Catalog excerpts

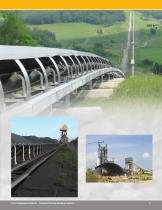

Material Handling Proven Engineered Products - Complete Material Handling Solutions

Open the catalog to page 1

Contents Underground Solutions Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Discharge and Transfer Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Rigid Belt Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Conveyor Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Syntron® MF Direct-Drive Electromechanical Feeders . . . . . . . . . . 8 Conveying and Processing Link-Belt® Idlers . . ....

Open the catalog to page 2

The World’s Best Material Handling Equipment for the Coal Industry When you’re ready to purchase new feeders and idlers – performance, price, quality and dependability certainly impact your decision. Equally important is the name on the Product – Syntron Material Handling. Respected as a Coal Industry leader, Syntron® and Link-Belt® are names you can trust. Always have been. Our company name is new, however, the Syntron® and Link-Belt® business principles remain the same. Quality. Quality. Quality. Whether built in the early 1900’s or today, every Link-Belt® and Syntron® product is truly a...

Open the catalog to page 3

Underground Solutions Drives Link-Belt® drives provide the energy needed to move a loaded conveyor belt throughout the length of the system. Drives consist of pulley skids, power modules and electrical controls. Power modules are modular in construction such that one, two, three or four modules can be attached to the ends of the drive pulleys depending on the total horsepower requirements of the conveyor drive. Syntron Material Handling provides many types of drive configurations that can be combined with our innovative variable frequency drive (VFD) control systems. Remote conveyor drives...

Open the catalog to page 4

Underground Terminal Equipment • Discharge sections • Drives • Electrical controls • Belt storage • Take-ups • Winches • Tail sections • Belt winders • Loading sections • Pulleys Proven Engineered Products – Complete Material Handling Solutions

Open the catalog to page 5

Underground Solutions Rigid Belt Structure Larger volumes of tonnage being produced by improved mining techniques created a need for heavier conveyor construction to handle these loads, while maintaining flexibility and short move-up times. Link-Belt® rigid channel construction fulfills these requirements. Rigid stringer construction can be furnished using 3” - 6” channel as required. Both floor mounting and roof mounting are available. Roof-Hung Rigid Structure Floor Mounted Rigid Structure Proven Engineered Products – Complete Material Handling Solutions

Open the catalog to page 6

Underground Solutions Control Products Conveyor Control Systems Because power transmission affects the performance, cost and reliability of conveying systems, Syntron Material Handling pairs Link-Belt® drives with state-of-the-art controls to deliver outstanding control and reliability for starting, running and stopping conveyor belts. Each control system is custom designed to meet specific operating requirements/environments. Link-Belt® controls provide value through technology. Whether the requirements are a simple control system, or a complex automated information system, we’ll provide a...

Open the catalog to page 7

Underground Solutions MF Direct-Drive Electromechanical Feeders Syntron® MF Direct-Drive Electromechanical Feeders are the heavy-weights of bulk material handling and are used for higher capacity requirements. The ten heavy-duty models handle capacities from 600 to 4,000 tons per hour.* Syntron® MF Direct-Drive Electromechanical Feeders combine extra structural strength with durable components. The deep wing plates form a bridge between inlet and discharge suspension supports, providing extra strength for years of dependable service. Standard troughs feature unitized weldments – one-piece,...

Open the catalog to page 8

Syntron® MF-600 Electromechanical Feeder feeding rock to a crusher. MF Direct-Drive Electromechanical Feeder Features • Operating frequency 1100 VPM at 55.4 Hz • Stroke: 0.25 - 0.30 inches • Dependable, flexible, easily adjustable • Minimal component design to reduce adjustments and replacements due to wear • Quick replacement of Drive Unit • Infinite unbalance adjustment • VFD control providing 10:1 turn-down feed adjustment • Sub-resonant tuning • Stroke consistency and speed stability under varying headload and material dampening • Start and operate fully loaded or empty • Structural...

Open the catalog to page 9

Conveying and Processing Material Handling Solutions Customer Service Our versatile offerings and superior execution reduce operating cost in a variety of material handling industries. Syntron Material Handling has a long history of providing bulk material solutions to industries worldwide. Around the globe, our name is synonymous with problem solving capabilities and material handling expertise. Prompt shipment, on-time delivery, and after-the-sale service are Syntron Material Handling’s trademarks. Timely response to your inquiries and reliable delivery and follow through has built our...

Open the catalog to page 10

Proven Engineered Products – Complete Material Handling Solutions

Open the catalog to page 11

Conveying and Processing CEMA Series C2000 Idlers CEMA Series D3000 Idlers • Rubber double lip contact seal paired with a polymer deflector with integrated labyrinth seal for robust, redundant sealing capability • The outer adjusting nuts are zinc plated, machined steel, to minimize corrosion • Seal works well in dusty conditions and wash down environments Roll Thickness • 5” diameter = 11 ga (0.120) • 6” diameter = 11 ga (0.120) Deep Groove Bearings • Distance from the bearings and shaft ends is minimized to reduce shaft deflection at the bearings. Standard 2RS rubber seals add another...

Open the catalog to page 12All Syntron Material Handling catalogs and technical brochures

-

Syntron® Vibrating Conveyors

24 Pages

-

Vibrating Screens Catalog

36 Pages

-

Screw Conveyor Catalog

6 Pages

-

Bin Vibrator Catalog

30 Pages

-

Paper Joggers Catalog

20 Pages

-

Material Handling

2 Pages

-

Vibrator Flowaids

30 Pages

-

Syntron Vibrating Tables

6 Pages

-

Syntron Vibrators

48 Pages

-

Syntron Screen Feeders

6 Pages

-

Belt Conveyor Idler

160 Pages

-

Syntron High Velocity

2 Pages

-

Syntron Jogger

20 Pages

-

Syntron Vibrating Screens

36 Pages

-

CEMA Series E4000 Idlers

36 Pages

-

CEMA Series C2000 Idlers

22 Pages

-

CEMA Series B2000 Idlers

22 Pages

-

Ball Bearing Idlers

8 Pages

-

Working with Isolation

20 Pages

-

Aggregates

20 Pages

-

Syntro-Flo

2 Pages

-

Link-Belt Bucket Elevator

26 Pages

-

Working with Hoppers

28 Pages

-

Syntron Power Pulse Control

2 Pages

-

C2000

2 Pages

-

Link-Belt Screw Conveyor

101 Pages

-

Link-Belt Underground

32 Pages

-

Link-Belt Idler

160 Pages

-

Syntron® Vibrators

48 Pages

Archived catalogs

-

PowerPulse WT

2 Pages

-

HV-10

2 Pages