Catalog excerpts

Opti-Solutions Customized system solutions Optimization of staff and wood resources

Open the catalog to page 1

Customized system solutions Customized system solutions Customized system solutions Total Supplier We are experts in combining different main machines with material handling, giving our customers highly integrated and fully optimized lines with regards to capacity, yield and staff resources. The success of our business is based on our understanding of the customer’s needs, while creative use of knowledge and technology forms the foundation of our core competencies. Opti-Solutions are characterized by: One total supplier Individually designed and manufactured with regards to capacities,...

Open the catalog to page 2

Total supplier System TM as your total supplier When choosing System TM as your total supplier you will benefit from the vast experience of our entire team. System TM takes full responsibility for the entire process, and will be your only supplier when you invest in a single system or an entire system solution. The competencies of System TM covers everything from line design, installation, commissioning and staff training to service and maintenance - all to make your production as efficient as possible. With our technical expertise and experience, we can advise you on all technical aspects...

Open the catalog to page 3

Door manufacturer SCANNER Detection of defects and quality OPTI-KAP 5003 Optimizing cross-cut saw SORTING BELTS Automated feeding system Automated stacking system FINGER JOINT This Opti-Solution is an optimizing cross-cut line consisting of an Opti-Feed 6000 automatic feeding system that destacks, separates and turns the workpieces before a ripsaw. Production: Doors The ripsaw splits the workpieces before a moulder that calibrates the top and bottom surface for an optimal scanning detection. Two Opti-Kap 5003 cross-cut saws cuts the wood according to the scanning result for the best wood...

Open the catalog to page 4

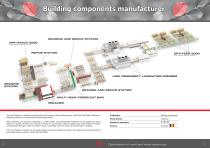

Building components manufacturer GRADING AND REPAIR STATION OPTI-STACK 6000 Automated stacking system REPAIR STATION OPTI-FEED 6000 Automated feeding system HIGH FREQUENCY LAMINATING PRESSES GRADING STATION GRADING AND REPAIR STATION MULTI HEAD CROSS-CUT SAW MOULDER This Opti-Solution is a material handling system that consists of four feeding systems, model Opti-Feed 6000, feeding four different qualities to two high frequency laminating presses. After laminating, the beams are separated in a buffer system and automatically transported to two grading and repair stations. If needed, the...

Open the catalog to page 5

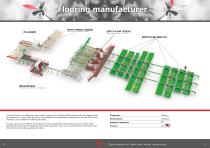

Flooring manufacturer PLANER OPTI-FEED 6000 Automated feeding system OPTI-KAP 5003 Optimizing cross-cut saw SORTING BELTS Detection of defects and quality This Opti-Solution is an optimizing cross-cut line consisting of an Opti-Feed 6000 feeding system, that feeds batches of workpieces to a planer. After the planer, the workpieces are automatically transported to a Microtec 502 scanner including x-ray, for detection of defects and quality. Through a queue control system, the workpieces are then transported to three optimizing cross-cut saws model Opti-Kap 5003, that cuts the workpieces into...

Open the catalog to page 6

Moulding & millwork manufacturer MOULDER DOUBLE-END TENONER OPTI-STACK 6000 Automated stacking system FOLIO MACHINE BANDSAW OPTI-FEED 6000 Automated feeding system STRAPPING MACHINES This Opti-Solution is a material handling system consisting of an automatic infeed system model Opti-Feed 6000, that automatically feeds the workpieces to a bandsaw. The bandsaw splits the workpieces into two or three pieces, and the workpieces are subsequently singulated and orientated in the correct order before entering a moulder. After the moulding process, the workpieces are transported to a double-end...

Open the catalog to page 7

Pallet manufacturer MULTI HEAD CROSS-CUT SAW OPTI-STACK 6000 Automated stacking system OPTI-FEED 6000 Automated feeding system This Opti-Solution is a multi head cross-cut line consisting of an automatic infeed system model Opti-Feed 6000, that automatically feeds the workpieces to a feeding chain conveyor. Production: Pallet The feeding chain conveyor creates layers of the workpieces, and feed the layers into a multi head cross-cut saw model MK5, for multiple cross-cutting. The cross-cut workpieces are then transported to a continuous stacking machine model Opti-Stack 6000, also capable of...

Open the catalog to page 8

Moulding & millwork manufacturer OPTI-KAP 5003 Optimizing cross-cut saw Automated feeding system SORTING BELTS Detection of defects and quality This Opti-Solution is an optimizing cross-cut line consisting of an automatic infeed system model Opti-Feed 6000. The infeed system automatically feeds the workpieces to a Microtec Goldeneye 502 scanner including x-ray, for detection of defects and quality. Through a queue control system, the workpieces are then transported to four optimizing cross-cut saws model Opti-Kap 5003, that cuts the workpieces into moulding and millwork components. The...

Open the catalog to page 9

Furniture manufacturer OPTI-KAP 5003 Optimizing cross-cut saw OPTI-STACK 3000 Automated stacking system SORTING BELTS Detection of defects and quality Automated feeding system This Opti-Solution is an optimizing cross-cut line consisting of an automatic infeed system model Opti-Feed 6000. The infeed system feeds the raw material to a moulding machine, that splits the workpieces into lamellas. After the moulder, the lamellas are automatically singulated and transported to a Microtec Goldeneye 501 scanner, for detection of defects and quality. Production: Furniture Through a queue control...

Open the catalog to page 10

Additional products System TM A/S All products and system solutions from System TM can be equipped with an automatic handling or scanning system for best lumber utilization and capacity, with a minimum use of labor power. In order to meet all customer demands, our range of material handling systems consist of both standard and fully customized system solutions. All products and system solutions from System TM can be equipped with an automatic scanning system for best lumber utilization and production optimization. The scanner partner of System TM is a technology leader within the scanning...

Open the catalog to page 11All System TM catalogs and technical brochures

-

Opti-Feed

11 Pages

-

Opti-Kap

13 Pages

-

OPTI-STACK

11 Pages

-

Opti-Joint H-200

11 Pages