Catalog excerpts

Automated finger-jointing systems Optimization of staff and wood resources

Open the catalog to page 1

Opti-Joint H-200 Opti-Joint H-200 Shaper Details Opti-Joint V-8 Opti-Joint V-8 Shaper Details Finger-jointing machines A System TM Opti-Joint horizontal or vertical finger-jointing machine ensures optimal utilization of your staff and wood resources. The Opti-Joint finger-jointing machines joint uniform-quality workpieces into a customized quality board at a very high capacity. System TM’s machine technologies provide our customers a high return on their investment when grading their lumber to achieve a customized grade for strength, quality and/or visual look of their end product. The...

Open the catalog to page 2

Opti-Joint H-200 Horizontal finger-jointing machine - Opti-Joint H-200 The Opti-Joint H-200 is a heavy-duty horizontal finger-jointing machine, characterized by an extremely high production capacity and machine utilization in terms of soft- and hardwoods. The finger-jointing machine is manufactured in a particularly durable fashion with mechanical and electrical components of high quality. Why choose an Opti-Joint H-200 from System TM: High capacity, maximum precision and jointing quality Intelligent control system to ensure highest machine utilization and performance Complete hard- and...

Open the catalog to page 3

Opti-Joint H-200 Shaper Details Heavy cast iron construction of the shaper body for high stability. This consists of scoring, hogging and shaping units. It provides high precision adjustment of all units and belt drive supervision for tool protection. Component glue processing. System TM collaborates with all leading suppliers of glue application. Every glue system is determined in close collaboration with every customer and glue application supplier. Optimization of staff and wood resources Multi touch screen including an extensive range of machine & production statistics. System TM...

Open the catalog to page 4

The heavy-duty design of the finger-jointing machine is produced with mechanical and electrical components of high quality, providing the highest level of stability and precision for the tooling and jointing in all workpiece dimensions. The mechanical- and software control design of the Opti-Joint V-8 vertical finger-jointing machine is developed based on the extensive experience of System TM in relation to handling small workpieces at a high capacity. This is controlled by intelligent software which minimizes machine stops and guarantees high machine utilization in terms of available...

Open the catalog to page 5

Opti-Joint V-8 Shaper Details Touch screen which includes an extensive range of machine and production statistics, quick alarm overview. Quick, easy and accurate production changeover between fixed parameter sets per workpiece dimension. Optimization of staff and wood resources The shaper frame supports the linear guides carrying the servo-driven shaper trolley throughout the entire transportation process. It ensures steady and precise movement at a high speed. Component glue processing. System TM collaborates with all leading suppliers of glue application. Every system is determined in...

Open the catalog to page 6

Opti-Joint Press Details Cross-cut saw which includes fixed positioning of the workpieces for the purpose of pre-cutting to lengths before press station. Hydraulic press station for strong and correct press force. To keep workpieces from shifting position during the press process, they are supported by mechanical guiderails from all sides. Optimization of staff and wood resources Pre-press and press frame manufactured in heavy-duty design to prevent deflection during operations. Two channel press system to achieve high capacity. During final pressing of a workpiece, the subsequent workpiece...

Open the catalog to page 7

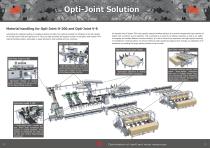

Opti-Joint Solution Material handling for Opti-Joint H-200 and Opti-Joint V-8 Automating the material handling of workpieces before and after the machines enables the utilization of the full capacity of the Opti-Joint H-200 and Opti-Joint V-8. Thus, this also minimizes the required number of operators. With System TM’s material handling system, automation is easily achieved in both existing and new machines. An essential role of System TM’s high-capacity material handling solutions is to provide exceptionally high machine utilization with a minimum use of operators. This is achieved as a...

Open the catalog to page 8

cal Data Overview of the data for Opti-Joint H-200 & V-8 System TM A/S All products and system solutions from System TM can be equipped with an automatic handling or scanning system for best lumber utilization and capacity, with a minimum use of labor power. In order to meet all customer demands, our range of material handling systems consist of both standard solutions and fully customized system solutions. Opti-Feed Opti-Kap *( ): Additional options Automated feeding systems Optimizing cross-cut saws All of the above data can be customized upon request Opti-StackAutomated stacking...

Open the catalog to page 9

System TM service System TM service is a key strategic business unit. The service department focuses on providing you with service and support and we continuously develop our services to meet your requirements. System TM service offer you services to ensure uninterrupted operation, with the best possible productivity and utilization. Systematic maintenance minimizes production downtimes, and ensures smooth operation with minimum risk of surprises. System TM service is a team of professionally educated, trained and experienced service engineers and technicians ready to provide full technical...

Open the catalog to page 10

System TM A/S Skovdalsvej 35, P.O. Box 249 DK-8300 Odder, Denmark Phone: + (45) 86 54 33 55 Fax: + (45) 86 54 32 19 E-mail: tm@systemtm.com www.systemtm.com *System TM cannot be held responsible for any misprints or omissions (Not available for sale in Germany) Optimization of staff and wood resources

Open the catalog to page 11All System TM catalogs and technical brochures

-

Opti-Feed

11 Pages

-

Opti-Kap

13 Pages

-

Opti-Solutions

13 Pages

-

OPTI-STACK

11 Pages