Catalog excerpts

Opti-Stack Automated Stacking Systems Opti-Stack 3000 Vack Opti-Stack 3000 Opti-Stack 6000 Vack Opti-Stack 6000 Optimization of staff and wood resources

Open the catalog to page 1

- Opti-Stack 3000 and 6000 Automated stacking systems System TM offers a wide range of standard, well-proven automated handling systems for the automation of main machines such as: Opti-Stack 3000 Vack Opti-Stack 3000 Cross-cut saw Double-end tenoner Opti-Stack 6000 Vack Opti-Stack 6000 Opti-Stack solution Technical data Additional products System TM service The automated stacking systems are designed to dramatically increase the capacity of the main machine and to reduce labor costs. With System TM’s Opti-Stack series we are able to advise you on - and supply - the right solution to fulfil...

Open the catalog to page 2

Opti-Stack 3000 Vack Automated stacking system - Opti-Stack 3000 Vack Opti-Stack 3000 Vack is a vacuum stacking unit which is able to stack complete or partial layers of workpieces after different main machines such as cross-cut saws, moulding machines, double-end tenoners, resaws and sanding machines. The Opti-Stack 3000 Vack consist of two vacuum heads, suitable for stacking short workpieces from 380 – 2,500 mm (15”- 98”) at a capacity of up to 5 layers per minute by random or uniform lengths. The vacuum head consist of check valves technology which automatically recognizes and closes the...

Open the catalog to page 3

Automated stacking system - Opti-Stack 3000 The Opti-Stack 3000 is a mechanical high-performance stacking system, designed to stack short workpieces from 3802,500 mm (15" - 98"), at a capacity of up to 150 workpieces or 12 layers per minute by uniform lengths. Based on a standard module, the stacker has a modular design that can be customized to meet your exact requirements for the stacking of workpieces after different main machines such as moulders, double-end tenoners, cross-cut saws and resaws. The mechanical stacking system can be equipped with optional features such as stick...

Open the catalog to page 4

Opti-Stack 6000 Vack Automated stacking system - Opti-Stack 6000 Vack Opti-Stack 6000 Vack is a vacuum stacking unit which is able to stack complete or partial layers of workpieces from different main machines such as cross-cut saws, moulding machines, double-end tenoners, resaws and sanding machines. The Opti-Stack 6000 Vack consists of an adjustable number of vacuum heads, customized to match all stacking requirements. The stacking unit is suitable for stacking long workpieces from 1,200 – 6,300 mm (3’- 21’) at a capacity of up to 4 layers per minute, by random or uniform lengths and...

Open the catalog to page 5

Opti-Stack 6000 Automated stacking system - Opti-Stack 6000 The Opti-Stack 6000 is designed to stack workpieces from different main machines such as for example cross-cut saws, moulding machines, resaws and rip saws. The Opti-Stack 6000 is a high-performance mechanical stacking system and is designed to stack long workpieces from 1,200 – 6,300 mm (3’- 21’). The capacity of the Opti-Stack 6000 is up to 6 layers per minute by random or uniform lengths and widths. Packs can easily and automatically be replaced during operation - without stopping the main machinery. The mechanical stacking...

Open the catalog to page 6

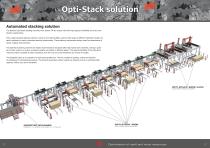

Opti-Stack solution Automated stacking solution The standard Opti-Stack stacking machines from System TM are unique with their high degree of flexibility and many combination opportunities. Every single standard stacking machine consist of very high flexibility, and the wide range of different Opti-Stack models are easily combined to match customized stacking requirements. These stacking requirements always meet the expectations of layout, capacity and processes. The Opti-Stack stacking machines are highly recommended to be placed after high-speed main machines, making it possible to stack...

Open the catalog to page 7

Overview of the data for Opti-Stack series All of the above data can be customized upon request Optimization of staff and wood resources

Open the catalog to page 8

Additional products System TM A/S All products and system solutions from System TM can be equipped with an automatic handling or scanning system for best lumber utilization and capacity, with a minimum use of labor power. In order to meet all customer demands, our range of material handling systems consist of both standard and fully customized system solutions. All products and system solutions from System TM can be equipped with an automatic scanning system for best lumber utilization and production optimization. The scanner partner of System TM is a technology leader within the scanning...

Open the catalog to page 9

System TM service System TM service is a key strategic business unit. The service department focuses on providing you with service and support and we continuously develop our services to meet your requirements. System TM service offers you services to ensure uninterrupted operation, with the best possible productivity and utilization. Systematic maintenance minimizes production downtimes, and ensures smooth operation with minimum risk of unexpected events. System TM service is a team of professionally educated, trained and experienced service engineers and technicians ready to provide full...

Open the catalog to page 10

System TM A/S Skovdalsvej 35, P.O. Box 249 DK-8300 Odder, Denmark *System TM cannot be held responsible for any misprints or omissions Optimization of staff and wood resources

Open the catalog to page 11All System TM catalogs and technical brochures

-

Opti-Feed

11 Pages

-

Opti-Kap

13 Pages

-

Opti-Solutions

13 Pages

-

Opti-Joint H-200

11 Pages