Website:

SYNERGYS TECHNOLOGIES

Website:

SYNERGYS TECHNOLOGIES

Catalog excerpts

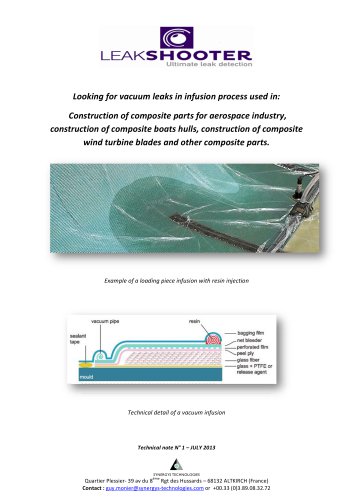

LEAKS HOOTER Ultimate leak detection Looking for vacuum leaks in infusion process used in: Construction of composite parts for aerospace industry, construction of composite boats hulls, construction of composite wind turbine blades and other composite parts. Example of a loading piece infusion with resin injection vacuum pipe - bagging film .perforated film -glass fiber release agent Technical detail of a vacuum infusion Technical note N°l- JULY 2013 SYNERGYS TECHNOLOGIES Quartier Plessier- 39 av du 8 Rgt des Hussards - 68132 ALTKIRCH (France)

Open the catalog to page 1

Problem encountered with vacuum infusion (also named SCRIMP method): Vacuum infusion method consists to inject resin in a closed structure composed of an open mold, topped with a hermetic cover which contains glass fiber or other and all together connected to a vacuum installation. Before infusing the fiber with resin, firstly we have to be sure everything under vacuum pressure (almost between -0.5 et -0.9 Bar) is leak tight. If there are leaks in the plastic cover, then the resin dispersion will not be uniform in the glass fiber which will result in imperfections in the finished product....

Open the catalog to page 2All SYNERGYS TECHNOLOGIES catalogs and technical brochures

-

VSHOOTER®+

4 Pages

-

LKS 1000 V3+PRO

8 Pages

-

LKS CAMERA 1000 V2+IR

4 Pages

-

TS1000

4 Pages

-

CoroCAM 6D

2 Pages

-

CoroCAM 8

2 Pages

-

CoroCAM 7

2 Pages

-

CoroCAM 6D / 6N

2 Pages

-

How to check a steam trap

2 Pages