Catalog excerpts

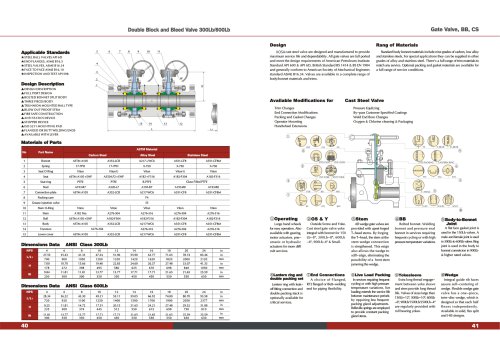

Swing Check Valve, BB, CS Cast Steel Swing Check Valve 150Lb Design KOSACast Steel check valve are designed and manufactured to provide maximum service life and dependability. All check valves are meet the design requirements of American petroleum institute standard API 600 & API 6D, BS EN 13709 and generally conform to American society of mechanical engineers standard ASME B16.34. Valves are available in a complete range of body/bonnet materials and trims. Rang of Materials Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steels. For special applications they can be supplied in other grades of alloy and stainless steel. There's a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions. Available Modifications for Trim changes End connection modifications Gasket changes Outside lever and weight Slam retarders Cast Steel Valve Pressure equlizing Outside lever and weight Customer specified coatings Weld end bore changes Oxygen & chlorine cleaning & packaging Applicable standards: Steel check valves, API 6D Steel check valves, ISO 14313 Steel valves, ASME B 16.34 Face to face, ASME B 16.10 End flanges, ASME B16.5 Butt welding ends, ASME B16.25 Inspection and test, API 598/API 6D Design description: BB, Bolted bonnet, cap Swing type, Anti-rotation disc Renewable seat rings Non-penetrate disc shaft Horizontal or vertical service Flanged or butt welding ends Note: 1). Cast steel disc for NPS 4" and above. 2). NPS 6" & Large; 3). Disc and seat ring may either be solid facing material or a base material equal to or better than the body/bonnet material with facing as shown. (2)End connections A Choice of flanged, RTJ flanged or butt welding end for piping flexibility. ©Outside lever and weight All external hinge pin swing check valves 12" and smaller are available with an optional outside lever and weight. Internal hinge available with all swing check valves (Dbb Bolted bonnet. Welding bonnet and pressure seal bonnet in services requiring frequentcyclingorwith high pressure / tempe-rature variations. Dimensions data Size ©Body-to-bonnet joint A Male and female joint or tongue and groove joint is used 150Lb to 600Lb valves. Ring joint is used in the body to bonnet connection in 900Lb & higher rated valves. ©Seat rings Separate heavy duty, full ported ring for easy maintenance. Screwed or welded connection into body. (7)HCU Weighted mechanical accumulator This design can be used to either dampen or assisist closing of the check valve disc depending on orientation. By using the hydraulic control unit to buffer action the disc, the valve opens at lower flow rates.

Open the catalog to page 1All SuZhou KoSa Environmental Protection CO. catalogs and technical brochures

-

round-ear-loop

5 Pages

-

pp-spunbond-non-woven-fabric

6 Pages

-

one-wire-nose-wire

5 Pages

-

n95-n99-n100-meltblown

5 Pages

-

kf80-kf94-kf99-meltblown

5 Pages

-

full-plastic-nose-wire

6 Pages

-

full-aluminimum-nose-wire

4 Pages

-

flat-ear-loop

6 Pages

-

ffp1-ffp2-ffp3-meltblown

5 Pages

-

es-non-woven-fabric

6 Pages

-

double-wires-nose-wire

5 Pages

-

KOSA INDUSTRIAL VALVES Catalog

51 Pages

-

KOSA FILTRATION Catalog

11 Pages