Catalog excerpts

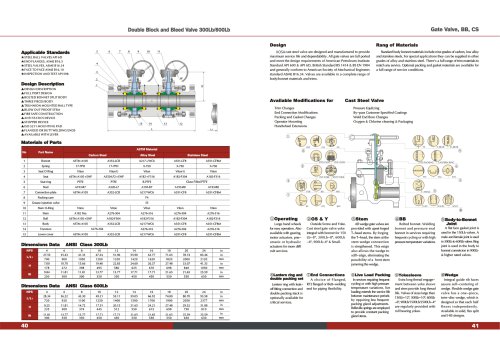

Gate Valve, BB, CS Applicable Standards ★ STEEL BALL VALVES API 6D ★ END FLANGES, ASME B16.5 ★ STEEL VALVES, ASME B16.34 ★ FACE TO FACE ASMEB16.10 ★ INSPECTION AND TEST API 598 Design Description ★ DESIGN DESCRIPTION ★ FULL PORT DESIGN ★ BOLTED BONNET SPLIT BODY ★ THREE PIECES BODY ★ TRUNNION MOUNTED BALLTYPE ★ BLOW OUT PROOF STEM ★ FIRE SAFE CONSTRUCTION ★ ANTI STATICS DEVICE ★ STOPPER DEVICE ★ ISO 5211 MOUNTING PAD ★ FLANGED OR BUTT WELDING ENDS ★ AVAILABLE WITH LEVER Design KOSAcast steel valve are designed and manufactured to provide maximum service life and dependability. All gate valves are full ported and meet the design requirements of American Petroleum Institute Standard API 600 & API 6D, British Standard BS 1414 & BS EN 1984 and generally conform to American Society of Mechanical Engineers standard ASME B16.34. Valves are available in a complete range of body/bonnet materials and trims. Rang of Materials Standard body bonnet materials include nine grades of carbon, low alloy and stainless steels, For special applications they can be supplied in other grades of alloy and stainless steel. There's a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions. Available Modifications for Trim Changes End Connection Modifications Packing and Gasket Changes Operator Mounting Handwheel Extensions Cast Steel Valve Pressure Equlizing By-pass Customer Specified Coatings Weld End Bore Changes Oxygen & Chlorine cleaning & Packaging Dimensions Data ANSI Class 300Lb 4 (DOperating Large hand wheels for easy operation. Also available with gearing, motor actuators, pneumatic or hydraulic actuators for more diffi cult services. (§)OS & Y Outside Screw and Yoke. Cast steel gate valve yoke integral with bonnet for 150 Lb-8", 300Lb-8", 600Lb -6", 900Lb-4" & Small. ©Stem All wedge gate valves are provided with upset forged T-head stems. By forging the T-head, the stem at the stem wedge connection is stregthened. This esign also allows the wedge to sdlf—align, eliminating the possibility of a bent stem jamming the wedge. @BB Bolted bonnet. Welding bonnet and pressure seal bonnet in services requiring frequent cycling or with high pressure temperature variations. (§)Body-to-Bonnet Joint A flat face gasket joint is used in the 150Lb valves. A male and female joint is used in 300Lb to 600Lb valves. Ring joint is used in the body to bonnet connetcion in 900Lb & higher rated valves. Dimensions Data ANSI Class 600Lb 4 ©Lantern ring and double packing set Lantern ring with leak-off fitting connection and double packing stack is optionally available for critical services. ©End Connections A choice of Flanged, RTJ flanged or Butt-welding end for piping flexibility. ©Live Load Packing In services requiring frequent cycling or with high pressure temperature variations, live loading extends the service life between maintenance periods by rqquiring less frequent packing gland adjustments. Belleville springs are employed to provide constant packing gland stress. ©Yokesleeve Extra long thread engagement between yoke sleeve and stem provide long thread life. Valves of sizes large than 150Lb-12", 300Lb-10", 600Lb -6", 900Lb/1500Lb/2500Lb-4" are regularly provided with roll bearing yokes. ©Wedge Integral guide rib faces assure self-centering of wedge. Flexible wedge gate valve has a one-piece, twin-disc wedge, which is designed so that each half flexes independently. Available in solid, flex split and HIS designs.

Open the catalog to page 1All SuZhou KoSa Environmental Protection CO. catalogs and technical brochures

-

round-ear-loop

5 Pages

-

pp-spunbond-non-woven-fabric

6 Pages

-

one-wire-nose-wire

5 Pages

-

n95-n99-n100-meltblown

5 Pages

-

kf80-kf94-kf99-meltblown

5 Pages

-

full-plastic-nose-wire

6 Pages

-

full-aluminimum-nose-wire

4 Pages

-

flat-ear-loop

6 Pages

-

ffp1-ffp2-ffp3-meltblown

5 Pages

-

es-non-woven-fabric

6 Pages

-

double-wires-nose-wire

5 Pages

-

KOSA INDUSTRIAL VALVES Catalog

51 Pages

-

KOSA FILTRATION Catalog

11 Pages