Catalog excerpts

Precision Mandrels EMK+ D-S

Open the catalog to page 1

SwissChuck mandrels and multi-bla clamping precison that comes fr Mandrel EM Flexibility with interchangeable With the double conical expansion of clamping sleeves The clamping sleeves are interchangea- fect clamping geometry is obtained. ble modular units requiring no re- The repeat accuracy is in the range of 0.01 mm. Special clamping sleeves are also available for clamping profiled, internally toothed, stepped or conical workpieces. Locking element Ground reference diameter Mandrel body EM Parallel keys for positive driving Pull-back action Highlights of the EM series • Expansion of...

Open the catalog to page 2

Multi-blade mandrel D Wide clamping range with perfect clamping Unique wide clamping range offers considerable geometry for tight tolerances. advantages over other conventional clamping Flexible clamping of workpieces with diverse systems. Fewer mandrels are required, shorter bore diameters with the same mandrel and set-up time and greater flexibility. Unique SwissChuck advantage: Wider clamping range per mandrel (up to 15 mm) Axially fixed Mandrel body Highlights of the D series • Wide clamping range Clamping blades • Suitable for automatic loading • Repeatability to 0.01 mm • Axially...

Open the catalog to page 3

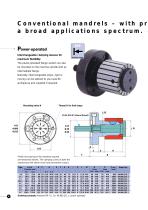

Conventional mandrels – with pr a broad applications spectrum. EM Power-operated Interchangeable clamping sleeves for Pull-back action maximum flexibility. The power-operated flange variant can also be mounted on the machine spindle with an intermediate flange. Naturally, interchangeable stops, rigid or moving can be tailored to your specific workpieces and supplied if required. Thread R for limit stops LØ M (for EM 8C internal thread) Perfect functioning of the mandrels requires pre-tensioned sleeves. The clamping cones of both the mandrel and the sleeve must have permanent contact. Type...

Open the catalog to page 4

Hand-operated Pull-back action A flexible, cost effective and surprisingly efficient alternative. Hand-operated mandrels are used mainly for small series production or as test mandrels. The dimension "G" is toleranced as a size of fit for precise flange mounting. The flange-less version is normally mounted between two 60° centres. Limit stops can be LØ Between centres Type Ordering example: Mandrel EM-6C, 90.841.148.1, hand-operated, flange-less Flange version Type Ordering example: Mandrel EM-6C, 90.800.127.1, hand-operated

Open the catalog to page 5

Modular clamping sleeve range flexible chucking. S tandard clamping sleeves All the clamping sleeves shown can easily be used on all standard mandrels. The clamping sleeves are stocked in a prefabricated condition and are finish-ground when ordered. Thus facilitating speedy delivery. For this reason the nominal size of the workpiece bore with tolerance zone must be clearly stated when ordering. In-house finish-grinding of clamping sleeves: The easiest way to finish-grind a clamping sleeve is on a hand-operated mandrel. However, finish-grinding can also take place Recommended pre-tension for...

Open the catalog to page 6

Special clamping sleeves Particularly difficult problems can be solved Special problem solutions are readily available easily with specially shaped clamping sleeves. For example, extended or profiled clamping sleeves are available with internal toothing or splines for clamping in the base or pitch circle. Also available are segmented clamping sleeves for extremely high transmission forces. few common examples are shown below: Shortened standard type Extended standard type Shortened type with recessed draw bar head External actuation of the clamping sleeve type C9

Open the catalog to page 7

Multi-blade mandrels with highly SwissChuck technology. D Short multi-blade mandrel D-S For short workpieces Axially fixed The clamping blades are all moved together, these mandrels very precisely radially, so that a concentricity of 0.01 mm maximum is provided over the entire clamping range. To generate the axial force, pneumatic or hydraulic cylinders can be used. When equipped with the appropriate attachment Number J Clamping of clamping blades range Attachment for manual actuation Short version Type designation Also for long version Ordering example: Multi-blade mandrel SwissChuck D...

Open the catalog to page 8

Long multi-blade mandrel D-L For long workpieces Axially fixed The clamping blades are all moved together, very precisely radially and so provide a perfect equipped with clamping geometry over the entire clamping range with a concentricity of 0.01mm maximum. attachment these mandrels To generate the axial force, pneumatic or can also be operated manually. hydraulic cylinders can be used. H7 H5 Attachment for manual actuation Long version Type designation Clamping range Number of clamping blades Ordering example: Multi-blade mandrel SwissChuck D 2-60 L Also for short version

Open the catalog to page 9

Special mandrels designed to solve special problems. Special problems require special solutions. SwissChuck has the experience and the technology to deliver workable cost effective solutions. Shown below are just a few examples of the many successful solutions which have been developed recantly: Example 1: Multi-blade double mandrel for long workpieces Example 2: Both clamping groups each with 12 blades Mandrel for holding un-machined clamp concentric and independent of each other, so that workpieces can be adjusted to various diameters. The jaws of the mandrel operating with When the...

Open the catalog to page 10

Example 4: Mandrel type EM/special version, with retractable stop The workpiece "driving wheel" is loaded automatically and monitored by air pressure. It is clamped in the bore and drawn towards the stop, which is moved back when the workpiece is clamped. Machining takes place on all sides. Example 5: Mandrel for small parts with a diameter from about 5 mm. The workpiece is clamped via the slotted sleeve, actuated by the axial pressure of the tailstock centre. Example 3: Expanding mandrels for narrow workpieces, DHL series Expanding mandrels are used preferably for workpieces with bores in...

Open the catalog to page 11

KCHP/VKCHP Precision power chuck LZK/LSK-S Collet chuck with clamping lamellas DL Collet expanding mandrel TGC/FTGC Tool chuck OVEKA Compensating chuck OVEKAV Moving compensating chuck FLD/AFLD Twist finger-type console chuck SPECIAL PRODUCTIONS According to the customers KCHSF Centrifugal force chuck OVEK Precision power chuck KFHP Precision power chuck VMCHP Diaphragm chuck SwissChuck AG Industriestrasse 3 CH-8307 Effretikon SAP zu KCHP Automated vice PZLHM Pneumatic force clamping cylinder

Open the catalog to page 12All SwissChuck AG catalogs and technical brochures

-

400-A

56 Pages

-

OVEKAV / OVARZV

12 Pages

-

OVEKA & KA

8 Pages

-

COLLET SYSTEM LZK-S

8 Pages

-

PRECISION POWER CHUCK KCHP/VKCHP

12 Pages

-

Compensating Chuck – Retractable

12 Pages

-

COMPENSATING CHUCKS

8 Pages

-

PRECISION POWER CHUCK

12 Pages