Website:

TA Instruments

Website:

TA Instruments

Group: Waters Corporation

Catalog excerpts

New Castle, DE USA Lindon, UT USA Hullhorst, Germany Shanghai, China Beijing, China Tokyo, Japan Seoul, South Korea Taipei, Taiwan Bangalore, India Sydney, Australia Guangzhou, China Hong Kong Eschborn, Germany Brussels, Belgium Etten-Leur, Netherlands Paris, France Elstree, United Kingdom Barcelona, Spain Milano, Italy Warsaw, Poland Prague, Czech Republic Sollentuna, Sweden Helsinki, Finland Copenhagen, Denmark Chicago, IL USA Sao Paulo, Brazil Mexico City, Mexico Montreal, Canada

Open the catalog to page 2

dilatometry Every TA Instruments dilatometer precisely measures dimensional changes of a specimen brought about by changes in its thermal environment. Typical measurements include thermal expansion, annealing studies, determination of phase transitions and the glass transition, softening points, kinetics studies, construction of phase diagrams and sintering studies, including the determination of sintering temperature, sintering step and rate-controlled sintering. Investigation of processing parameters as reflected by dimensional changes of the material can be studied in great detail...

Open the catalog to page 4

dilatometer DIL 805 In the heat treatment of metal alloys, the heating rate, quenching rate and isothermal dwell times are important parameters that dictate the final crystalline structure and the resultant physical properties. These microstructural changes may be observed through process simulation with real-time monitoring of dimensional change. Among other things, measurements of distinct alloy compositions are used to create time-temperaturetransformation diagrams (TTT) and continuous-coolingtransformation diagrams (CCT), which are critical in process design and optimization. The DIL...

Open the catalog to page 5

(dependent on sample material) -150 °C to 1300 °C

Open the catalog to page 6

quenching dilatometer DIL 805 ACCESSORIES 805L Quenching Dilatometer The DIL 805L is a fully automated self-contained quenching dilatometer used to observe dimensional changes under extreme conditions of controlled heating and cooling. A solid or hollow sample is inductively heated to a temperature plateau and is then continuously cooled at a user-defined (linear or exponential) cooling rate. The phase transformation occurring in the continuous cooling process or in the isothermal dwell (which may also be a multistep transition) is indicated by the measured change in length. An array of...

Open the catalog to page 7

805D Deformation Dilatometer Steel processes, such as hot or cold rolling, require detailed knowledge of the time-temperature-transformation diagram after deformation (DTTT diagram). With the deformation module, the principle of the 805A quenching dilatometer is extended to include controlled deformation. Solid samples are compressed using various deformation programs (e.g. linear, multi-level with a constant deformation force or rate) with controlled forces up to 25 kN or rates up to 200 mm/s. An unlimited number of deformation steps can be performed with a pause between steps of only 40...

Open the catalog to page 8

quenching dilatometer DIL 805 ACCESSORIES Alpha Measuring System The Alpha measuring head uses low-expansion fused silica components in conjunction with a true differential LVDT for high-precision expansion measurements. This system allows the DIL 805 to be used for traditional push-rod dilatometer studies such as the determination of the coefficient of thermal expansion (CTE) and the softening point. DTA/DSC Measuring Head The DTA/DSC measuring head is custom-designed for the analysis of phase transformation and precipitation processes in metals. With heating and cooling rates of up to 500...

Open the catalog to page 9

Induction Heating Coil The custom-designed induction heating coil allows for rapid inductive heating at rates up to 4000 K/s of an electrically conductive solid or hollow sample. During a test, only the sample is heated so there is no associated furnace/insulation cool-down period, and another sample can be loaded immediately upon test completion. The hollow-core inner coil also serves as the purge gas conduit focused at the heating zone, ensuring an inert environment throughout the test. Specially designed heating rings are also available for use with samples that are not electrically...

Open the catalog to page 10

dilatometer APPLICATIONS Steel Phase Transformation Phase transformations in steel are highly path dependent, reflecting the effects of earlier processing steps on subsequent phase composition. The transitions between different phases of steel are especially clear when measured by the DIL 805A Quenching Dilatometer, and the temperatures at which they occur are critical in the construction of the TTT and CCT diagrams. In this example, the first ramp rate heats the sample above its austenitic temperature, at which time it is quenched. The plot shows the start (Ar3) and finish (Ar1) of the...

Open the catalog to page 11

The 805D add-on module can precisely control the strain-rate of a sample and measure the resultant force required to achieve this. In this high speed test run, a deformation rate of 10 mm/s is used for a maximum displacement of 5 mm (Strain 0.50). The force exerted by the hydraulic ram is closely monitored, and both data sets can be used to plot the true processing for repeatable production of steel with the desired physical properties. contraction and phase transformation is measured. Using this measured data, the manufacturer can streamline their 1 mm deformation. After another 10 s dwell...

Open the catalog to page 12

© 2013 TA Instruments. All rights reserved.

Open the catalog to page 13All TA Instruments catalogs and technical brochures

-

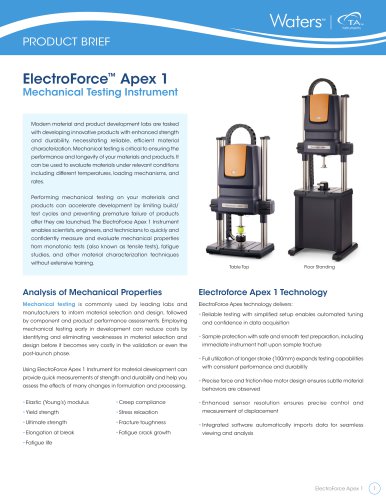

ElectroForce™ Apex 1

6 Pages

-

DCR_series

16 Pages

-

RSDSC-DSC-ITC

54 Pages

-

HEATING MICROSCOPE - HSML

2 Pages

-

HEATING MICROSCOPE - HSM

2 Pages

-

Broch DHR Accessories

73 Pages

-

Discovery SA

17 Pages

-

Discovery Hybrid Rheometer

23 Pages

-

DMA 3200 - High Force DMA

13 Pages

-

SDT

28 Pages

-

TGA

26 Pages

-

ISOTHERMAL CALORIMETRY

34 Pages

-

MICROCALORIMETRY: ITC & DSC

44 Pages

-

TMA

15 Pages

-

VAPOR SORPTION ANALYSIS

8 Pages

-

RUBBER TESTING

19 Pages

-

RSA-G2 SOLIDS ANALYZER

28 Pages

-

DMA

23 Pages

-

Discover DSC SYSTEMS

20 Pages

-

RUBOTHERM SERIES DYNTHERM® TGA

22 Pages

-

IsoSORP®

13 Pages

-

BROCH-DSDT

28 Pages

-

HIGH PERFORMANCE TGA SYSTEMS

26 Pages

-

ARES-G2 RHEOMETER

36 Pages

-

AIR CHILLER SYSTEM

4 Pages

-

TAM AIR ISOTHERMAL CALORIMETRY

23 Pages

-

MICROCALORIMETRY: TAM IV & 48

48 Pages

-

Nano DSC and DSC Auto

14 Pages

-

ARES-G2 RHEOMETER

16 Pages

-

VTI-SA+

6 Pages

-

Discovery TGA Brochure

19 Pages

-

Discovery DSC Brochure

14 Pages

-

Microcalorimetry

60 Pages

-

Thermal Analysis

68 Pages

Archived catalogs

-

DILATOMETRY PUSH-ROD AND OPTICAL

23 Pages