Catalog excerpts

ENGLISH Electric wire rope hoists Crane components Controlling/Monitoring

Open the catalog to page 1

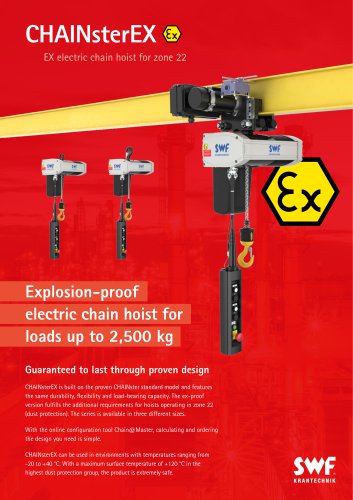

30 Controlling/ Monitoring CraneKit Crane components CRABster Winch End carriages BLOCKster Travelling machineries NovaMaster TravelMaster RadioMaster Sway Control Tandem operation NOVA Electric wire rope hoists Look ahead! 03 SWF is one of the leading global players in crane and hois ting equipment. At all times and in all places, SWF applies to the highest and the most demanding standards – those of our customers. Our customers are independent crane manufacturers, lifting equipment resellers and service companies. They use SWF hoists and components because they perform better, offer...

Open the catalog to page 2

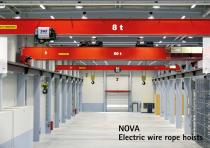

NOVA Electric wire rope hoists

Open the catalog to page 3

NOVA Electric wire rope hoists for loads of up to 80 t • Optimum utilisation of space Compact installation dimensions and optimum approach dimensions, minimum hook dimensions • Precise and safe work Minimum lateral hook movements and low load swing thanks to smooth load movement with frequency inverters NOVA NOVA The brake designed to extend the lifetime, the larger diameter of the rope drum to protect the load rope, the hoist gear lubricated to extend the lifetime and the smooth cross travelling with the frequency inverter reduces material wear and tear Advantage: Maximum cost...

Open the catalog to page 4

NOVA Perfect utilisation of space and almost vertical lifting guarantee so that work is carried out precisely and safely. Minimum hook travel We have increased the size of the drum, making everything else smaller. The main feature of our NOVA electric wire rope hoist is the extremely large diameter of the rope drum, which provides first-class protection of the rope, but there are also other features which guarantee safe and very cost-effective use. Best approach dimensions Hoisting gear limit switch Contactor control with NovaMaster Stainless steel hoist panel NOVA adapts itself to your...

Open the catalog to page 5

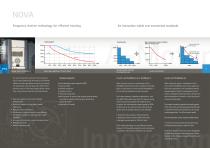

NOVA Frequency inverter technology for efficient hoisting An innovation which sets economical standards Hoisting Speed Running Time Speed comparison between A-Motor and pole change motor NOVA Speed range comparison A, S and P motors The use of frequency inverters for the hoisting process increases productivity. This leads to an extended lifetime of motors and brakes as well as cost savings for maintenance work and spare parts. Furthermore, the hoist works in a far more energy efficient manner than a conventional contactor-controlled solution. • Safe hoist speeds for the smooth handling of...

Open the catalog to page 6

CRABster Winch

Open the catalog to page 7

CRABster Winch for loads up to 250 t • Precise and safe operation Hoist condition monitoring system NovaMaster as overload protection with strain gauge load measuring, hoisting frequency inverter with closed loop, hoisting motor with encoder, frequency inverter controlled travelling machineries • Optimal usage of space and equal wheel load distribution Compact design and optimal approach dimensions, no horizontal hook movement • Various design options • Loads up to 250 t • Four frame sizes • Available as a solo winch or with a crane kit • Double girder trolley or fixed hoist • True vertical...

Open the catalog to page 8

CRABster Well thought-out technology and powerful components guarantee maximum safety and efficiency. State-of-the-art electrics The CRABster winch is delivered complete with control panels, all of which are pre-bolted and pre-wired accordingly. Standardised modules are used depending upon the performance features of the crane or of the individual winch. In the case of an individual winch, one control panel remains free for the individual equipment. The main components of the control panel are the frequency inverters for crane and trolley travelling, as well as lifting and lowering, the...

Open the catalog to page 9

CraneKit Crane components End carriages BLOCKster Travelling machineries

Open the catalog to page 10

CraneKit Crane components for loads up to 80 t • High efficiency One-Stop-Shopping principle: All components from one source • Shorter assembly times Pre-designed, pre-assembled and pre-wired components with screw and plug connection (plug and socket) • Numerous variations A well planned standard component basis, depending on the usage with electric chain or electric wire rope hoist, crane calculation support via CraneMaster software Crane light for bridge Advantage: a complete crane in an “All round-Carefree-Package”, Power – out of the box • Plug-in adapters and couplings for all...

Open the catalog to page 11

CraneKit Component packages for single and double girder overhead travelling bridge cranes as well as underslung and gantry cranes Energy chain as power supply Innovations. Always one step ahead. SWF components also stand out due to their continuous further development. New technologies and technical implementations can primarily be evident in the SWF crane kits: • Frequency inverters for lifting/lowering and travelling • Synchronisation when lifting/lowering • Tandem function through crane communication • Electronic load swing damping • New end carriage and bridge panels • Power supply and...

Open the catalog to page 12

CraneKit Crane types Single girder underslung travelling crane Double girder underslung travelling crane Single girder overhead travelling bridge crane Double girder overhead travelling bridge crane Wall console crane Gantry crane Semi gantry crane

Open the catalog to page 13

End carriages Overhead crane end carriages for loads of up to 250 t Underslung crane end carriages for loads of up to 20 t End carriages for single girder overhead travelling bridge cranes End carriages for double girder overhead travelling bridge cranes • Primer coating, for single and double girder overhead cranes • For new cranes and modernisations • Various connection possibilities • Running wheels in grey cast iron EN-GJS-700 (GGG70) • Two and four wheel versions (Bogie) • Anti-drop devices, storm protection, lateral guide rollers and rail guards all optional Wheel diameter mm 90 110...

Open the catalog to page 14

Travelling machineries Wheel blocks for static loads of up to 30 t Constant and reliable movement for customised systems Screw-on head connection H, without additional costs Welded connection W, without additional costs Inserted connection I, as an option Screw-on connection S / affixed connection A, as an option • Six sizes to suit the required wheel load • Wheels in grey cast iron EN-GJS-700 (GGG70) • Driven or idle • Various connection types • Maintenance-free roller bearings • Painted in RAL 7021 • Designed for new systems and modernisations Wheel diameter Max. static wheel load...

Open the catalog to page 15All SWF Krantechnik GmbH catalogs and technical brochures

-

ProfileMaster-PLUS_EN

12 Pages

-

Light Cranes/Chain Hoists

32 Pages

-

CRAFTster hand chain block

2 Pages

-

CRAB ster

8 Pages

-

BLACKLINE

7 Pages