Catalog excerpts

/mwmwrot ('.wiv.ii msiw filmic CLAMPING TECHNOLOGY SPECIAL SOLUTIONS

Open the catalog to page 1

BESPOKE SPECIAL SOLUTIONS You define the task and we develop and implement the solution! Special clamping chucks are tailor-made products. They are adapted to your specific requirements. The designs are matched to the work piece and to the individual machine concepts. Moreover, at SwissChuck you benefit from know-how that has been gained over decades and from using the most modern technologies. It is our aim to minimise your costs by supporting your manufacturing processes. Special solutions from SwissChuck are d esigned to generate sustained added value. Simply said: our products will let...

Open the catalog to page 2

SwissChuck Precision Workholding Sectors Pages Thumbnails with examples of workpieces

Open the catalog to page 3

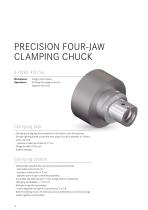

PRECISION FOUR-JAW CLAMPING CHUCK 4 OVEK 450 So Workpieces: Operations: Polygon tool holders Grinding the polygon and the adjacent front end Clamping task – Clamping and aligning the workpieces in the flanks of the four grooves – Enough opening stroke to load the work piece C6 with a diameter of 130mm at the rear end · requires a radial jaw stroke of 41 mm – Plunge for ø90 of 200 mm – Stable clamping Clamping system – Hydraulically operated four-jaw chuck with special functions · fast radial stroke of 39 mm · precision radial stroke of 2 mm · opposite pairs of jaws controlled separately –...

Open the catalog to page 4

OVEK 450 Clamping position SwissChuckPrecision Workholding / Suitability as per machining process: Eccentric grinding Combination V turning/hard turning Explanation of symbols: SwissChuck.com Technical characteristics Number of lines: • Hydraulic 4

Open the catalog to page 5

TOOL GRIND CHUCK OFTGC 2-30 So | 18-36 So | 34-52 So Work pieces: Operations:  HSS or HM tap HSS or HM drill HSS or HM cutter Grinding tools of solid material Clamping task – Centric holding of blanks with high run-out accuracy – Stable clamping of the work pieces – Covering a wide clamping range Clamping system – Hydraulically operated collet chuck – Precision interface between clamping chuck and add-on parts – Aligning not necessary – Clamping range with three chucks from 2 mm to 52 mm – Clamping chuck is protected and lubricated by an oil-carrying air purge s ystem against

Open the catalog to page 6

Suitability as per machining process: A Cylindrical grinding OFTGC OFTGC 2-30 So | D Hard turning turning/hard turning Explanation of symbols: SwissChuck.com Technical characteristics Outside diameter Overall height Max. rpm Max. clamping force Run-out accuracy Number of lines: • Hydraulic • Pneumatic Pressure up to

Open the catalog to page 7

COMPENSATING LEVER CHUCK Suitability as per machining process: Work pieces: Operations:  Eccentric grinding HSS or HM tap HSS or HM drill HSS or HM cutter Grinding tools of solid material E Combination turning/hard turning Explanation of symbols: SwissChuck.com Clamping task – Positioning of the blanks between centers – Precise, deformation-free clamping of the work pieces at the width across flats – Covering a wide clamping range Clamping system – Hydraulically operated lever chuck – Slip stick free movements of the levers – Interchangeable centre points with precision interface –...

Open the catalog to page 8

Suitability as per machining process: 2x3 ZLH 180 So Work pieces: Operations:  Shafts for textile machines Turning the complete shaft end C Turning E Combination turning/hard turning Explanation of symbols: SwissChuck.com Clamping task – Stable and precise clamping at defined clamping positions – Prevention of disruptions or damage to the work pieces, caused by swarf Clamping system – Cylinder operated chuck with 2 x 3 centrically inclined bolts – Use of a bell with pre-centring disk in order to prevent swarf entering the clamping area – Strong and stable clamping by applying the inclined...

Open the catalog to page 9

HYDRAULICALLY OPERATED INDEXING CHUCK 3 HSKCHS 400 So Work pieces: Operations: Various pump casings Turning the centric and eccentric inside diameters and the adjacent end faces Clamping task – Clamping the work piece on a short, cylindrical surface – Positioning by a positioning pin in a manufacturing bore – It must be possible to manufacture eccentric dimensions 5.0, 6.3, 8.0, 10.0, 12.6 and 16.0 mm – The flatness deviation of the end faces may not exceed 0.01 mm. – High run-out accuracy – Stable clamping Clamping system – Hydraulically operated three-jaw indexing chuck – turnable inside...

Open the catalog to page 10

SwissChuckPrecision WorkholdingSuitability as per machining process: A Cylindrical grinding Explanation of symbols: SwissChuck.com Technical characteristics Number of hydraulic lines 8

Open the catalog to page 11

HYDRAULICALLY OPERATED CONSOLE AND COMPENSATING CHUCK 2 OVEK-M 270 So Work pieces: Control lenses to hydraulic pumps Operations: Grinding the spherical shape and the bore Clamping task - Referencing the control lenses: ■ in the bore ■ to the radius at the back ■ optionally: - to the center plane of the side surfaces (centric clamping) - at the lower side surface (console type clamping) - Clamping at the side surfaces with hardly any deformation Clamping system - Hydraulically operated two-jaw chuck - Hydraulically controllable function changing between centric and console type clamping -...

Open the catalog to page 12

SwissChuckPrecision Workholding /Suitability as per machining process:A Cylindrical grinding Eccentric grinding Hard turning turning/hard turning Explanation of symbols: SwissChuck.com Technical characteristics Outside diameter 292/270 mm Displacement stroke of the centring plunger 25 mm Number of hydraulic lines 6

Open the catalog to page 13

PRECISION INDEXING CHUCK HSCH 280 So Work pieces: Operations: Hydraulic motor shaft Grinding the eccentrically placed ball sockets Clamping task – Clamping the body at the outside diameter – Axial end stop at the shoulder – Checking for presence of the workpiece at the axial end stop – Precise sevenfold, partial indexing – High positioning accuracy – Manual or automatic loading Clamping system – Hydraulically operated sevenfold precision indexing chuck – Indexing around eccentric axis – Interlocking the indexing positions free of play, with monitoring – Interchangeable axial end stops with...

Open the catalog to page 14All SwissChuck AG catalogs and technical brochures

-

400-A

56 Pages

-

OVEKAV / OVARZV

12 Pages

-

OVEKA & KA

8 Pages

-

Precision Mandrels EM + D

12 Pages

-

COLLET SYSTEM LZK-S

8 Pages

-

PRECISION POWER CHUCK KCHP/VKCHP

12 Pages

-

Compensating Chuck – Retractable

12 Pages

-

COMPENSATING CHUCKS

8 Pages

-

PRECISION POWER CHUCK

12 Pages