Catalog excerpts

Syntron Material Handling Vibrating Screens Performance Excellence

Open the catalog to page 1

Syntron® Vibrating Screens Syntron Material Handling Proven Engineered Products – Complete Material Handling Solutions SS & SG Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Screen Options Foundry Shakeouts Grizzly Bar Screens

Open the catalog to page 2

Proven Engineered Products – Complete Material Handling Solutions Two powerful industry leading brands—Link-Belt® and Syntron®—have come together under a new company name, Syntron Material Handling, LLC, for one goal – better engineered products. Levine Leichtman Capital Partners, the new owner of Syntron Material Handling, is committed to the success and growth of the company by investing in engineering capabilities, manufacturing efficiency, and customer service. Established in May 2014, Syntron Material Handling (SMH) was built out of the legacies of Link-Belt® Company and Syntron...

Open the catalog to page 3

Link-Belt® Models UP, VC & NRM Inclined Vibrating Screens For separating solids from liquids and sizing light, fine materials. Link-Belt® Models UP, VC and NRM Inclined Vibrating Screens are backed with over 50 years of proven, dependable performance in industry. Continuing Vibrating Screen design improvements by our research and development engineers have enabled these rugged units to solve a greater range of difficult screening problems more effectively and economically. There is a Vibrating Screen type and model for every material characteristic, operating condition and capacity...

Open the catalog to page 4

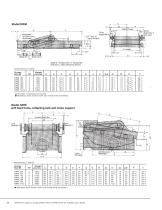

Model UP Sizing and Scalping Screen Foundries, mining installations, feed mills, fertilizer plants, brick plants, quarries and many other industries. Available with one or two decks, the Model UP is designed for fast, accurate sizing or scalping and uniform distribution of light or fine materials. Fully enclosed units can be furnished for processing dusty, corrosive or toxic materials. In this exclusive design, the enclosure is totally isolated from vibration to preserve its structural integrity. Enclosures are supplied complete with feed chute, discharge chute and collecting hopper. The...

Open the catalog to page 5

A Number of springs per bracket. Dimensions subject to change without notice. Certified prints are available upon request.

Open the catalog to page 6

Sizing and Scalping Screen (continued) arts deck, enclosed A ▲ Screen may be factory mounted at 25*, 27-1/2*, or 30* within the enclosure.

Open the catalog to page 7

Dewatering Vibrating Screen Corn, beans, peas, sprouts, beets, diced meats and many other food products. The Model VC vibrating screen is designed for fast, sanitary dewatering of vegetables and other food products. The high-speed, unbalanced vibrator provides a smooth flow of material, forming an Model VC can be supplied with either a welded panel or perforated plate screening surface. This helps maintain sanitation by eliminating material catching tension plates, tension bolts and nuts. The vibrator features large, self- aligning bearings fully enclosed by labyrinth seals. These seals...

Open the catalog to page 8

Model NRM Liquid Vibrating Screen Canning, meat packing, general food processing, sewage treatment, pulp and paper production, juice and oil extraction, distilling and many other industries. NRM liquid vibrating screens use fine screen cloths, up to 120 mesh. Maximum liquid passing with minimum blinding is assured. Separation of solids from liquids is highly efficient. Model NRM screens are built for a long, productive life. The screen box and deck are made of welded, low alloy steel, reinforced with heavy-duty pipe. High strength, spring-loaded bolts assure constant tensioning of the...

Open the catalog to page 9

Alc^ U' vesicalard I'V hcrlzorrtHl nlHHi.wrnp .IHIH".^ r-l'HHiwiui qhtijwvi. Stainless steel screen cloth and V-belt drive furnished . Dimensions subject to change without notice. Certified prints are available upon request.

Open the catalog to page 10

Inclined Vibrating Screens High tonnage units for sizing and scalping. Performance engineered Link-Belt® Models inclined Vibrating Screens assure efficient, dependable operation to solve your most difficult sizing, scalping, dewatering and rinsing applications. These four ruggedly constructed Vibrating Screen models provide medium and heavy- duty service screening a wide range of materials in the coal, aggregate, asphalt, pulp and paper and chemical handling ■ Model RVS Vibrating Screens offer maximum particle segregation of aggregates, chemicals, coal and many other bulk materials. ■ Model...

Open the catalog to page 11

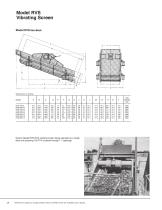

Vibrating Screen A rotary vibrator drive unit with maximum screening area for aggregates, chemicals, coal and many other bulk materials. Model RVS offers you maximum particle segregation. This unit owes screening area and reduced drive powerful rotary vibrator drive unit. The rotary vibrator consists of an electric motor with adjustable eccentric weights on each end. The vibrator's extra-heavy duty bearings are totally enclosed by a dust-tight, water-tight case. Grease lubrication is through easily accessible fittings. Each rotary vibrator is mounted rigidly to the screen frame by six high-...

Open the catalog to page 12

Eight Syntron Model RVS-1512-K vibrating screens equipped with 14- mesh slotted cloth, each producing fireclay with shale.

Open the catalog to page 13

Vibrating Screen Syntron Model RVS-2510 vibrating screen being operated as a single deck unit screening 150 TPH of gravel through 1V openings. Dimensions subject to change without notice. Certified prints are available upon request.

Open the catalog to page 14

Vibrating Screen For medium to heavy-duty sizing, scalping, dewatering and rinsing. Serving industries that include aggregate, mining, pulp and paper Model CS Vibrating Screens are extremely versatile. Available with a variety of screening surfaces, CS Vibrating Screens assure fast, accurate sizing, scalping, dewatering and rinsing of a wide range of materials such as stone, coal, asphalt, pulp and paper and chemicals. To meet specific processing needs, units can be furnished with one, two or three screening decks. several ways; inclined floor mounting, ceiling mounting or combined floor...

Open the catalog to page 16All Syntron Material Handling catalogs and technical brochures

-

Syntron® Vibrating Conveyors

24 Pages

-

Vibrating Screens Catalog

36 Pages

-

Screw Conveyor Catalog

6 Pages

-

Bin Vibrator Catalog

30 Pages

-

Paper Joggers Catalog

20 Pages

-

Material Handling

2 Pages

-

Vibrator Flowaids

30 Pages

-

Syntron Vibrating Tables

6 Pages

-

Syntron Vibrators

48 Pages

-

Syntron Screen Feeders

6 Pages

-

Belt Conveyor Idler

160 Pages

-

Syntron High Velocity

2 Pages

-

Syntron Jogger

20 Pages

-

CEMA Series E4000 Idlers

36 Pages

-

CEMA Series C2000 Idlers

22 Pages

-

CEMA Series B2000 Idlers

22 Pages

-

Ball Bearing Idlers

8 Pages

-

Working with Isolation

20 Pages

-

Aggregates

20 Pages

-

Coal Handling

20 Pages

-

Syntro-Flo

2 Pages

-

Link-Belt Bucket Elevator

26 Pages

-

Working with Hoppers

28 Pages

-

Syntron Power Pulse Control

2 Pages

-

C2000

2 Pages

-

Link-Belt Screw Conveyor

101 Pages

-

Link-Belt Underground

32 Pages

-

Link-Belt Idler

160 Pages

-

Syntron® Vibrators

48 Pages

Archived catalogs

-

PowerPulse WT

2 Pages

-

HV-10

2 Pages