G2 RHEOMETER

36 Pages

-

AIR CHILLER SYSTEM

4 Pages

-

TAM AIR ISOTHERMAL CALORIMETRY

23 Pages

-

MICROCALORIMETRY: TAM IV & 48

48 Pages

-

Nano DSC and DSC Auto

14 Pages

-

ARES-G2 RHEOMETER

16 Pages

-

VTI-SA+

6 Pages

-

Discovery TGA Brochure

19 Pages

-

Discovery DSC Brochure

14 Pages

-

Microcalorimetry

60 Pages

-

Thermal Analysis

68 Pages

Archived catalogs

-

DILATOMETRY PUSH-ROD AND OPTICAL

23 Pages